Direct current screen convenient for dust cleaning

A DC screen and dust technology, applied in the field of DC screen, can solve the problems of heat accumulation, easy adhesion of dust, unfavorable use, etc., to achieve the effect of ensuring ventilation performance, avoiding adhesion dust, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

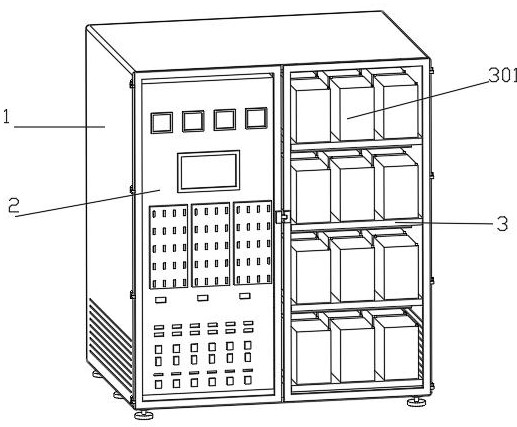

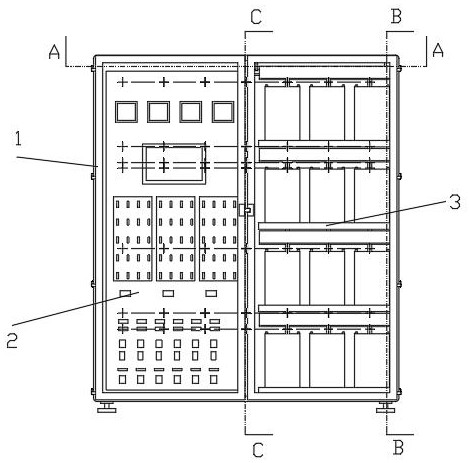

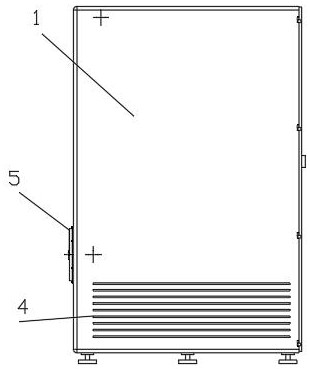

[0043] like Figure 1-13 As shown in the figure, the DC screen is easy to clean the dust, including the DC screen box 1, the DC screen control unit 2 and the battery support plate 3. The lower ends of the two side walls of the DC screen box 1 are evenly opened with air outlets 4, and the DC screen control unit 2 and the battery support plate 3. The battery support plates 3 are respectively arranged on both sides inside the DC panel box 1. The top of the battery support plate 3 is evenly connected with the batteries 301, and the batteries 301 are arranged in a 3*3 array on the top of the battery support plate 3. The DC panel box 1 The rear side wall is provided with an air intake assembly, the air intake assembly is connected with a quick connection assembly, the quick connection assembly is movably connected with a filter screen 7, and the air intake assembly is connected with a dust cleaning assembly, which is movably connected with the filter screen 7, and the air intake The...

Embodiment 2

[0046] On the basis of Example 1, see image 3 , 4 As shown in and 8, the air intake assembly includes an air intake hood 5, an air intake fan 18 and an air intake pipe 19, and an air intake hood 5 is installed in the mounting hole of the rear side wall of the DC screen box 1, and the air outlet end of the air intake hood 5 is connected to the intake air hood 5. The input end of the air fan 18 is fixedly connected, the air intake fan 18 is installed on the inner wall of the DC panel box 1, and the output end of the air intake fan 18 is fixedly connected with an air intake pipe 19.

[0047] The filter screen 7 filters the air, and the air intake fan 18 of the air intake assembly draws clean air into the air intake pipe 19 through the air intake cover 5 to facilitate driving the clean air into the DC screen box 1 .

Embodiment 3

[0049] On the basis of Example 2, see Figure 9 and 12 As shown, the quick-connect assembly includes a limit rod 32 and a fixed outer cover 33, the outer end side wall of the air intake cover 5 is fixed with the limit rod 32 at equal intervals along the circumferential direction, and the outer end of the air intake cover 5 is threadedly connected with a fixed outer cover 33. The net 7 is inserted into the limit rod 32 through the opening hole. When the fixed outer cover 33 and the air intake cover 5 are connected, the fixed outer cover 33 presses the filter screen 7 against the outer end of the air intake cover 5 .

[0050] The filter screen 7 is plugged with the limit rod 32 of the quick-connect assembly, which is convenient for the filter screen 7 to be installed on the limit rod 32. At the same time, the fixed outer cover 33 is threadedly connected with the air intake cover 5, which is convenient for the fixed outer cover 33 to be installed on the air intake cover 5. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com