Control device and method for assembling sectors of turbine stator of turbine

A technology of a control device and a control method, applied in the fields of aero-engines and turbines, can solve problems such as quality loss and error sources, and achieve the effects of improving efficiency and profitability, being easy to reproduce, and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

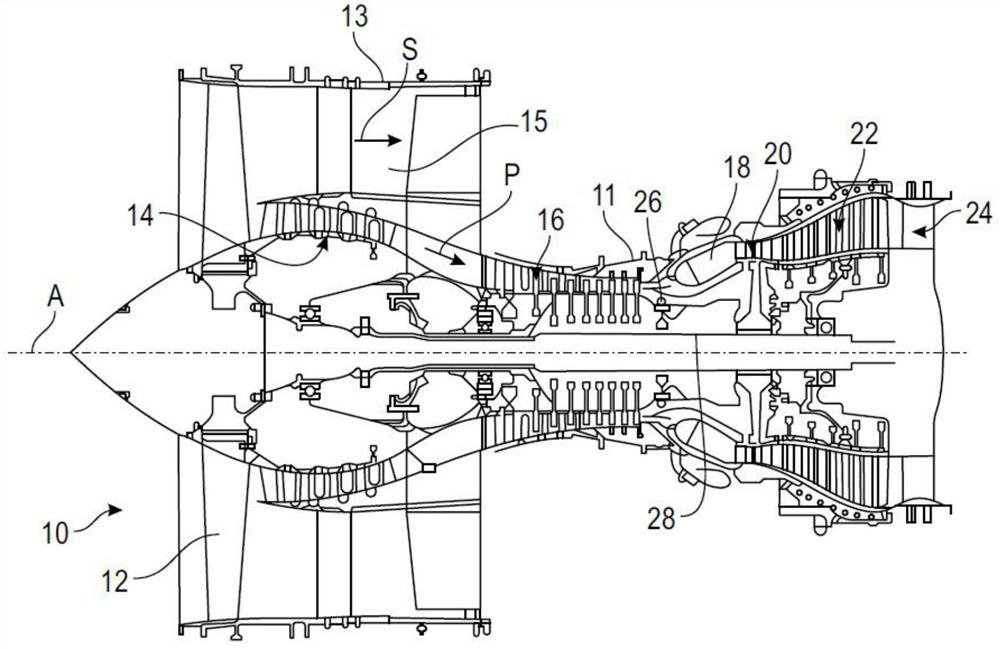

[0068] figure 1 A turbomachine 10 of the twin-flow type with a longitudinal axis A is shown. Such a turbine 10 (here a turbojet 10 ) includes a fan 12 , a low pressure (LP) compressor 14 , a high pressure (HP) compressor 16 , a combustor 18 , a high pressure (HP) turbine 20 , a low pressure (LP) compressor 16 in a known manner LP) turbine 22 and exhaust nozzle 24 . The rotor of the HP compressor 16 and the rotor of the HP turbine 20 are connected by the high pressure HP shaft 26 and form a high pressure body with the high pressure HP shaft 26 . The rotor of the LP compressor 14 and the rotor of the low pressure LP turbine 22 are connected by the LP shaft 28 and form a low pressure body with the LP shaft 28 .

[0069] The primary air flow "P" passes through the high and low pressure bodies, and the fan 12 produces a secondary air flow "S" in the cold flow passage 15, which is The casing 11 and the outer casing 13 communicate with each other. At the outlet of the nozzle 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com