Method for testing flow characteristics of control valve of turboset in constant power mode

A technology for flow characteristics and steam turbine units, which is applied in engine testing, machine/structural component testing, and mechanical equipment. Errors and random errors, improving test efficiency and test quality, and reducing the effect of misoperation safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

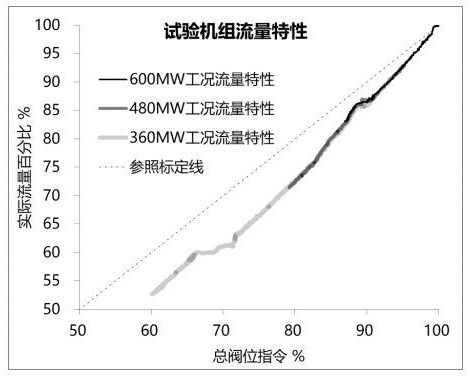

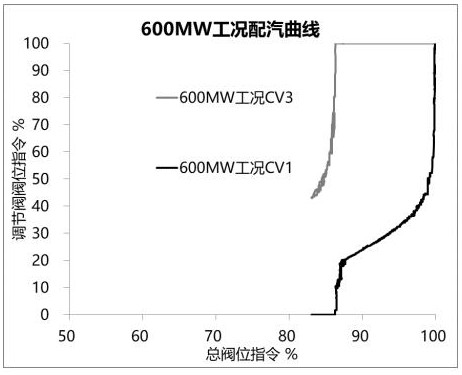

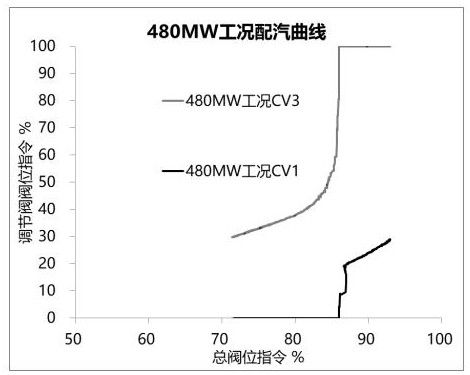

[0027] The specific embodiment of the present invention is shown in the figure. Below will be combined with the appended in the embodiment of the present invention Figure 1-4, clearly and completely describe the technical solutions in the embodiments of the present invention.

[0028] The unit of this embodiment is an ultra-supercritical 660MW steam turbine unit, and in the sequential valve mode, the opening sequence of the regulating valve is GV2 / 4 (synchronous)→CV3→CV1.

[0029] In this embodiment, the test method for the flow characteristics of the steam turbine unit in the constant power mode includes the following steps:

[0030] (1) Select high, medium and low load conditions such as 90% nameplate power, 70% nameplate power and 50% nameplate power as test conditions according to the manufacturer's instructions and on-site actual conditions; Feasible sliding pressure interval, determine the corresponding feasible valve position interval; ensure that the feasible valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com