Production scheduling and machine maintenance optimization method based on joint optimization model

An optimization model and joint optimization technology, applied in constraint-based CAD, design optimization/simulation, instruments, etc., can solve problems such as machine degradation, lack, uncertainty, etc., and achieve the effect of reducing maintenance costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

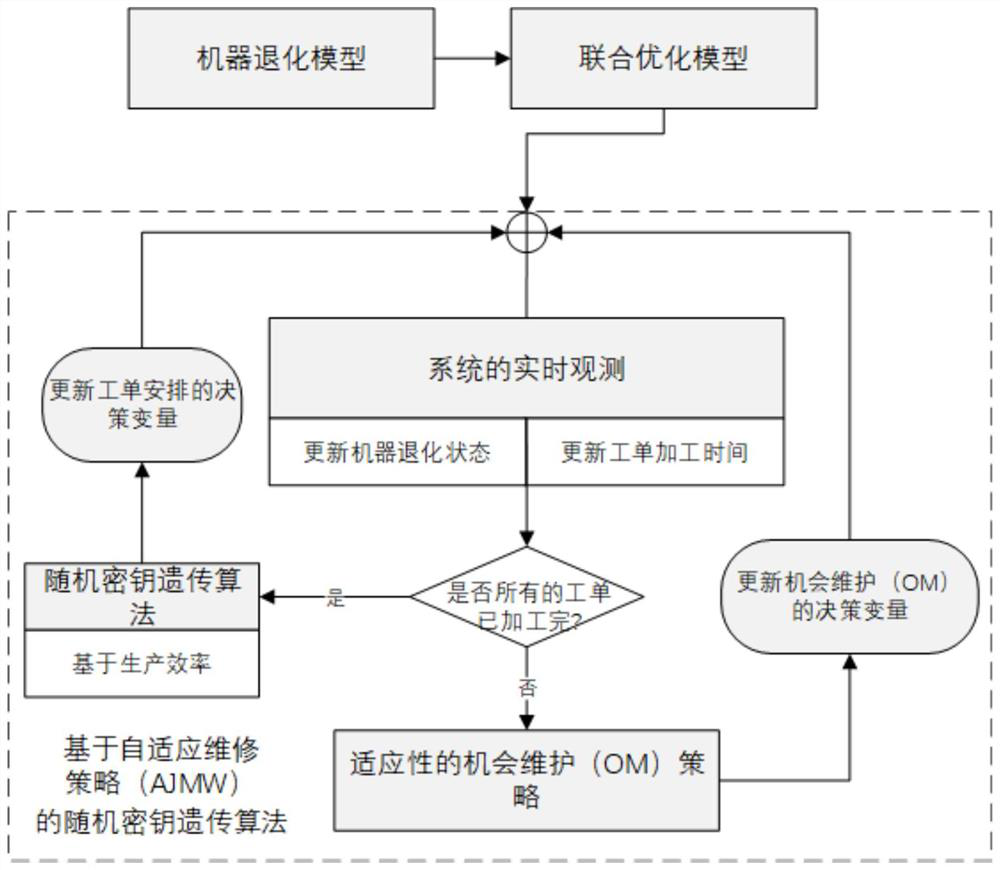

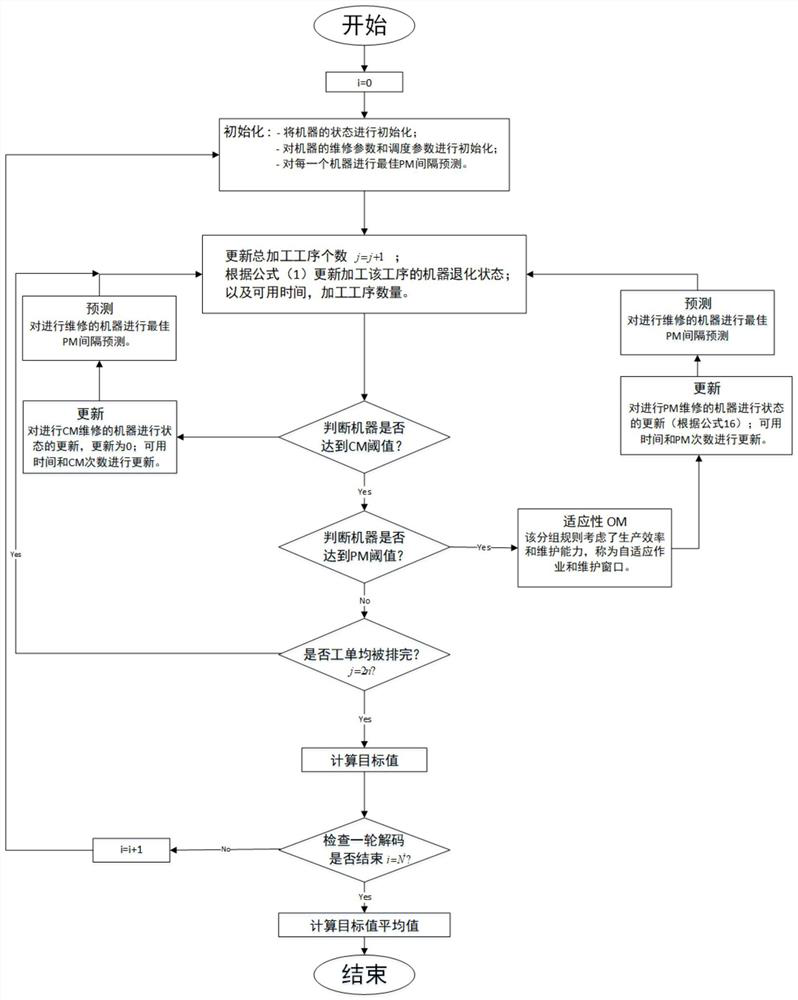

[0055] The invention can carry out modeling and analysis based on the actual data of the factory, and can be applied to the series-parallel mixed two-stage production system for engineering scheduling and maintenance optimization. First, the degradation model of the production machine is constructed; secondly, a joint optimization model of production and maintenance is established that considers the correlation between production and maintenance, so as to realize the modeling and analysis of the production process; then, a method is proposed for this stochastic and dynamic environment. On this basis, a joint optimization method based on meta-heuristic algorithm and self-adaptive maintenance strategy AJMW is designed to solve the joint optimization model of production and maintenance established by the present invention. The implementation process is now analyzed in detail, and the specific implementation methods are as follows:

[0056] 1) Build a production machine degradatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com