Automobile body welding process quality score prediction method and device based on LSTM (Long Short Term Memory) model

A scoring prediction and welding process technology, applied in the field of auto body welding process quality scoring prediction, can solve the problems of lack of intelligent application, high labor cost, poor timeliness, etc., and achieve the effect of improving maintenance accuracy and reducing maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

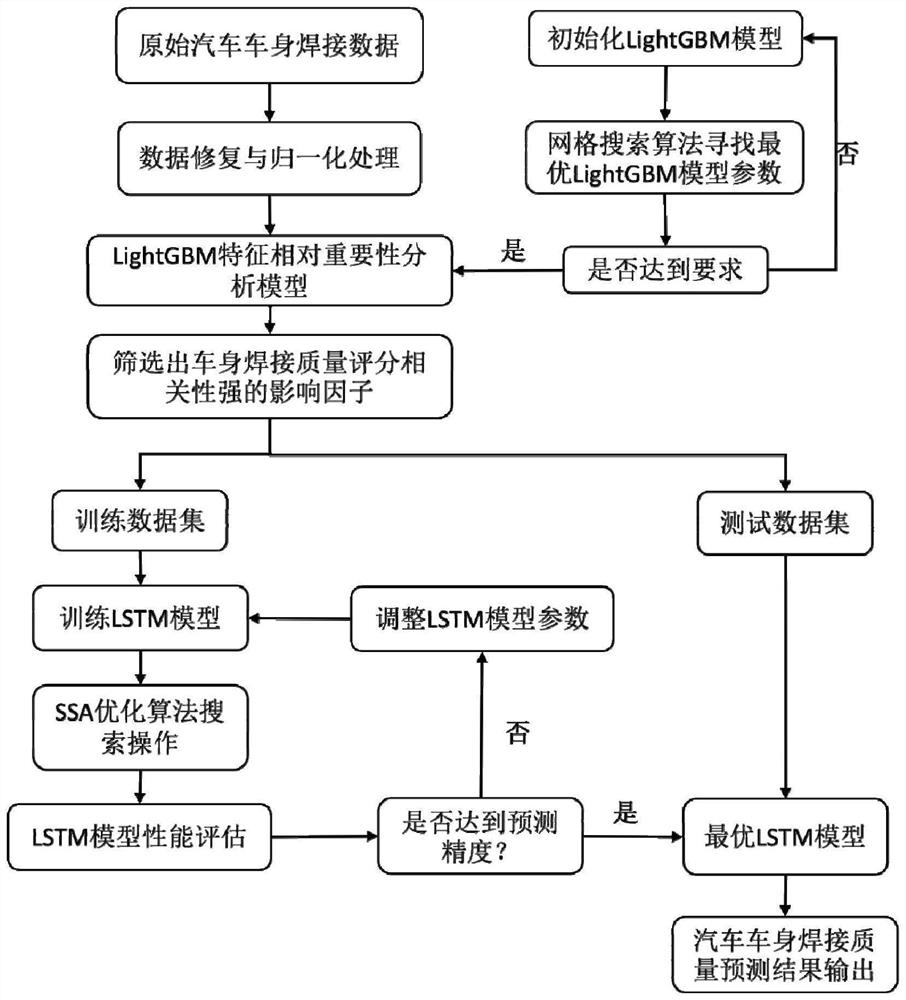

[0051] Example 1: Take the LightGBM model as an example

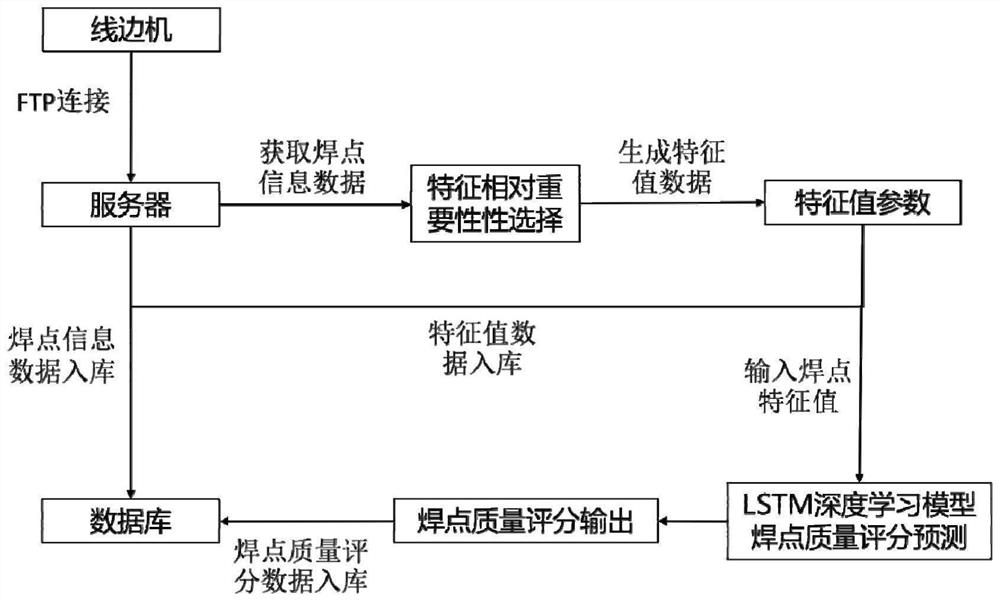

[0052] Such as figure 2 As shown, the LightGBM model is deployed on the online server. This model can identify the path of the data feature value transmitted to the server, and judge whether there is new data and what new data is generated by reading the feature value data on the fixed path in real time. ; If new data is found, follow up the identification scheme of the corresponding solder joint type in real time, extract the feature data set, and generate a data screening file to save to a fixed path; if not found, the online system will not be triggered to perform feature comparison Importance selection model.

