Fireproof check exhaust valve

A technology for exhaust valves and check plates, which can be used in valve devices, control valves, safety valves, etc., and can solve problems such as failure of elastic force, loss of barriers to fire and fire spread, failure of return plates to reset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

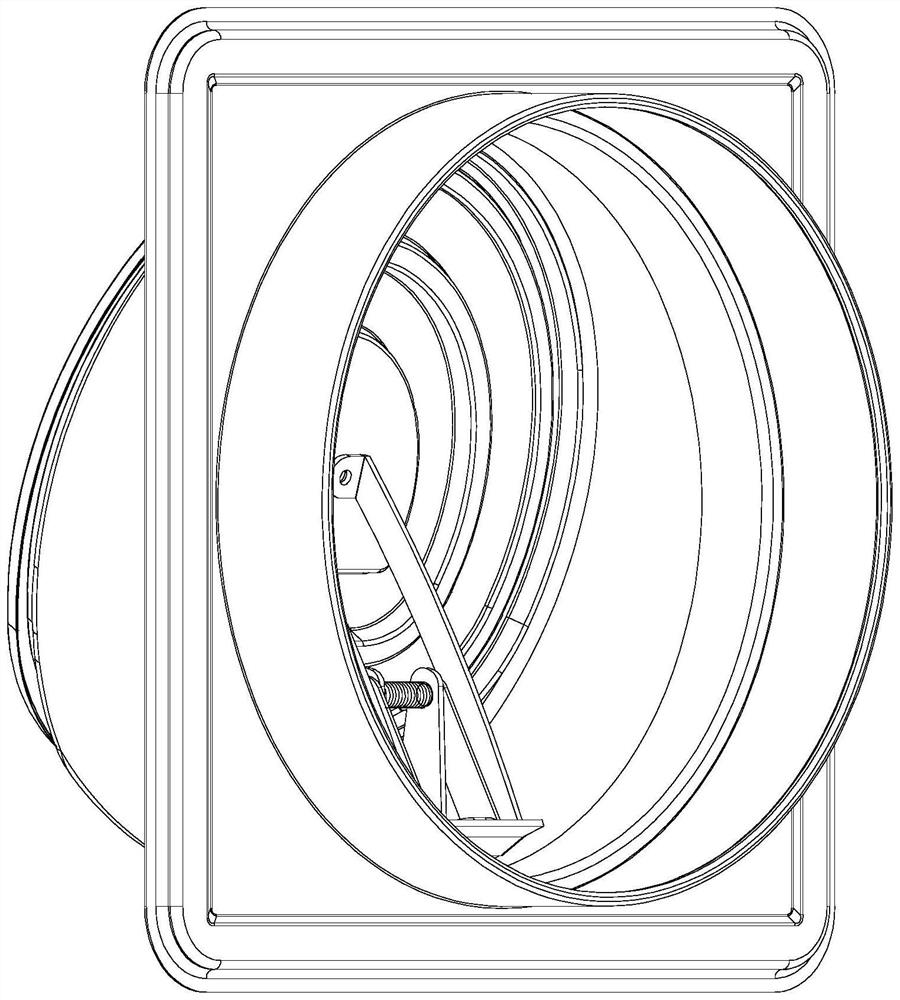

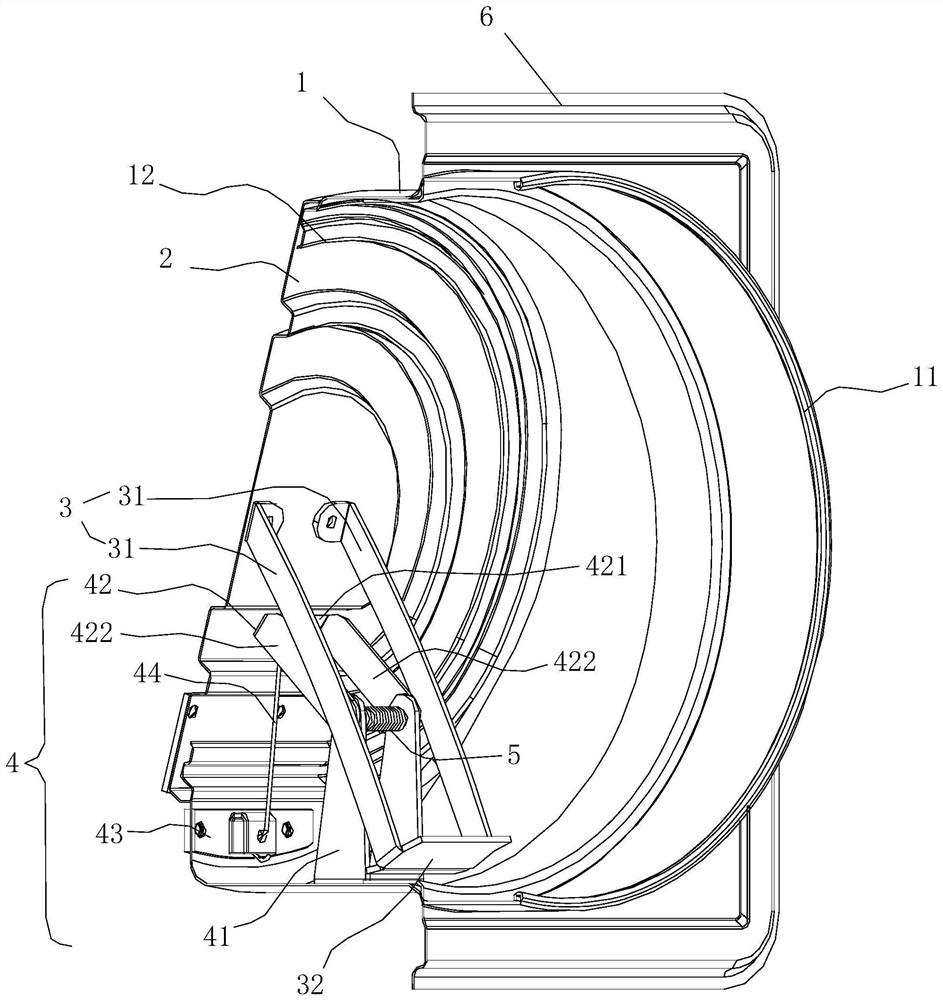

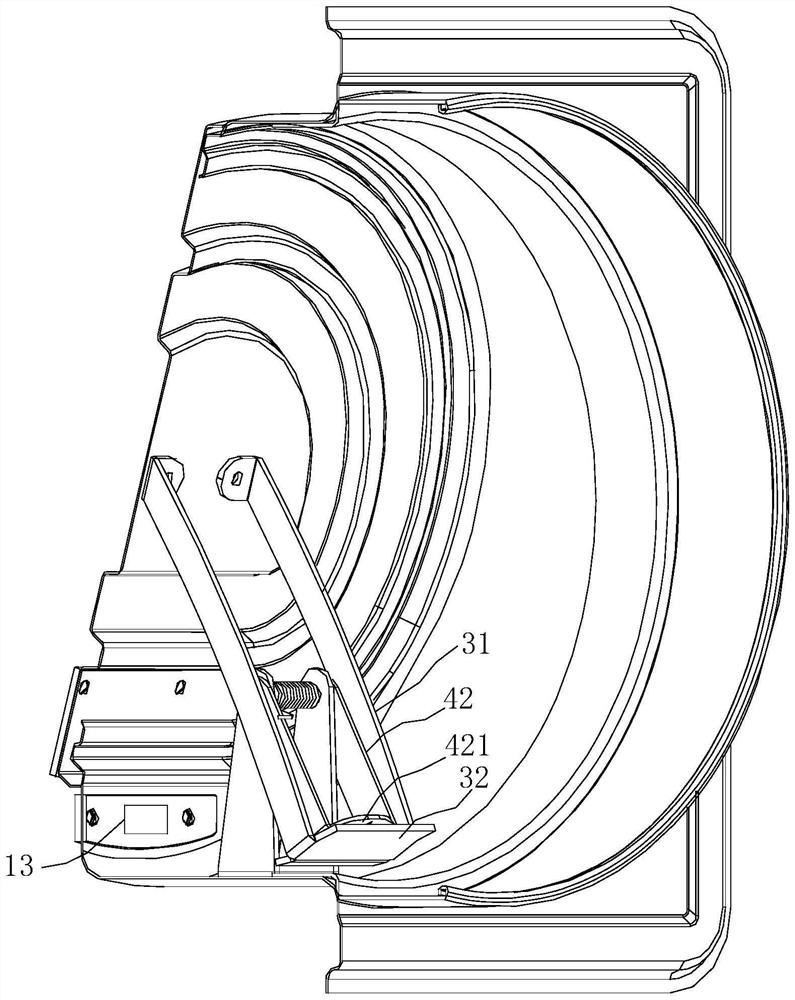

[0029] like figure 1 , figure 2 and image 3 As shown, the present invention discloses a fireproof check exhaust valve, comprising a main body 1, the main body 1 is provided with an air inlet 11 and an air outlet 12, and the air outlet 12 is provided with a check that can close the air outlet 12 Plate 2, one end of the non-return plate 2 is hinged with the body 1 to realize automatic return when there is no wind flow. There is also a locking mechanism 4 inside. The locking mechanism 4 includes a base 41, a locking member 42, and a fuse 43. The base 41 is fixed in the body 1, and the locking member 42 is rotatably arranged on the base 41. The locking member A torsion spring 5 is arranged between 42 and the base 41, a pull rod 44 connected to the locking member 42 is arranged on the fuse 43, a locking plate 421 and a swing arm 422 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com