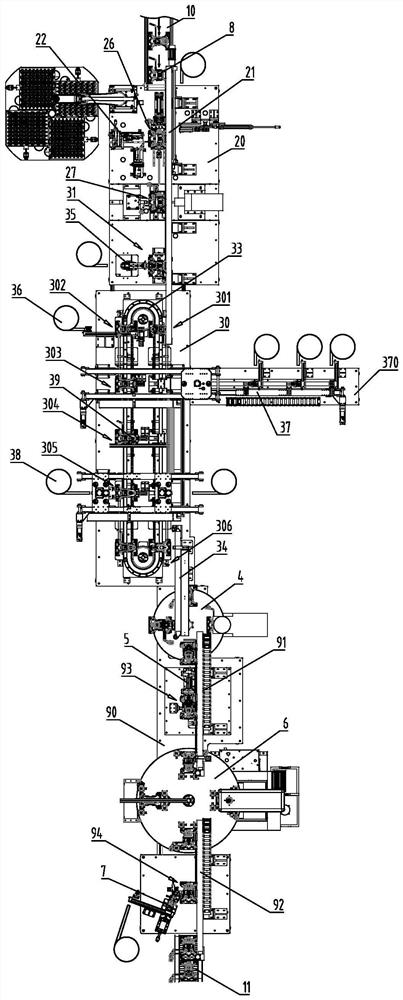

Automatic assembling equipment for seat tray adjusting mechanism

An adjustment mechanism and automatic assembly technology, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of low efficiency, increased seat tray assembly cost, time-consuming and labor-intensive problems, and achieve reasonable position distribution and automatic assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

