A test method for valve flow characteristics of steam turbine units in constant power mode

A technology for flow characteristics and steam turbine units, which is applied in engine testing, machine/structural component testing, and mechanical equipment. Efficiency and test quality, the effect of reducing systematic and random errors, and reducing the safety risk of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

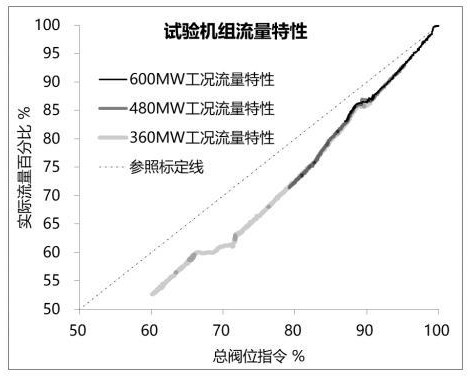

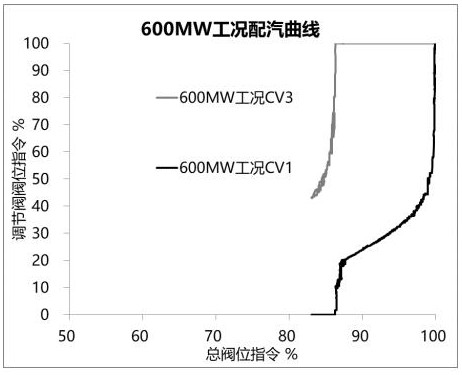

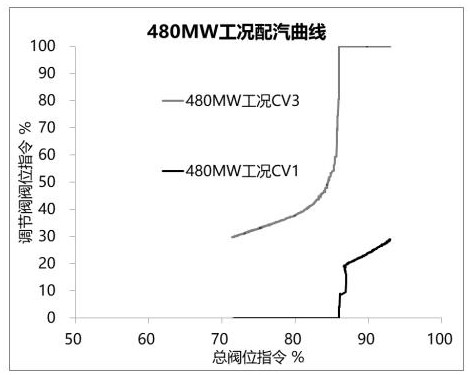

[0027] The specific embodiment of the present invention is shown in the figure. The following will be combined with the appendix in the embodiment of the present invention Figure 1-4, to clearly and completely describe the technical solutions in the embodiments of the present invention.

[0028] The unit in this embodiment is an ultra-supercritical 660MW steam turbine unit, and in the sequence valve mode, the valve opening sequence is GV2 / 4 (synchronized)→CV3→CV1.

[0029] The test method for the valve flow characteristic of the steam turbine unit in the constant power mode of the present embodiment includes the following steps:

[0030] (1) According to the manufacturer's instructions and on-site actuality, select high, medium and low load conditions such as 90% nameplate power, 70% nameplate power and 50% nameplate power as test conditions; The feasible sliding pressure interval is determined, and the corresponding feasible valve position interval is determined; it is ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com