Quantitative feeding equipment for processing environment-friendly thermosetting powder coating

A thermosetting powder and coating technology, applied in the fields of plastic recycling, recycling technology, grain processing, etc., can solve the problems of inability to control the feeding weight, inconvenient use, and inconvenient feeding of environmentally friendly thermosetting powder coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

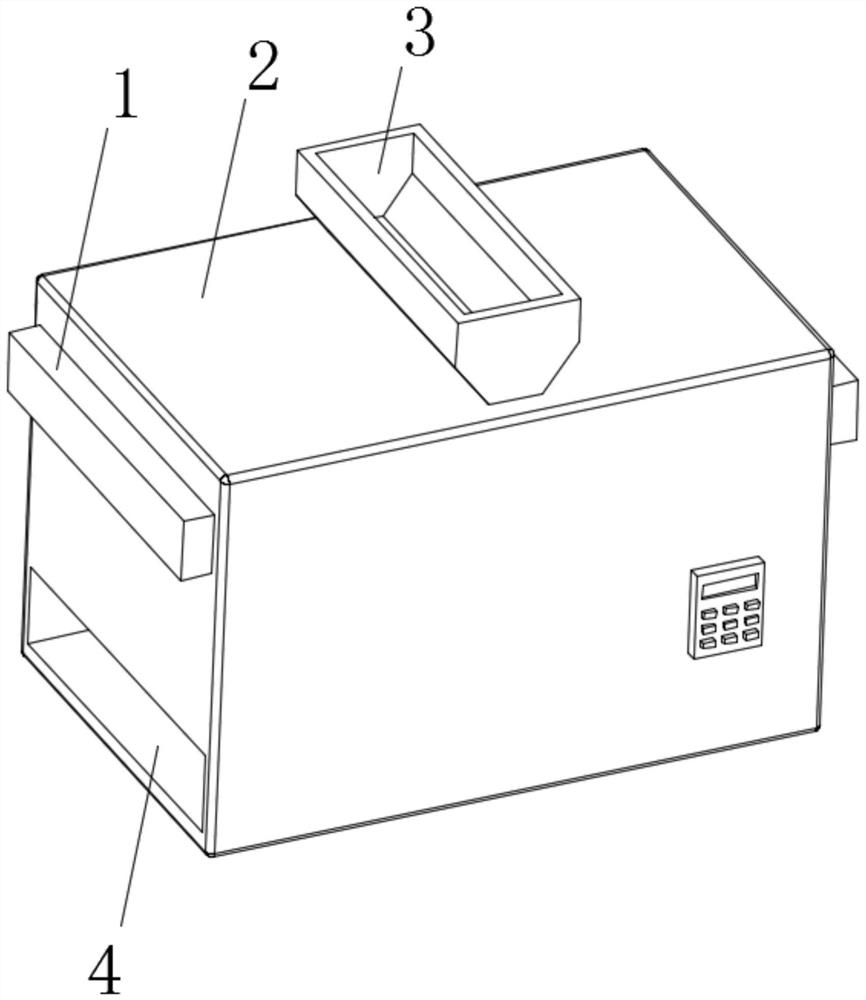

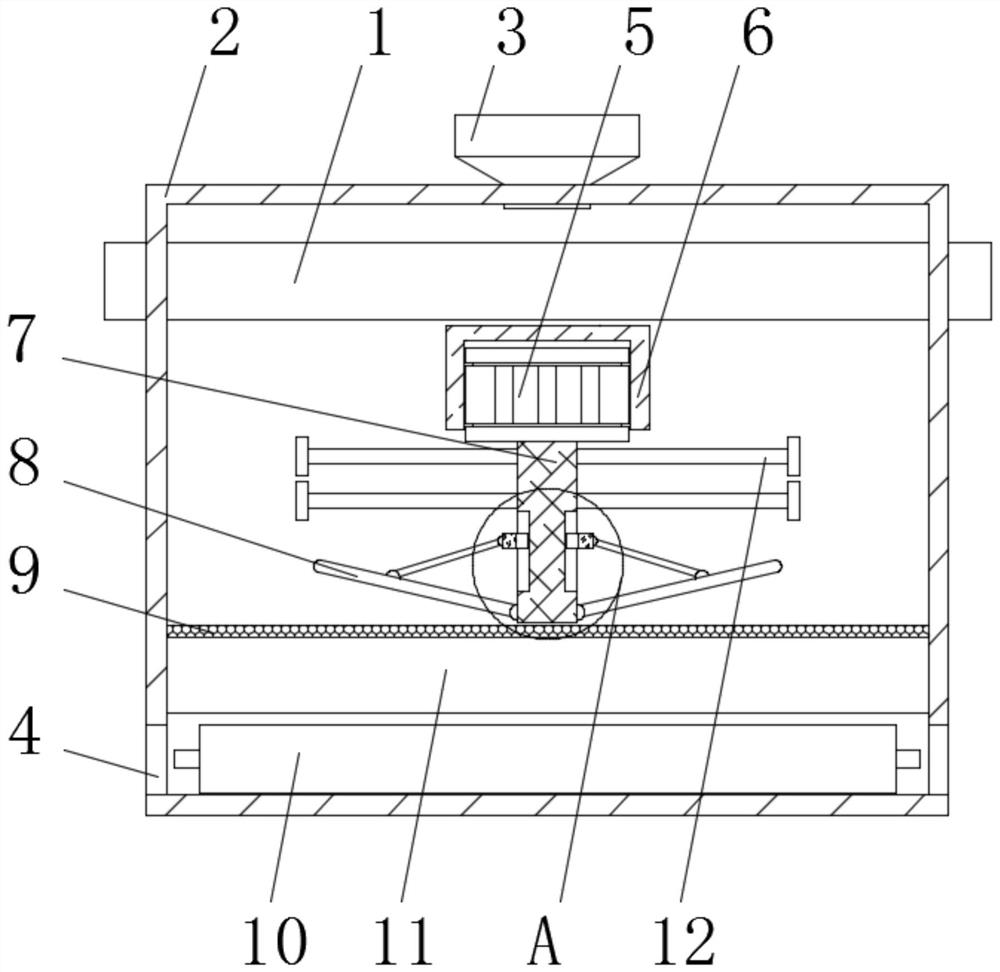

[0034] as Figure 1-5As shown, the present invention provides an environmentally friendly thermoset powder coating processing for quantitative feeding equipment, comprising a feeding box 2, an inlet hopper 3, an outlet 4 and a collection silo 10, the top of the feeding box 2 is embedded with an inlet hopper 3, the left and right sides of the feeding box 2 are opened with an outlet 4, the inner wall of the discharge port 4 slides connected to the collection bin 10, the inner wall of the feeding box 2 and located directly below the feed hopper 3 is provided with a particle crushing frame 1, the left and right ends of the particle crushing frame 1 are inserted through the left and right sides of the outer wall of the feeding box 2, The inner wall of the feeding box 2 is fixed to be connected to the dust cover 6, the inner wall of the dust cover 6 is fixed with a drive motor 5, the drive end of the drive motor 5 is fixed to be connected to the hinge 7, and the outer wall of the hinge 7...

