Probe tool automatic design method, system and device and storage medium

An automatic design and probe technology, applied in the manufacture of computing systems, measuring devices, components of electrical measuring instruments, etc., can solve the problems of cumbersome and time-consuming operations, and achieve the effect of simplifying the operation logic and shortening the cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

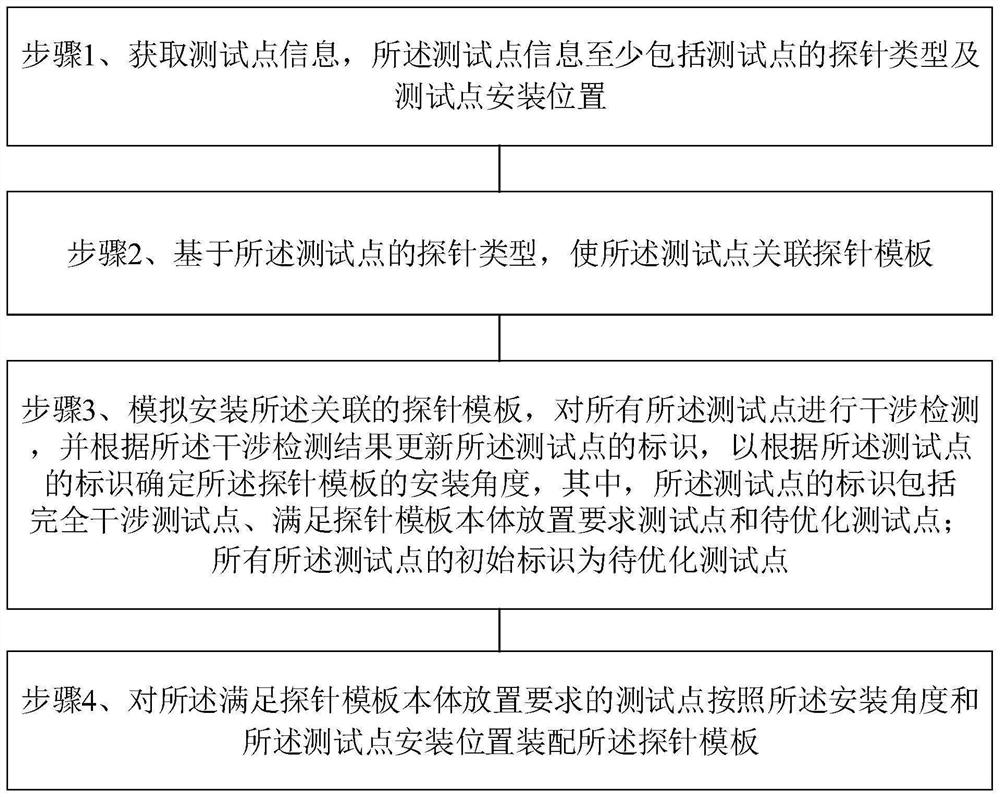

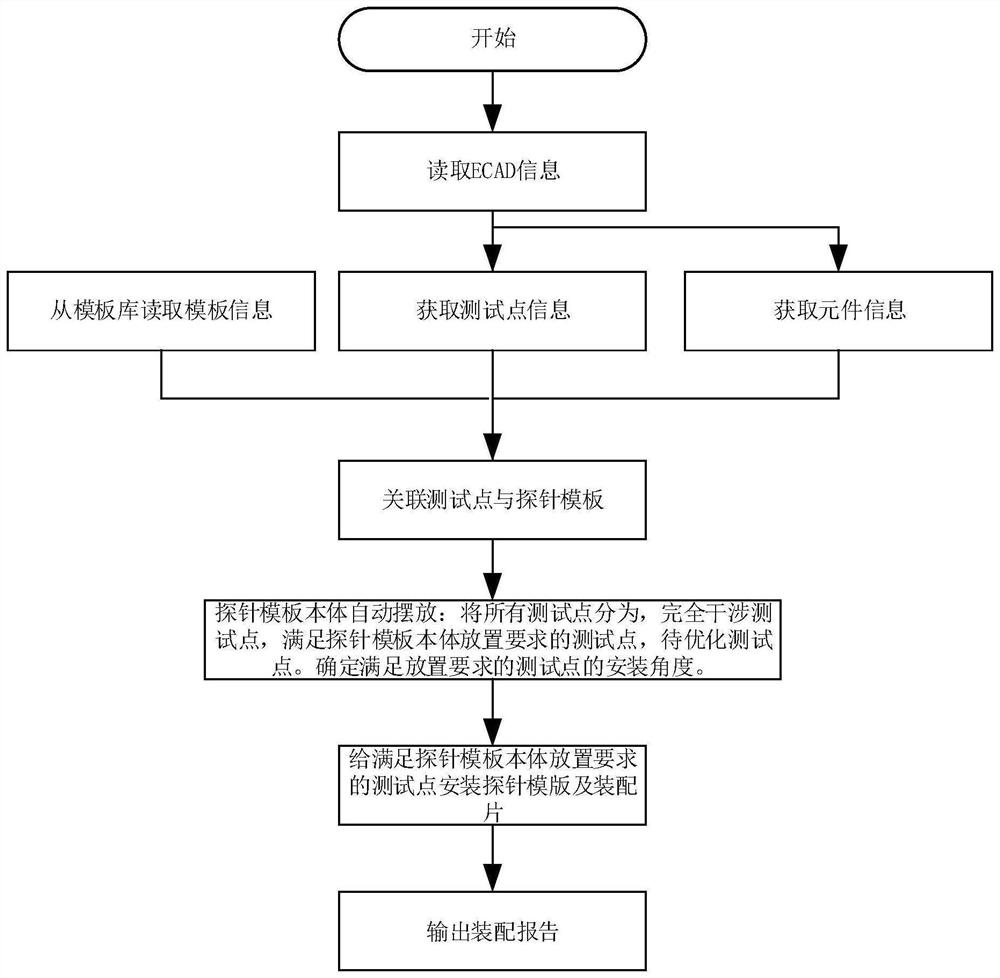

[0043] See figure 1 and figure 2 , figure 1 is a schematic flowchart of a method for automatic design of probe tooling provided by an embodiment of the present invention, figure 2 It is a schematic flowchart of another method for automatic design of probe tooling provided by the embodiment of the present invention. This embodiment provides a method for automatic design of probe tooling, and the method may include steps 1 to 6, wherein:

[0044] Step 1. Obtain test point information, where the test point information at least includes the probe type of the test point and the installation position of the test point.

[0045] (1) Obtain test point information according to the read ECAD data. The test point information includes:

[0046] a. Test point probe types: RF (radio frequency probe), BTB (connector test seat), TP (test point), CA (connector) and LED;

[0047] b. The attributes of the front and back of the test point: Group (when Group=0, the front side; when Group=1, ...

Embodiment 2

[0136] This embodiment further provides a specific method for automatic design of probe tooling on the basis of the above-mentioned embodiment, and the method includes:

[0137] 1. Obtain test point information.