[0053] After the collected solder joint information data passes through the LightGBM model, the characteristic value parameters will be generated. While saving the characteristic value parameters to the solder joint information database, the system will detect that new characteristic data is generated in th...

Embodiment 2

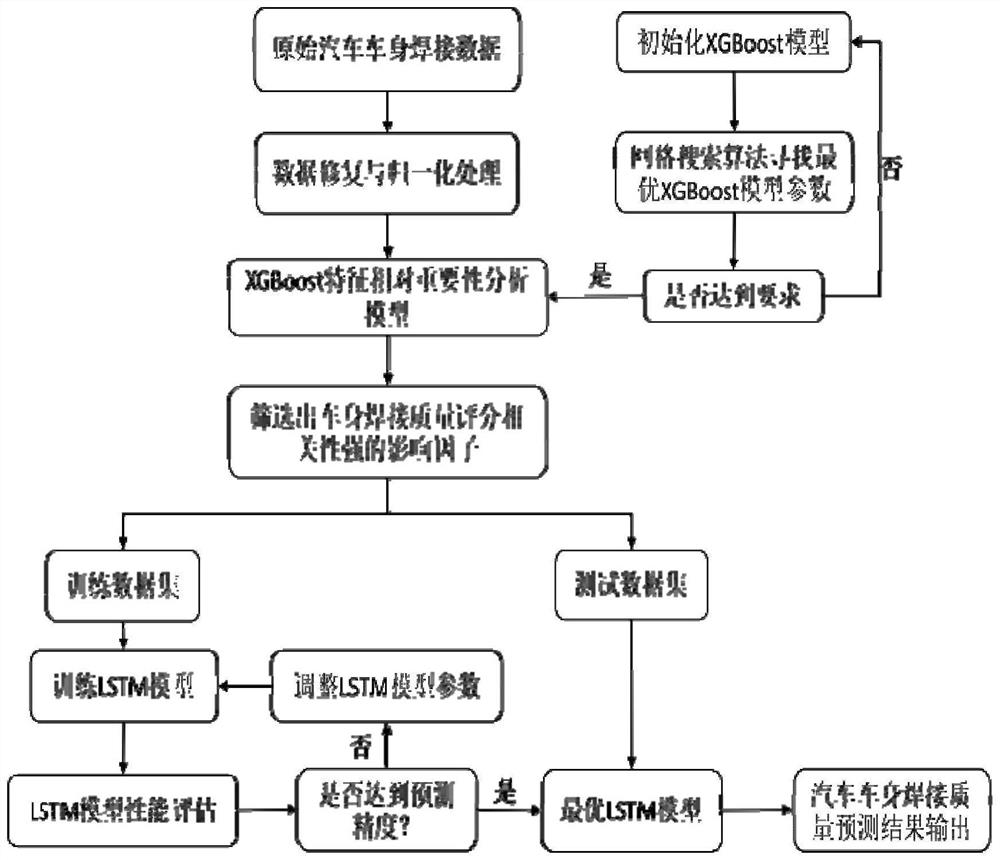

[0080] Example 2: Taking the XGBoost model as an example

[0081] Such as image 3 As shown, the XGBoost model is deployed on the online server. This model can identify the path of the data feature value transmitted to the server, and judge whether there is new data and what new data is generated by reading the feature value data on the fixed path in real time. ; If new data is found, follow up the identification scheme of the corresponding solder joint type in real time, extract the feature data set, and generate a data screening file to save to a fixed path; if not found, the online system will not be triggered to perform feature comparison Importance selection model.

[0082] After the collected solder joint information data passes through the XGBoost model, eigenvalue parameters will be generated. While saving the eigenvalue parameters to the solder joint information database, the system will detect that new feature data is generated in the fixed path, and then trigger LS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com