Defoaming type semiconductor chip packaging device

A packaging device and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of cracking of epoxy resin layer, poor protection effect of electronic components, etc., and achieve the effect of improving the defoaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

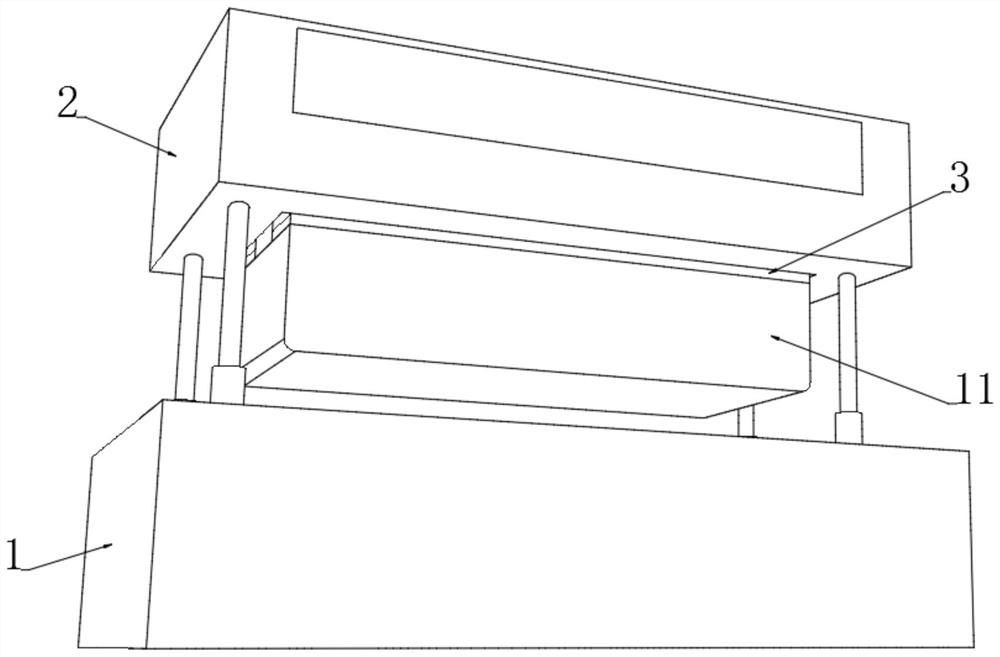

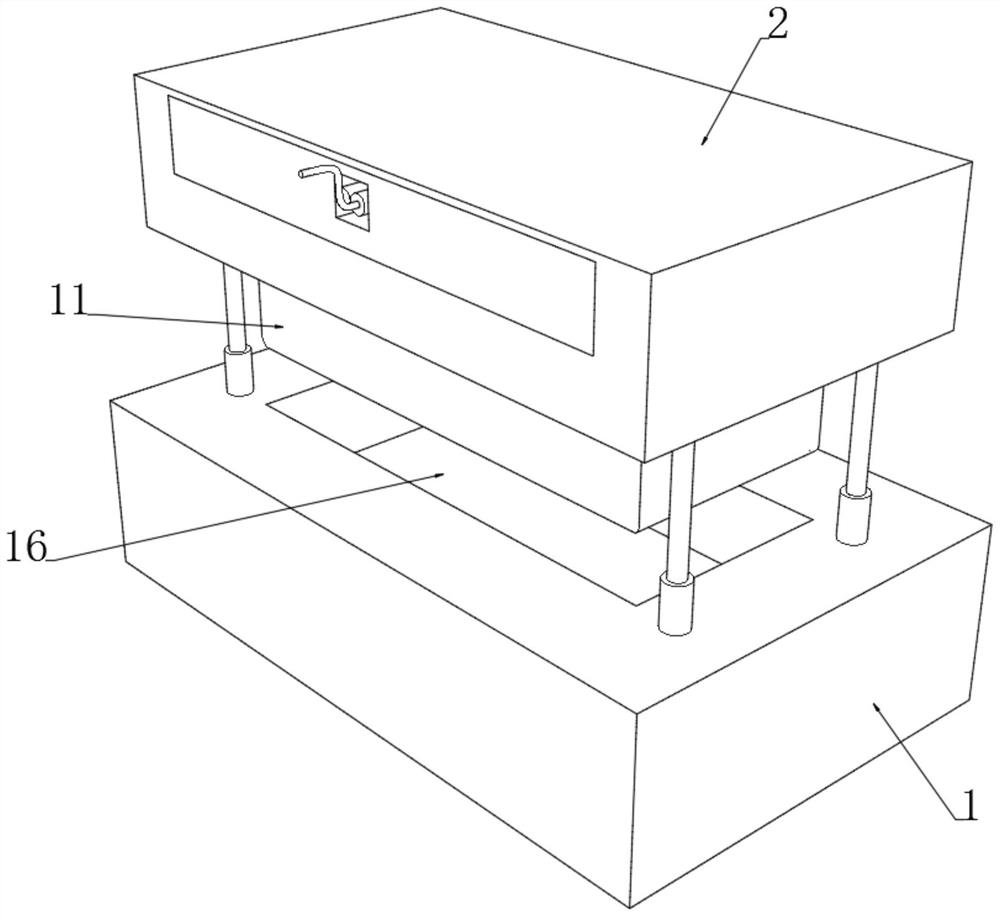

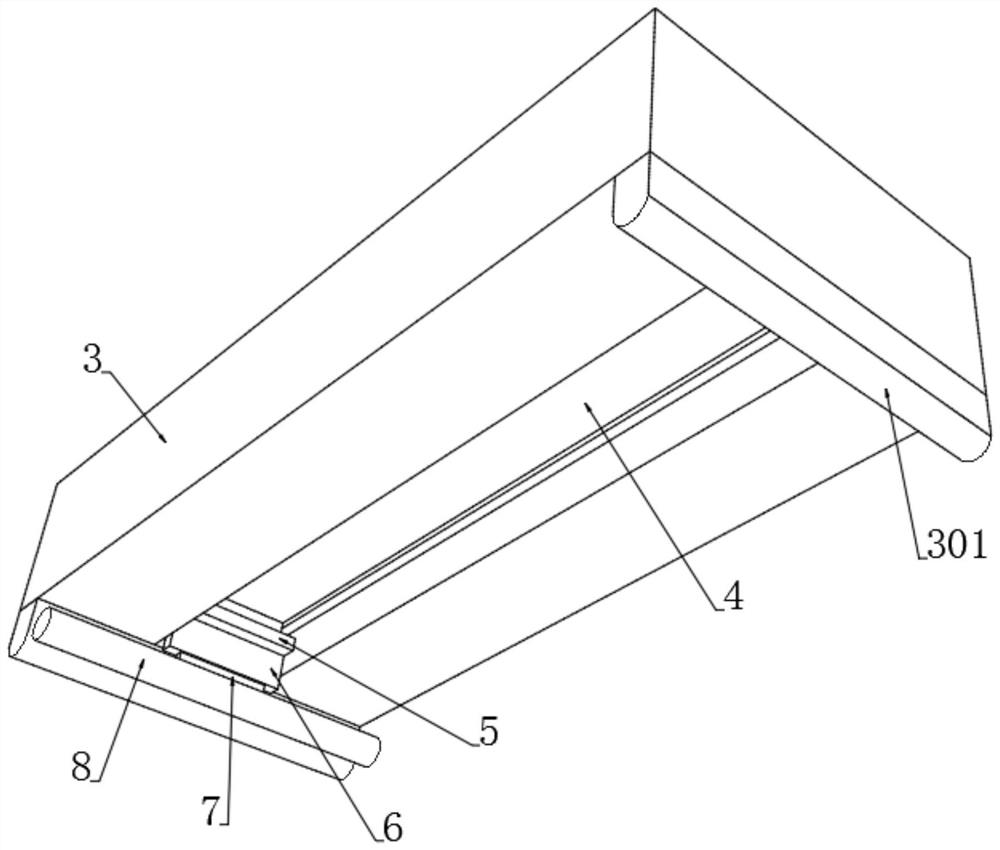

Embodiment 1

[0042] see Figure 1-4 , a defoaming type semiconductor chip packaging device, including a movable template 2 and a fixed template 1 arranged up and down, the fixed template 1 and the four corners of the movable template 2 are connected by hydraulic rods, and the upper end of the fixed template 1 is provided with a casting cavity , the bottom end of the movable template 2 is provided with an encapsulation seat 3 which is adapted to the pouring cavity, and both sides of the lower end of the encapsulation seat 3 are provided with elliptical guide seats 301. The electric sliding rail 4 is installed in the cavity, and the electric sliding rail 4 is connected with an intelligent lifting piece through the connecting plate 5. The bottom end of the intelligent lifting piece is connected with a magnetic bearing 8 that is flush with the bottom end surface of the oval guide seat 301. 3. The lower end is tightly covered with a flexible bag 11, and the bottom end wall of the flexible bag 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com