Scalpel grinding machine

A scalpel and grinding machine technology, which is applied in the direction of grinding machine tool parts, grinding machines, grinding drive devices, etc., can solve the problems of low grinding precision, grinding asymmetry, and large processing deviation of scalpels, etc., to achieve improved grinding Accuracy, reduced vibration, large deviation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

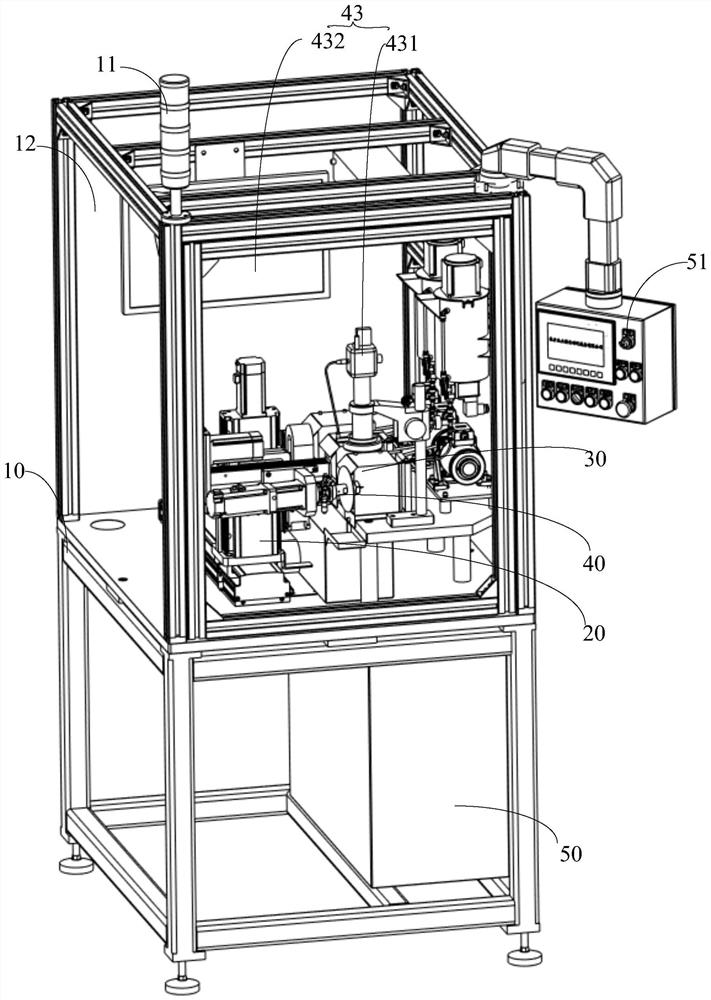

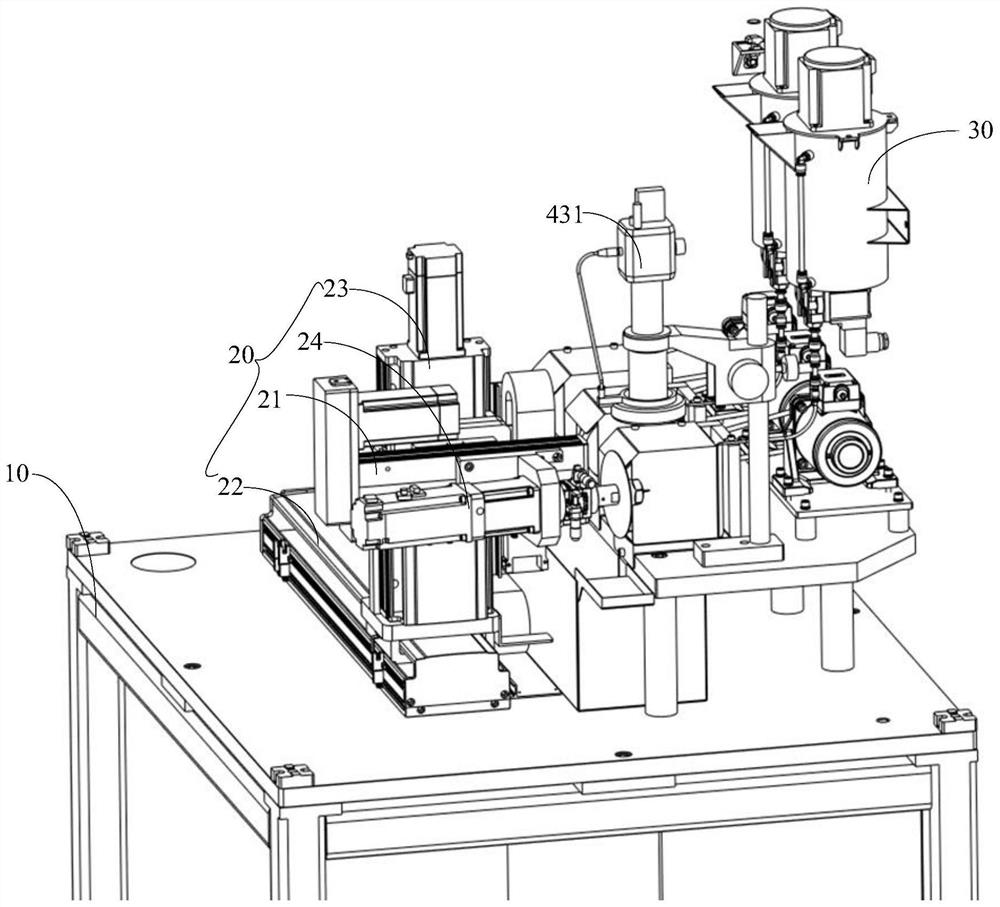

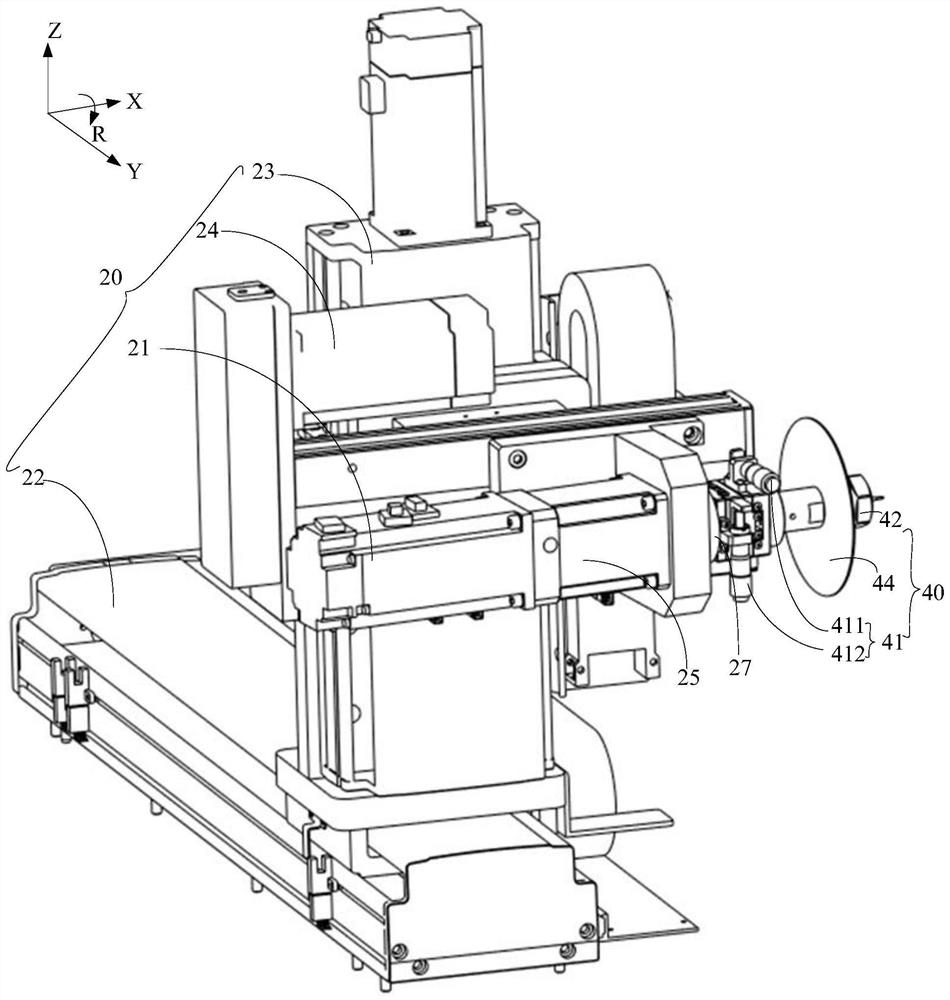

[0037] refer to Figure 1 to Figure 9 , the present invention provides a scalpel grinder. The scalpel 60 needs to process four blade surfaces and blade tips, and needs to meet the tolerances of blade thickness and blade symmetry. The surgical grinder includes: a frame 10, a feeding device 20, a grinding disc device 30 and a clamping device 40, the frame 10 is used to provide a fixed installation position, the frame 10 includes a bottom frame and is arranged on the frame The surrounding transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com