Abnormal sound monitoring method and system for mechanical equipment

A technology of mechanical equipment and monitoring system, applied in the field of equipment detection, can solve problems such as the inability to effectively identify the existence of abnormal noise, difficulty in fault diagnosis, affecting the operation safety, stability, reliability and load rate of nuclear power plant units, etc. Reduce unplanned outages and avoid the effect of normal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

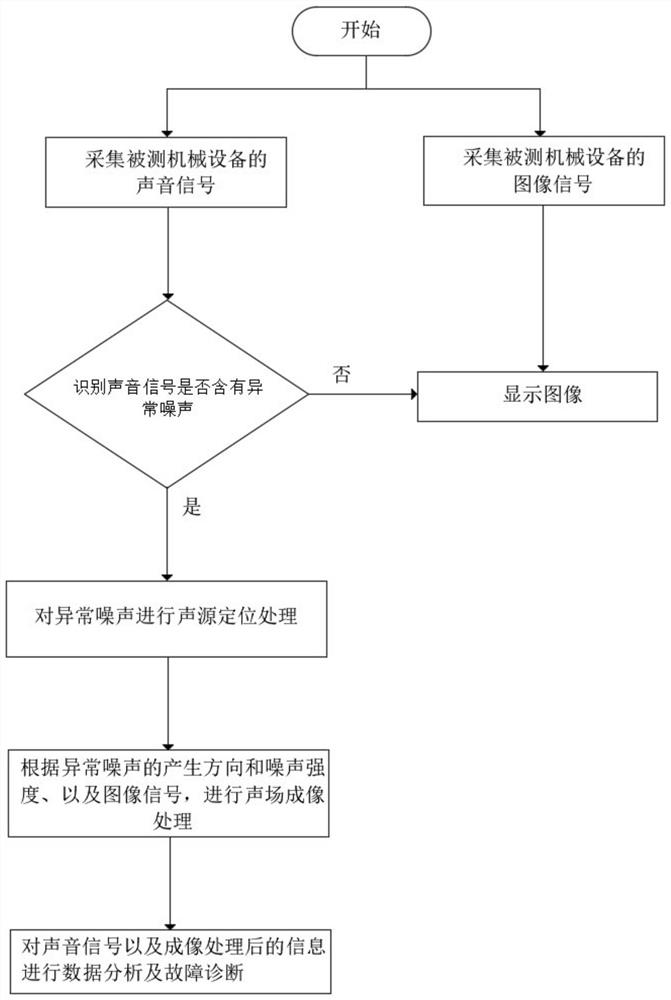

[0044] figure 1 It is the first embodiment of the abnormal sound monitoring method for mechanical equipment provided by the present invention. like figure 1 As shown, the present invention constructs a method for monitoring abnormal sound of mechanical equipment, including step S1, step S2, step S3, step S4 and step S5.

[0045] S1: Collect the sound signal and image signal of the mechanical equipment under test.

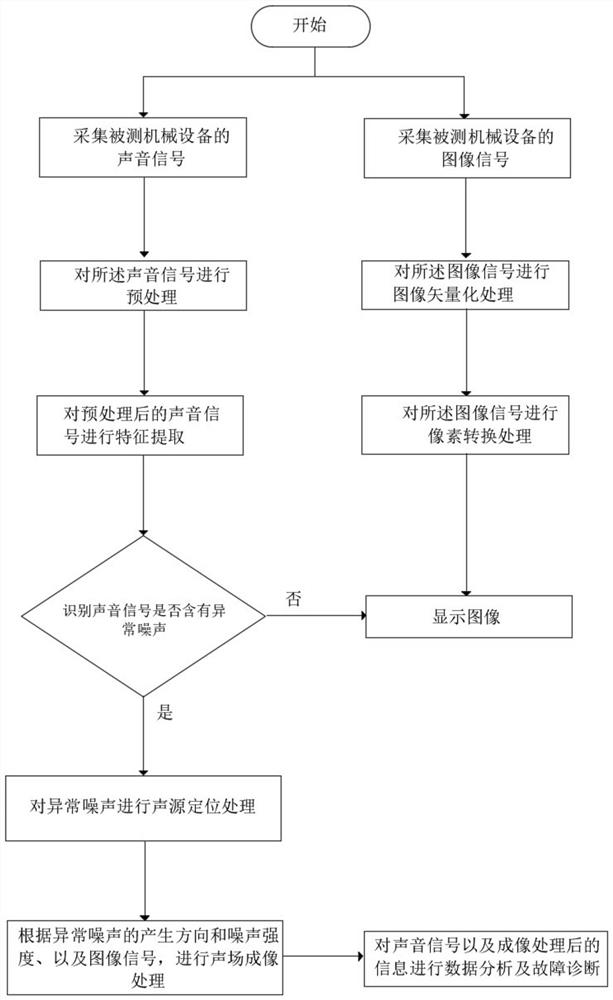

[0046] figure 2 This is a flow chart of the second embodiment of the abnormal sound monitoring method for mechanical equipment provided by the present invention. Compared with the first embodiment, the difference is that step S1 further includes step S11 and step S12.

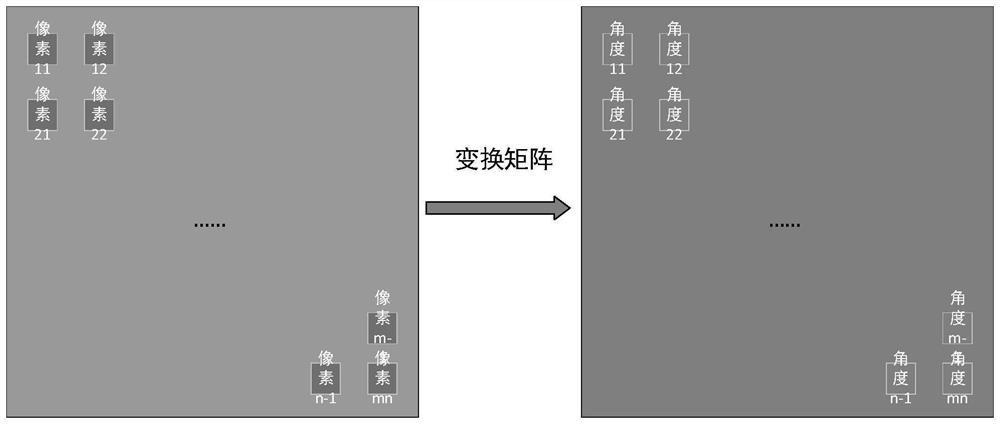

[0047] S11: Pre-processing the sound signal, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com