Embodiment 2

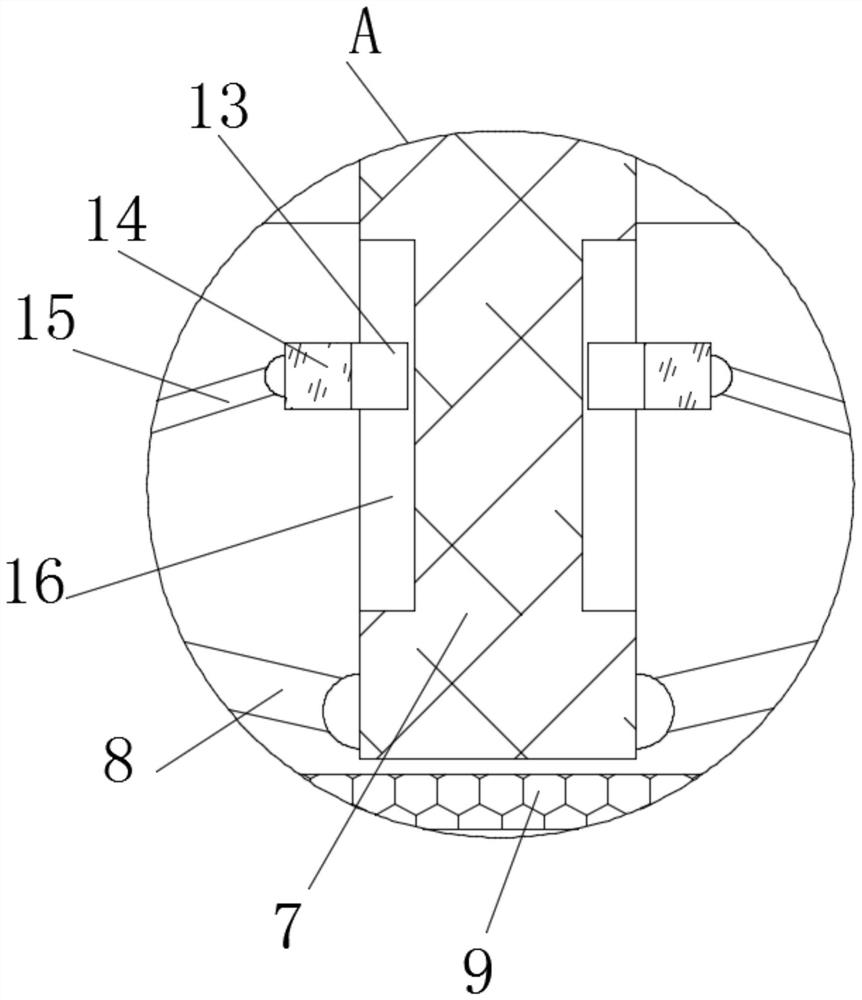

[0038] as Figure 1-5As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the outer wall of the hinge 7 is hinged at the bottom edge of the outer wall of the adjustment rod 8, the outer wall sliding connection of the hinge 7 is connected to the active ring 14, the outer wall of the moving ring 14 is articulated with a connecting rod 15, the other end of the connecting rod 15 is articulated with the outer wall of the adjustment rod 8, the activity ring 14 when sliding, can be adjusted by means of the connecting rod 15 to the angle between the adjustment rod 8 and the shaft 7, the outer wall of the hinge 7 is opened with a slip groove 16, The inner wall sliding connection of the chute 16 is connected to the sliding block 13, the side of the sliding block 13 is fixedly connected to the inner wall of the moving ring 14, the chute 16 can facilitate the sliding block 13, so that the moving ring 14 can slide down steadily.

Embodiment 3

[0040] as Figure 1-5 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the inner wall of the quantitative box 11 is fixed connected to the support frame 32, the top of the support frame 32 is fixed to be connected to the elastic member 29, the top fixed connection to the top of the elastic member 29 is connected to the connecting strip 25, the inner wall side of the connecting strip 25 is fixed connected to the storage hopper 26, the connecting strip 25 and the elastic member 29 are located symmetrically on both sides of the storage hopper 26 symmetrically set, the inner wall of the stock hopper 26 is fixed connected to the support plate 30, The inner wall of the stock hopper 26 is articulated with a flip plate 27, one end of the flip plate 27 is overlapped with the top of the support plate 30, the other end of the flip plate 27 is sliding with the inner wall of the stock hopper 26, the flip plate 27 can be supported by the suppo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap