Design method of built-in paddle column tuned liquid damper

A technology for tuning liquid damping and design methods, applied in design optimization/simulation, computer-aided design, instruments, etc., can solve problems such as high cost, difficult structure vibration reduction effect, inability to accurately evaluate TLD control effect, etc., to reduce costs , design and apply precise and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

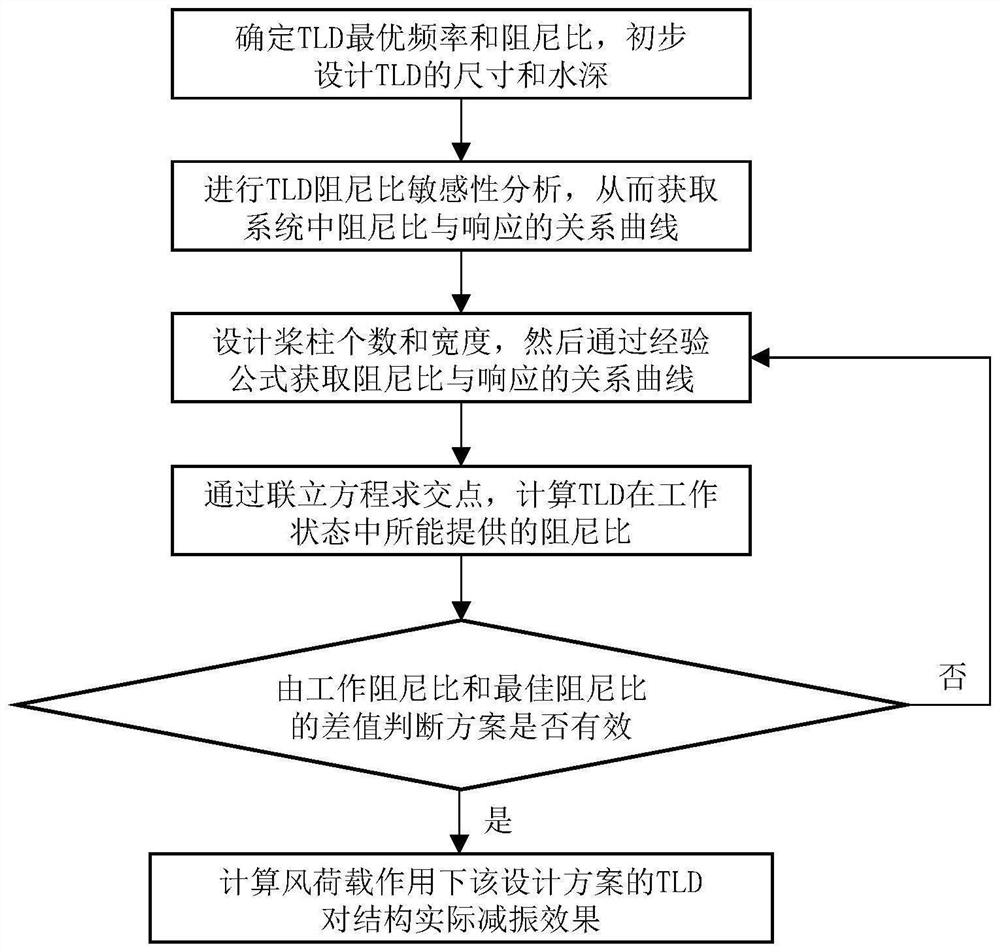

[0073] like figure 1 As shown, the present invention, a design method of a built-in paddle column tuning liquid damper, includes the following steps:

[0074] S1. Determine the optimal sloshing frequency and damping ratio of the TLD through the mass ratio of the controlled structure and the TLD system, and preliminarily design the size and water depth of the TLD; specifically:

[0075] Design a reasonable structure-TLD system mass ratio according to the requirements of the project, and then calculate the shaking frequency f when the TLD achieves the optimal control effect T and damping ratio ζ T , the specific formula is:

[0076]

[0077]

[0078] where f S is the natural frequency of the structure. Investigate the plane shape of the floor where the TLD is located and design an appropriate length L, and then calculate the water depth h from the theoretical formula of the fundamental frequency of the rectangular TLD. The specific formula is:

[0079]

[0080] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com