Novel fiber clothing material with anti-ultraviolet function

An anti-ultraviolet, new material technology, applied in the field of textile fabrics, can solve the problems of loss of efficacy, poor ultraviolet resistance, single anti-radiation or antibacterial function, etc., to reduce penetration and avoid impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

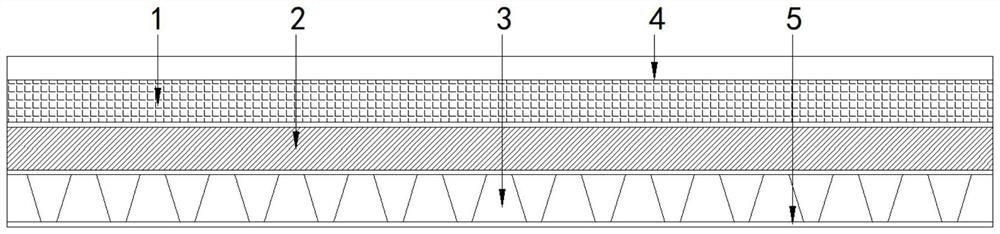

[0022] see figure 1 , The present invention provides a technical solution: a new fiber clothing material with anti-ultraviolet function, comprising: a fiber fabric layer, a heating fabric layer and a skin-friendly layer, the fiber fabric layer is attached to the surface of the heating fabric layer, and the heating fabric layer is attached On the surface of the skin-friendly layer, an adhesion layer is arranged between the fiber fabric layer, the heating fabric layer and the skin-friendly layer. The inner surface of the layer is provided with an antibacterial layer, and the fiber fabric layer is made by interweaving warp and weft vertically with each other, and the warp is anti-ultraviolet fiber;

[0023] The preparation method of anti-ultraviolet fiber comprises the following steps:

[0024] S1: Dissolve cellulose acetate in a solvent to prepare a solution with a weight percentage of 0.03 to 0.3 wt%, and then fully stir the solution to completely dissolve;

[0025] S2: addin...

Embodiment 2

[0034] see figure 1 , The present invention provides a technical solution: a new fiber clothing material with anti-ultraviolet function, comprising: a fiber fabric layer, a heating fabric layer and a skin-friendly layer, the fiber fabric layer is attached to the surface of the heating fabric layer, and the heating fabric layer is attached On the surface of the skin-friendly layer, an adhesion layer is arranged between the fiber fabric layer, the heating fabric layer and the skin-friendly layer. The inner surface of the layer is provided with an antibacterial layer, and the fiber fabric layer is made by interweaving warp and weft vertically with each other, and the warp is anti-ultraviolet fiber;

[0035] The preparation method of anti-ultraviolet fiber comprises the following steps:

[0036] S1: Dissolve cellulose acetate in a solvent to prepare a solution with a weight percentage of 0.03 to 0.3 wt%, and then fully stir the solution to completely dissolve;

[0037] S2: addin...

Embodiment 3

[0046] see figure 1 , The present invention provides a technical solution: a new fiber clothing material with anti-ultraviolet function, comprising: a fiber fabric layer, a heating fabric layer and a skin-friendly layer, the fiber fabric layer is attached to the surface of the heating fabric layer, and the heating fabric layer is attached On the surface of the skin-friendly layer, an adhesion layer is arranged between the fiber fabric layer, the heating fabric layer and the skin-friendly layer. The inner surface of the layer is provided with an antibacterial layer, and the fiber fabric layer is made by interweaving warp and weft vertically with each other, and the warp is anti-ultraviolet fiber;

[0047] The preparation method of anti-ultraviolet fiber comprises the following steps:

[0048] S1: Dissolve cellulose acetate in a solvent to prepare a solution with a weight percentage of 0.03%, and then fully stir the solution to completely dissolve;

[0049] S2: add 0.01 of ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com