[0138] The mounting surfaces of test points P0, P1, P2, P3, P4, P5, P6, P7, and P8 are BOTTOM surfaces, so the attributes of the front and back of the test points are: Group=1;

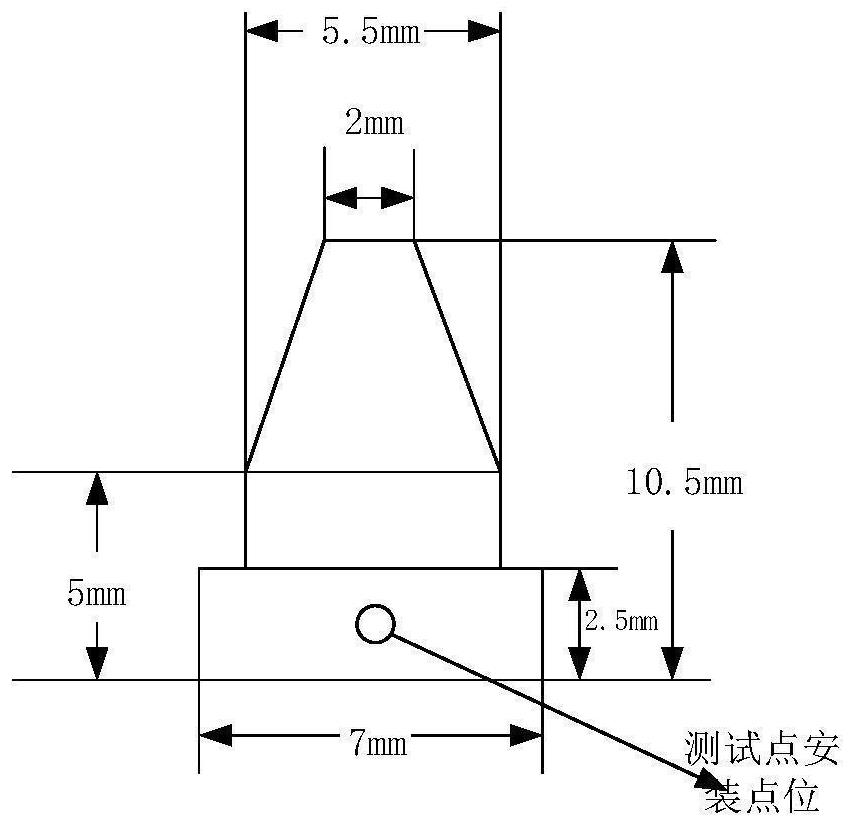

[0139] The probe types of test points P0, P1, P2, P3, P5, P6, and P7 are all RF, the body flag type is 1, and the rotatable type; the test point names (bit numbers) are: P0: RN800, P1: RN801, P2: RN802, P3: RN803, P5: RN805, P6: RN806, P7: RN807;

[0140] The installation positions of the test points are: ((P0(10,30), P1(10,27), P2(12,25), P3(18,20), P5(28,15), P6(43,20) ,P7(50,20));

[0141] The probe type of the test point P4 is BTB; the body mark bit type is 2, which cannot be rotated; the test point installation position is P4 (25,25), and the test point name (bit number) is Q1205;

...

Embodiment 3

[0180] See Figure 14 , Figure 14 It is a schematic diagram of a system for automatic design of probe tooling provided by an embodiment of the present invention. The system for the automatic design of the probe tooling includes:

[0181] an acquisition module for acquiring test point information, where the test point information at least includes the probe type of the test point and the installation position of the test point;

[0182] an association module, configured to associate the test point with a probe template based on the probe type of the test point;

[0183] The installation angle determination module simulates the installation of the associated probe template for performing interference detection on all the test points, and updates the identification of the test point according to the interference detection result, so as to determine the probe template according to the identification of the test point installation angle, wherein, the identification of the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com