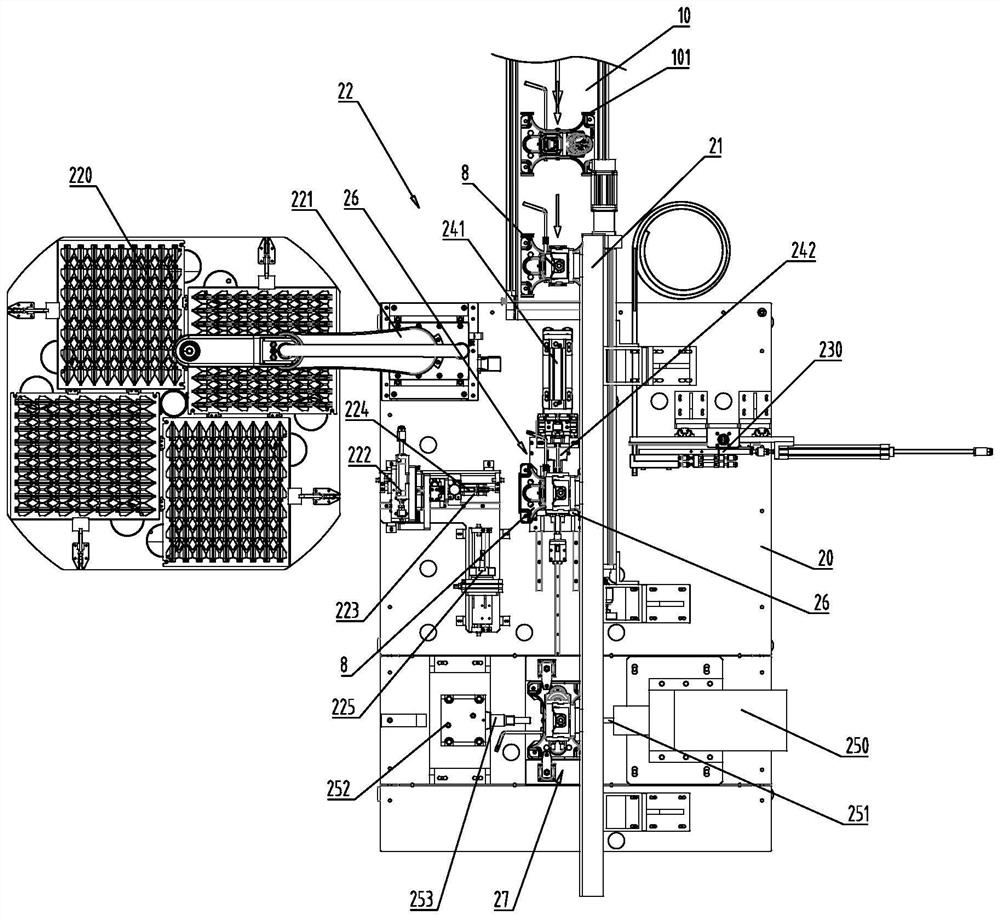

Method used

Image

Examples

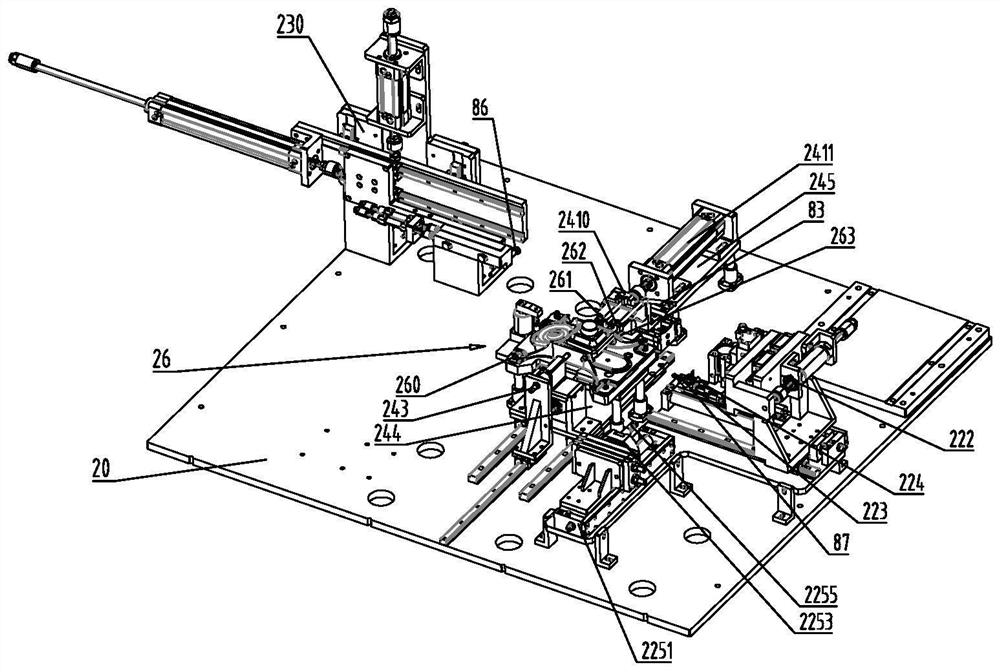

Embodiment 1

[0093] like Figure 26 The shown seat tray 8 includes a chassis 80, a movable seat 81, a conical tube 82, an adjusting rod 83, a handle member 84, a paddle 85, a locking mechanism for controlling the lifting of the seat, and a locking mechanism for adjusting the seat. Tilt tension adjustment mechanism 88, the locking mechanism includes a torsion spring assembly 87 and a connecting rod 86, the torsion spring assembly 87 includes a fixedly connected connecting block and a first torsion spring, the movable seat 81 is connected to the movable seat 81 through the connecting rod 86. The chassis 80 is hinged, the connecting block is hollowly sleeved on the connecting rod 86, the torsion spring is fixedly connected with the connecting block and can generate a force on the conical tube 82, and the adjusting mechanism 88 includes a threaded rod 880 and a sleeve Compression spring 881, plastic sleeve 882, plastic cover 883, adjusting nut 8831, forming washer 885 and flat washer 886 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com