Flexible driving structure of ultra-large-capacity centrifugal machine

A driving structure and centrifuge technology, which is applied in the direction of centrifuges, can solve the problems of centrifuge production vibration, ineffective repair and maintenance, and spindle deformation, so as to reduce manual debugging time, facilitate assembly and disassembly, and fast. Eliminates the effects of production vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments.

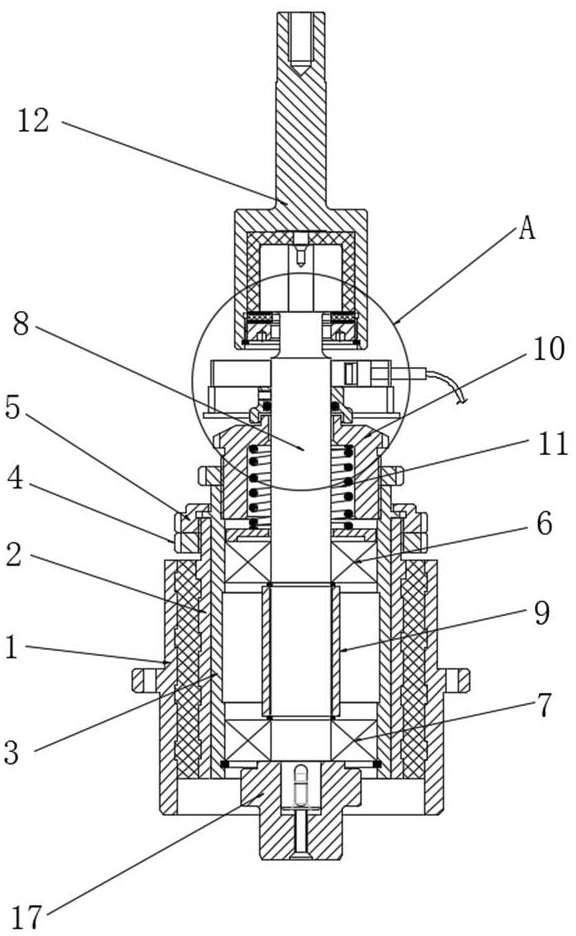

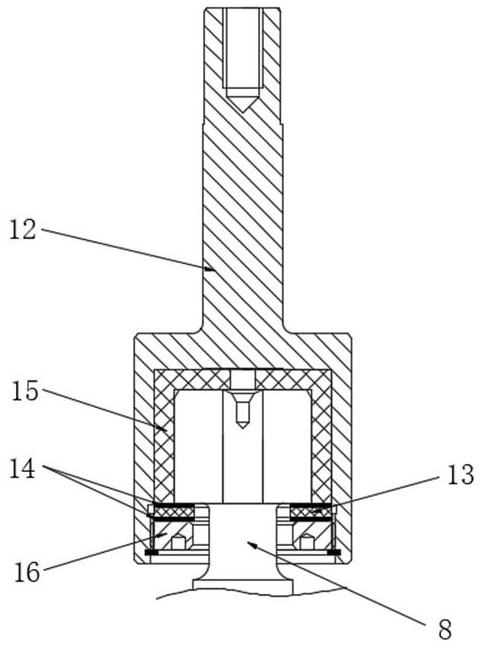

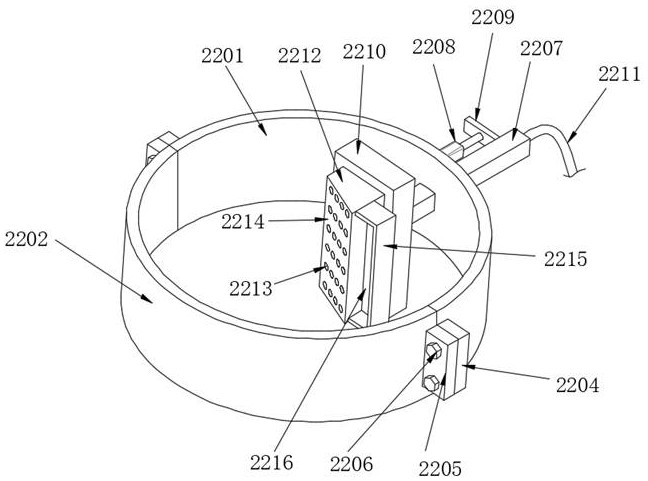

[0028] see figure 1 As shown in the figure, a flexible drive structure of a super-capacity centrifuge includes a drive base 1, a damping seat 2 is arranged in the driving base 1, a bearing seat 3 is arranged in the damping seat 2, and the upper sides of the bearing seat 3 and the damping seat 2 are both A round nut 4 is installed, a gland nut 5 is arranged on the round nut 4, an upper bearing 6 and a lower bearing 7 are installed in the bearing seat 3, a main shaft 8 is installed in the bearing seat 3, and the main shaft 8 penetrates the upper bearing 6 and the lower bearing 7 There is a bearing top sleeve 9 between the upper bearing 6 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com