Omnibearing detection mechanical arm of mining robot

A technology of manipulators and robots, which is applied in the field of all-round detection manipulators for mining robots, can solve problems such as narrow corners and inaccessibility of mining robots, and achieve the effect of improving work efficiency and ensuring mine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

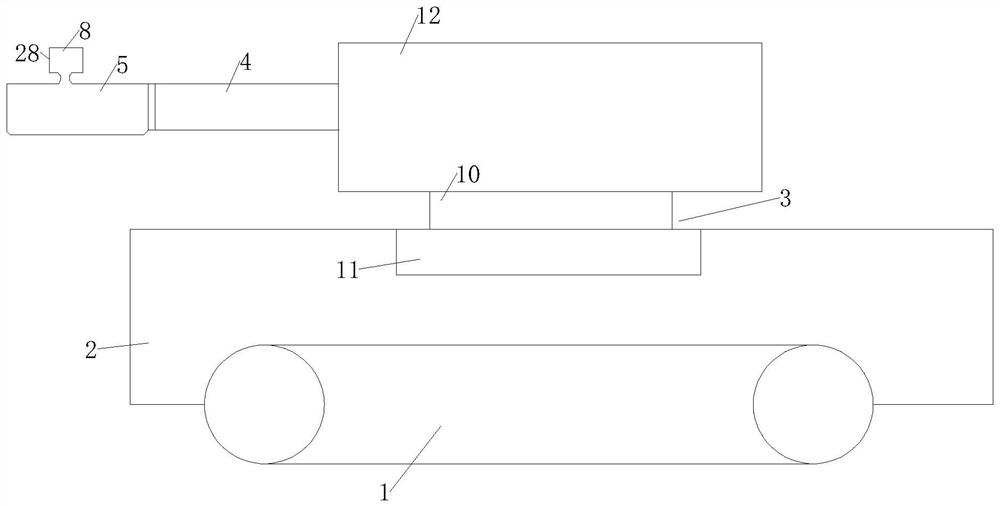

[0066] As a specific embodiment of the present invention, the rotating assembly 3 further includes:

[0067] a rotating shaft 10, the rotating shaft 10 is located above the vehicle frame 2 and is rotatably connected with the vehicle frame 2;

[0068] No. 1 motor 11, the output shaft of the No. 1 motor 11 is fixedly connected to the rotating shaft 10;

[0069] a base 12, the base 12 is located above the rotating shaft 10 and is fixedly connected with the rotating shaft 10;

[0070] When the No. 1 motor 11 is started, it drives the rotating shaft 10 fixedly connected to the output shaft of the No. 1 motor 11 to also rotate, thereby driving the base 12 fixedly connected to the other end of the rotating shaft 10 to also rotate, so that the base 12 fixedly connected to the base 12 also rotates. The manipulator support 4 also rotates following the base 12, so that the detection manipulator 5 connected to the manipulator support 4 can detect the surrounding environment.

[0071] As...

