IGZO (Indium Gallium Zinc Oxide) backboard structure applied to OLED (Organic Light Emitting Diode) panel and manufacturing method

A manufacturing method and backplane technology, applied in the field of OLED display, can solve the problems of large leakage current, low resolution, low electron mobility, etc., and achieve the effects of reducing plane space, reducing pixel area, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

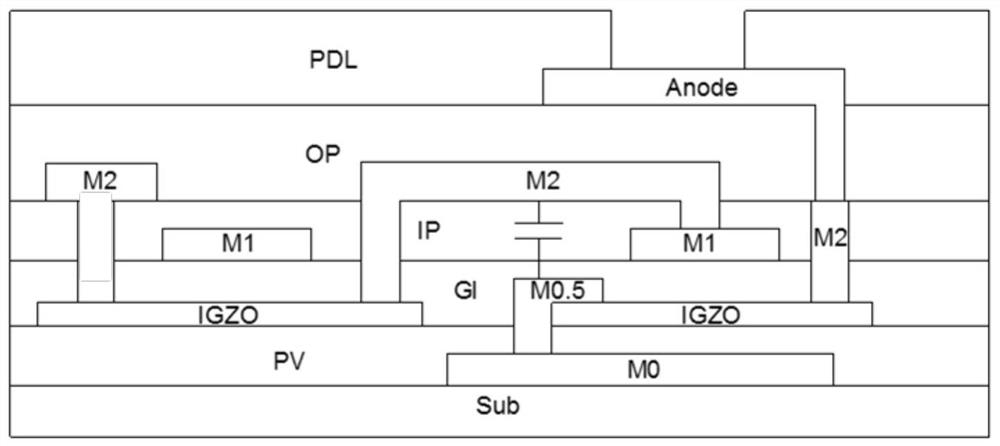

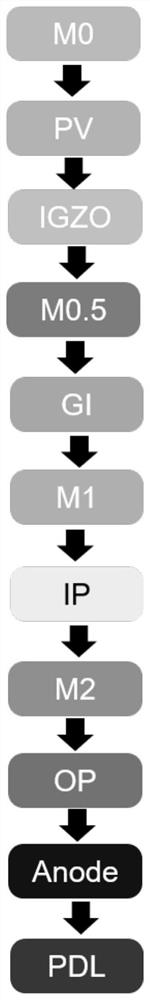

[0040] Please refer to figure 1 , the present invention is an IGZO backplane structure applied to an OLED panel, which includes a substrate Sub;

[0041] A metal layer M0 is provided on the substrate Sub, and the metal layer M0 is used to receive an OVDD signal;

[0042] An insulating layer PV is also provided on the substrate Sub, and the insulating layer PV covers the metal layer M0;

[0043] A semiconductor layer IGZO is disposed on the insulating layer PV;

[0044] A metal layer M0.5 is provided on the IGZO semiconductor layer, and the metal layer M0.5 is connected to the metal layer M0;

[0045] An insulating layer GI is also provided on the insulating layer PV, and the insulating layer GI covers the metal layer M0.5 and the semiconductor layer IGZO;

[0046] A metal layer M1 is disposed on the insulating layer GI, and the metal layer M1 is used for receiving SCAN scanning signals;

[0047] An insulating layer IP is further provided on the insulating layer GI, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com