Coffee pot base and processing method thereof

A processing method and coffee pot technology, which is applied in the field of daily necessities, can solve problems such as unsatisfactory and unusable electric coffee pots, and achieve the effects of changing product density, improving smoothness, and increasing heat conduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

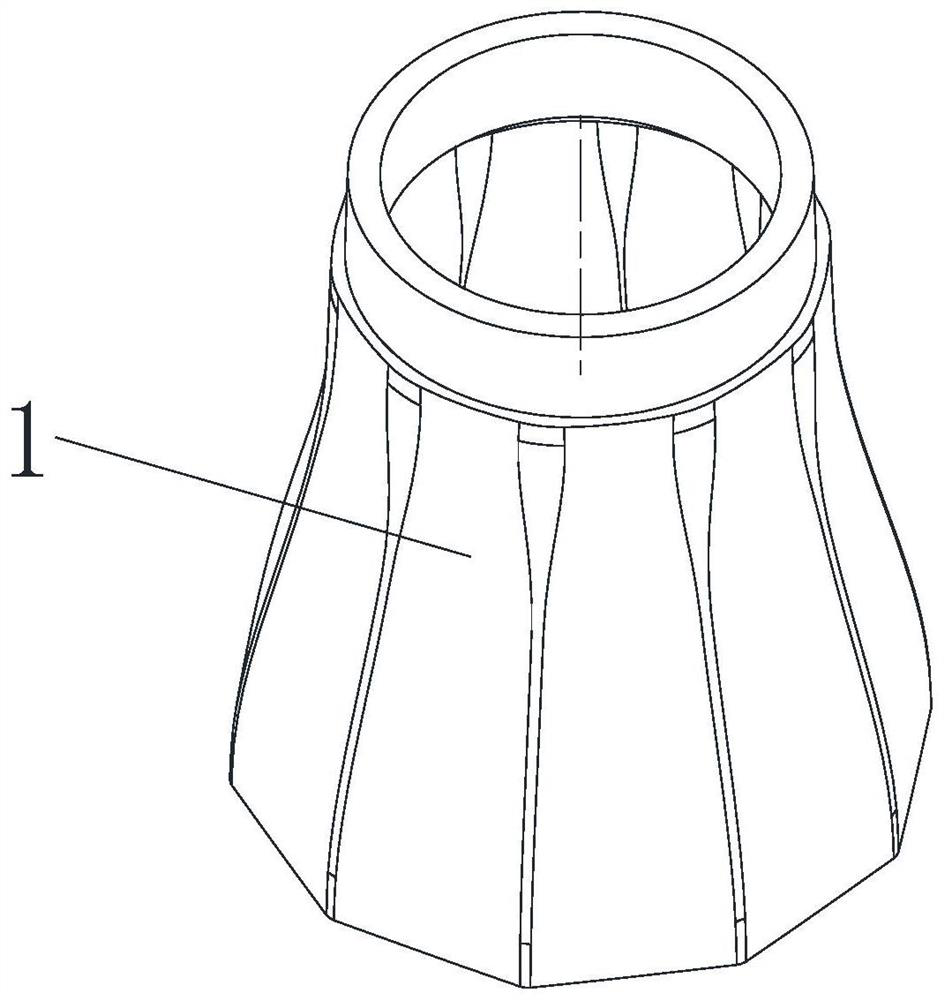

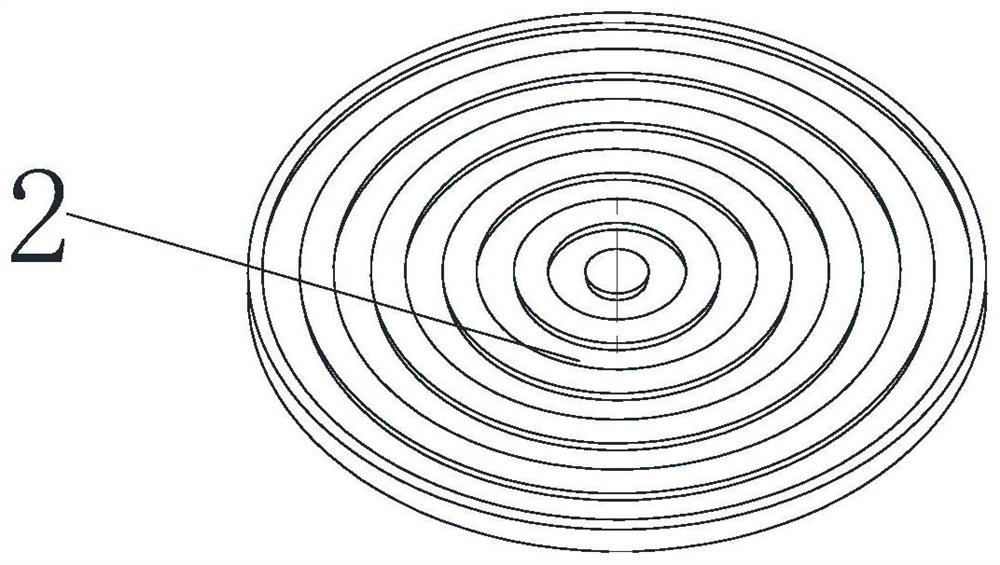

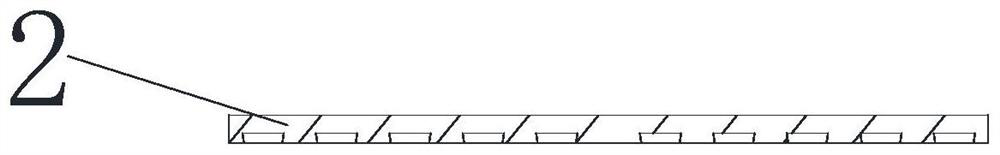

[0026] see Figure 1-3 , This embodiment provides a coffee pot base, including a base body 1, the base body 1 is formed by high pressure die casting; the base body 1 is a trapezoid structure, the bottom is large and the mouth is small, the inner wall of the base body 1 is The structure is consistent with the outer surface structure, and the wall thickness is uniform; the bottom of the base body 1 is a composite aluminum plate 2, and the inner surface of the bottom surface of the composite aluminum plate 2 is evenly distributed with several circles of annular protrusions.

[0027] The base body 1 of the present invention is formed by high pressure die casting, and the product has a higher density, can be used on gas stoves and induction cookers, and conducts heat faster.

Embodiment 2

[0029] This embodiment provides a method for processing a coffee pot base described in Embodiment 1, and the specific steps are as follows:

[0030] S1, place the raw material aluminum ingot in a melting furnace to heat up to 710 degrees, and turn the aluminum ingot into aluminum water for use;

[0031] S2, put the inner inserts into the movable mold of the die-casting machine after assembling, install the composite aluminum plate on the fixed mold of the die-casting machine, and close the movable mold and the fixed mold;

[0032] S3, the aluminum water in step S1 is added to the die-casting machine, and the die-casting machine performs high-pressure die-casting of the coffee pot base,

[0033] In step S4, the mold is opened and the parts are taken out, and the formed base of the coffee pot is taken out, and the inner insert is taken out.

[0034] In step S4 of this embodiment, after the mold is opened and the parts are taken out, it is necessary to spray and blow the formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com