Embodiment approach

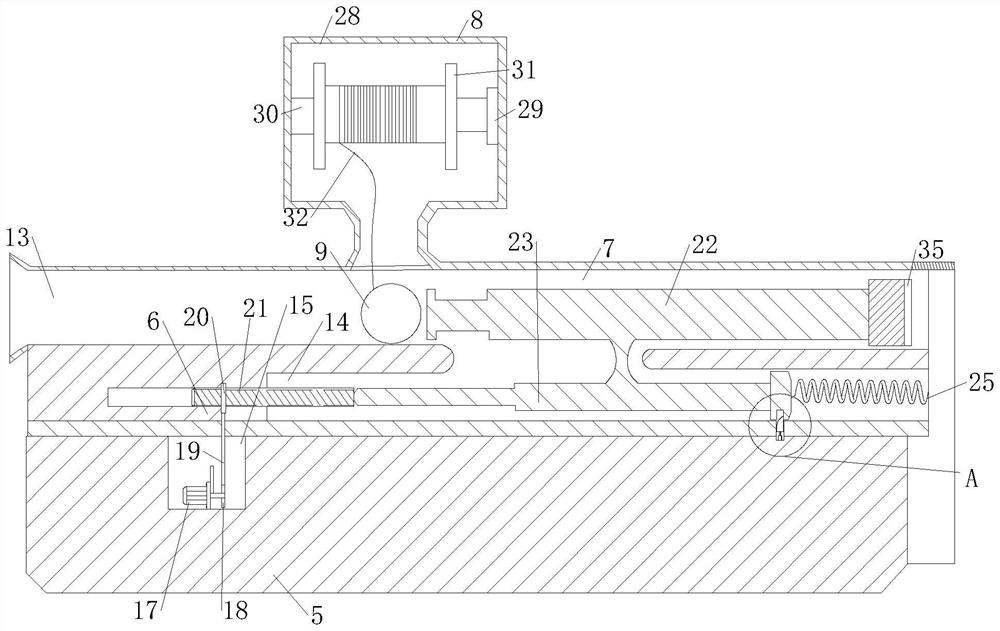

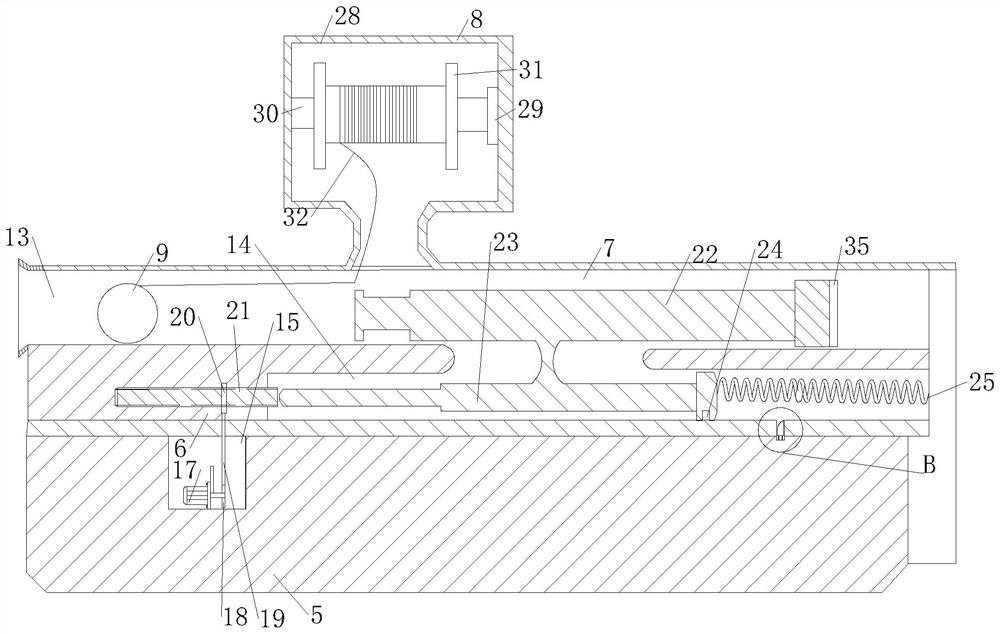

[0096] As a specific embodiment of the present invention, an annular flexible rubber 34 is fixedly connected to the outer surface of the detection ball 9 .

[0097] In order to prevent the detection ball 9 from being broken when it is launched and landed, a ring-shaped flexible rubber 34 is provided on the surface of the detection ball 9. The flexible rubber 34 surrounds the detection ball 9 and has holes at the position of the detection element 33 to prevent the detection element from being blocked. 33 line of sight, while protecting the detection ball 9.

[0098] As a specific embodiment of the present invention, the flexible wire 32 is made of ultra-high molecular weight polyethylene fiber material.

[0099] The ultra-high molecular weight polyethylene fiber material has good wear resistance, weather resistance and corrosion resistance and flexibility.

[0100] As a specific embodiment of the present invention, a flexible rubber 35 is provided at one end of the No. 2 rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com