Damping shock absorber

A shock absorber and damping technology, applied in the field of damping shock absorbers, can solve the problem of a single shock absorption direction of the damping shock absorber, and achieve the effects of increasing energy consumption, convenient processing, and increasing energy consumption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

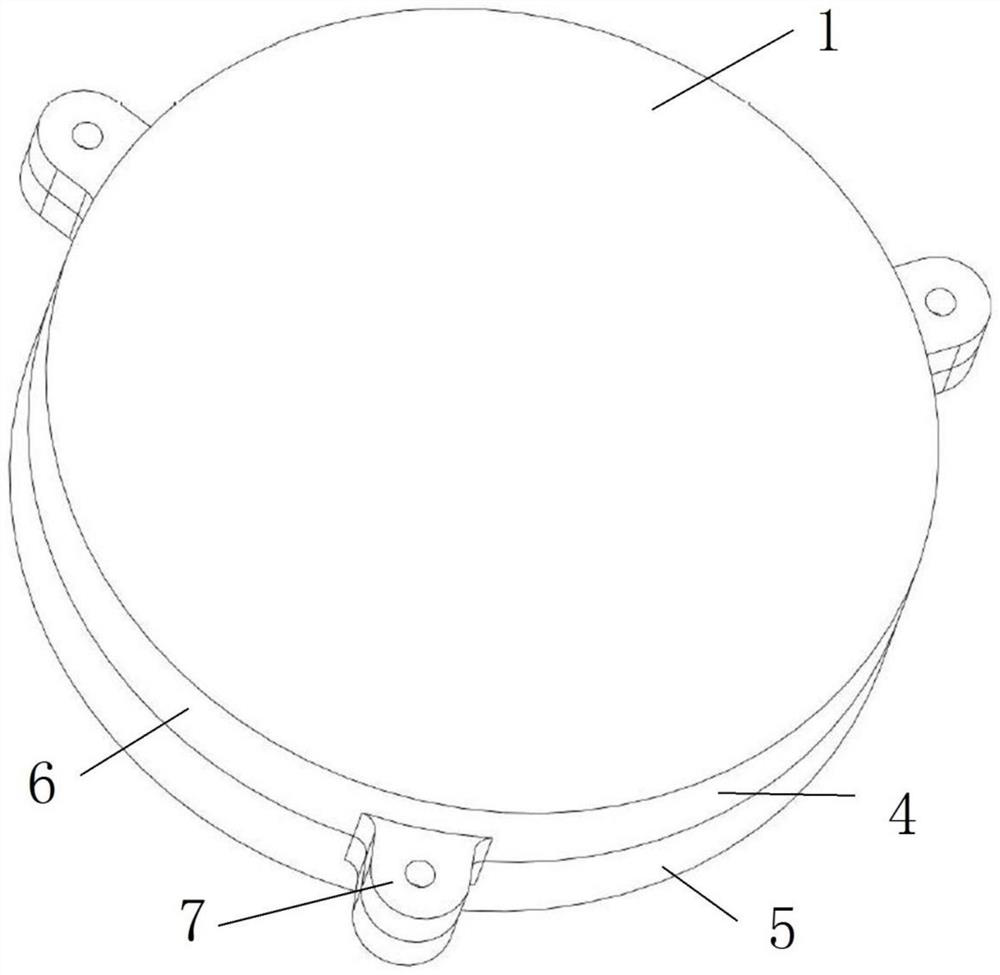

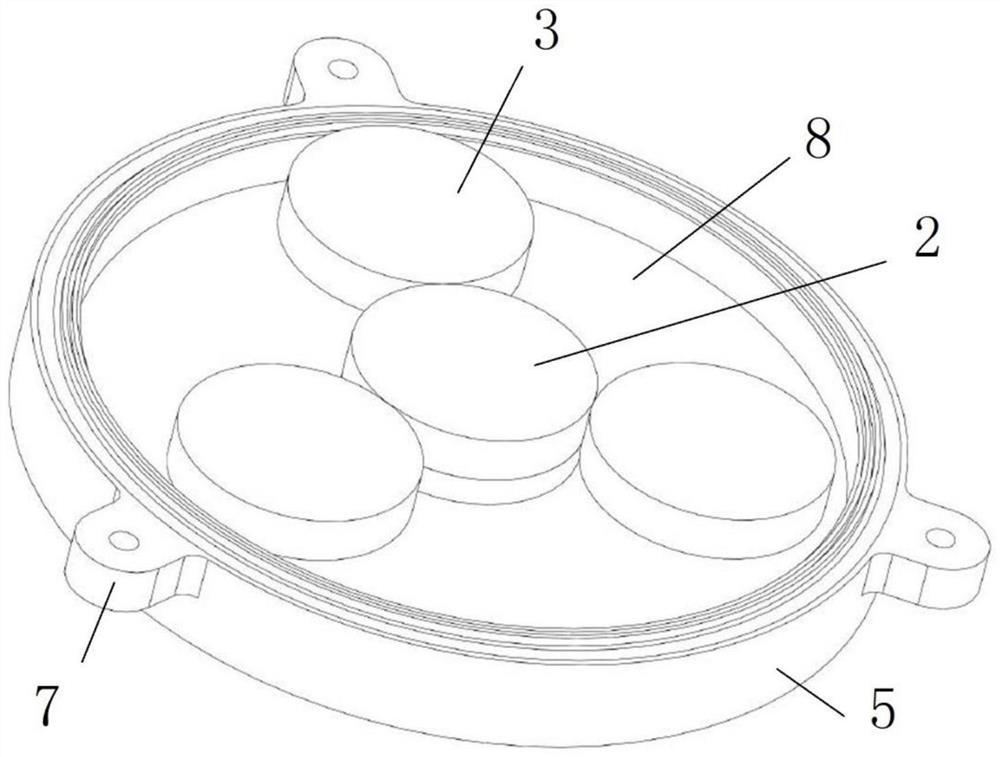

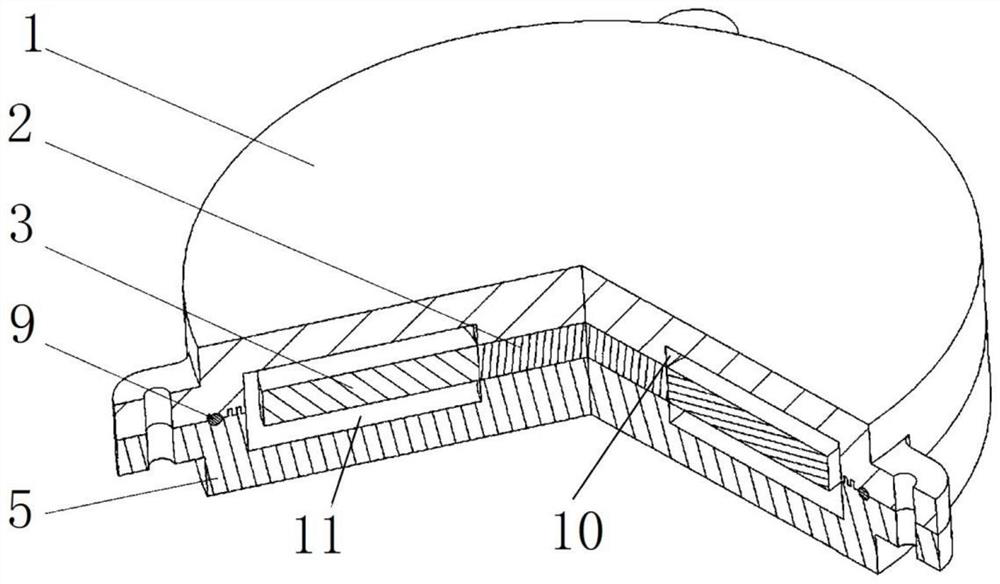

[0039] like Figure 1 to Figure 3 As shown, the shock absorber includes a housing 1 , a fixed permanent magnet 2 and an energy dissipation permanent magnet 3 .

[0040] The housing 1 is a non-magnetically conductive housing made of a non-magnetically conductive material. The housing 1 includes a first housing 4 and a second housing 5. Both the first housing 4 and the second housing 5 include a circular main housing 6 And the connecting lugs 7 arranged around the outer circumferential surface of the main casing 6, there are three connecting lugs 7 on the main casing 6 and are arranged at equal intervals, and the bolt holes for the fastening bolts to pass through are provided on the connecting lugs 7. After the fixing bolts pass through the bolt holes on the corresponding connecting ears 7 on the first shell 4 and the second shell 5 , the nuts are then screwed to realize the fast connection of the first shell 4 and the second shell 5 . The first casing 4 and the second casing 5...

Embodiment 8

[0054] Embodiment 8 of the damping shock absorber of the present invention is different from Embodiment 1 in that the three energy-consuming permanent magnets in Embodiment 1 constitute an energy-consuming permanent magnet group. In this embodiment, the energy-consuming permanent magnets are There are two sets of energy-consuming permanent magnets, and the two sets of energy-consuming permanent magnets are arranged at intervals in the axial direction of the fixed permanent magnets. Or in other embodiments, there are three, four or more energy-dissipating permanent magnet groups, and the energy-dissipating permanent magnet groups are arranged at intervals in the axial direction of the fixed permanent magnets.

[0055] Embodiment 9 of the damping shock absorber of the present invention is different from Embodiment 1 in that, as Figure 4 As shown, the outer circumferential surfaces of the fixed permanent magnet 2 and the energy-consuming permanent magnet 3 are provided with a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com