High-voltage power distribution unit for vehicle-mounted composite power supply and control method of high-voltage power distribution unit

A high-voltage power distribution and composite power supply technology, which is applied in the direction of electrical components, vehicle components, circuit devices, etc., can solve the problems that cannot meet the long-term leakage current and over-discharge protection of vehicles, and cannot satisfy the single or parallel coupling of the power system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

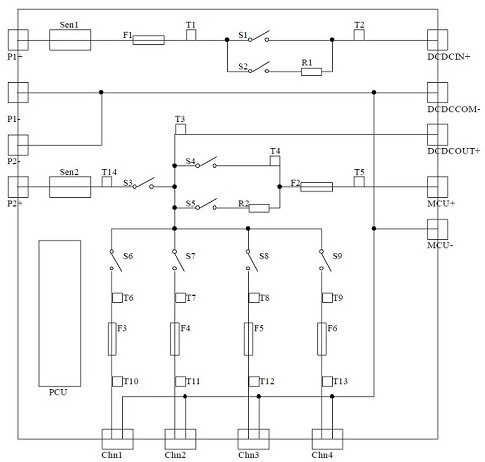

[0067] figure 1 It is an electrical schematic diagram of a high-voltage power distribution unit of a vehicle-mounted composite power supply provided in Embodiment 1 of the present invention, such as figure 1 As shown, a high-voltage power distribution unit for vehicle composite power supply includes high-voltage connectors P1+, P1-, P2+, P2-, DCDCIN+, DCDCOUT+, DCDCCOM-, MCU+, MCU-, Chn1, Chn2, Chn3, Chn4, current sensor Sen1, Sen2, fuses F1, F2, F3, F4, F5, F6, contactors S1, S2, S3, S4, S5, S6, S7, S8, S9, pre-charging resistors R1, R2, high voltage controller PCU, Sampling points T1, T2, T3, T4, T5, T6, T7, T8, T9, T10, T11, T12, T13, T14, high-voltage copper bars, and shell assemblies;

[0068] The high-voltage connectors P1+ and P1- are respectively connected with the positive and negative poles of the first power supply of the composite power supply system; the high-voltage connectors P2+ and P2- are respectively connected with the positive and negative poles of the se...

Embodiment 2

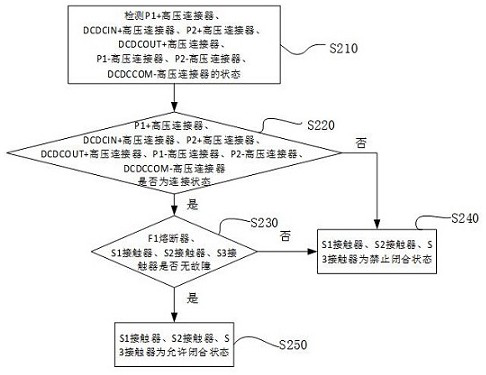

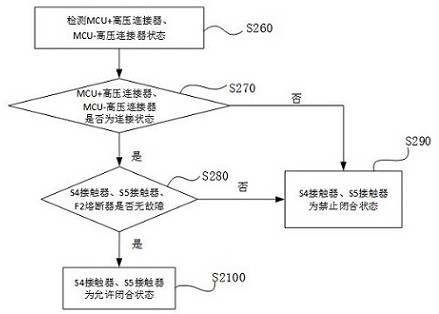

[0096] figure 2 This is a flowchart of a connector detection program in a method for controlling a high-voltage power distribution unit of a vehicle-mounted composite power supply provided in the second embodiment of the present invention. Through the connector state detection, real-time state and fault state reporting is realized, and at the same time, the loop contactor is allowed to close state judgment. .

[0097] The connection status of the high-voltage connector is judged by the high-voltage connector status feedback signal. When the high-voltage connector connection feedback signal is in the disconnected state, the corresponding connector disconnection fault is reported, and the connector at the front or rear of the connector is disconnected at the same time.

[0098] like Figure 2~Figure 7 As shown, the technical solution of the embodiment of the present invention specifically includes the following steps:

[0099] S210. Detect the states of the high-voltage conne...

Embodiment 3

[0130] Figure 8~Figure 13 This is a flowchart of an insulation detection procedure in a method for controlling a high-voltage power distribution unit of a vehicle-mounted composite power supply provided by the third embodiment of the present invention. The insulation resistance value of the casing is detected by sampling points to realize the inspection of the insulation status of each circuit and the reporting of insulation faults, and at the same time, the judgment of the allowable closed state of the circuit contactor is realized.

[0131] By detecting the insulation resistance value between each sampling point and the casing, the insulation state of the circuit where the sampling point is located is judged. When the insulation resistance of a sampling point is lower than the set threshold, the corresponding circuit insulation fault is reported, and the circuit where the sampling point is located is disconnected at the same time. contactor.

[0132] like image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com