Winding and spraying integrated manufacturing device for hydrogen storage cylinder made of carbon fiber winding composite material

A technology for winding composite materials and manufacturing devices, which is used in manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of difficult to control the ratio of resin to carbon fiber, resin take-out, resin waste, etc. Resin dripping and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, and the purpose and effects of the present invention will become clearer.

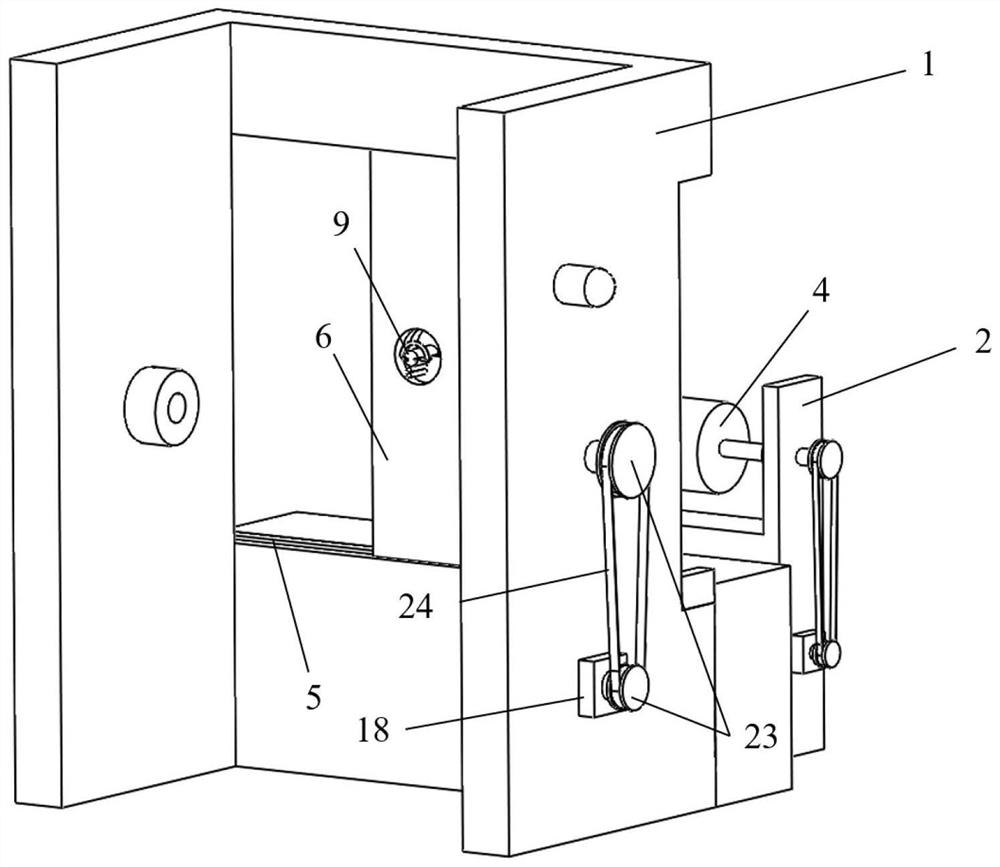

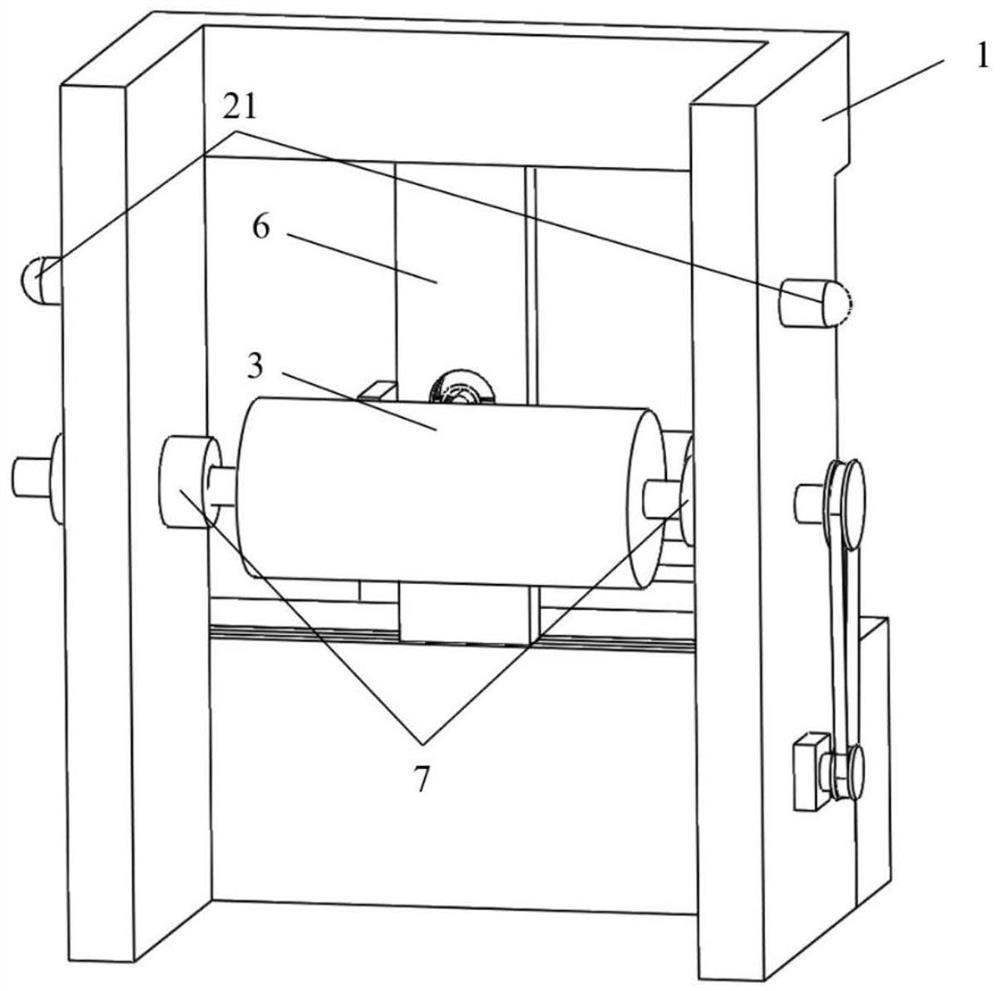

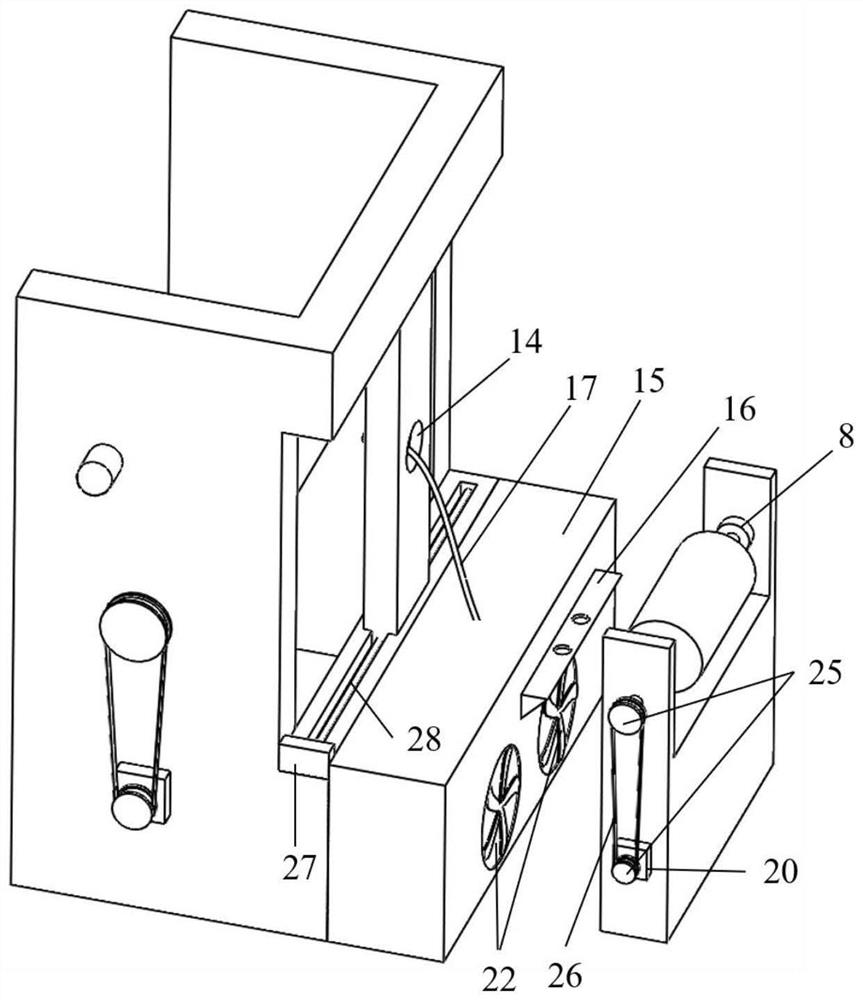

[0032] like figure 1 and 2 As shown, the carbon fiber winding composite hydrogen storage bottle winding and spraying integrated manufacturing device of the present invention uses a high-precision nozzle module, which is combined with a series of modules such as a positioning module and a heating module. During the wrapping and spraying operation, the heating module collects the temperature information of the resin in the dipping device and controls the temperature of the resin within a suitable temperature range; the extrusion mechanism sends the resin to the nozzle module and controls the flow rate of the resin sprayed out ; The FDM nozzle on the nozzle module sprays resin on the junction of the carbon fiber filament and the bottle core, and the position sensor on the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com