Cooling forming device for cable core wire sheath processing

A molding device and core wire technology, which is applied in the field of cable core wire sheath, can solve the problems of poor cooling effect, slow water temperature rise, unfavorable core wire sheath forming, etc., to increase fit, reduce friction, The effect of smooth card connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

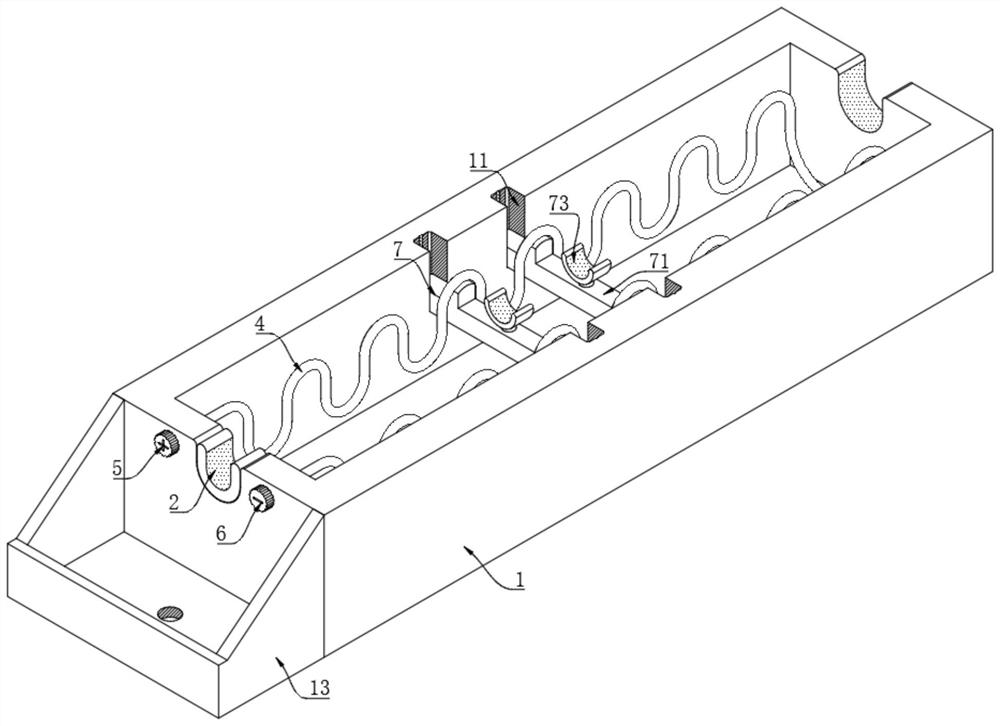

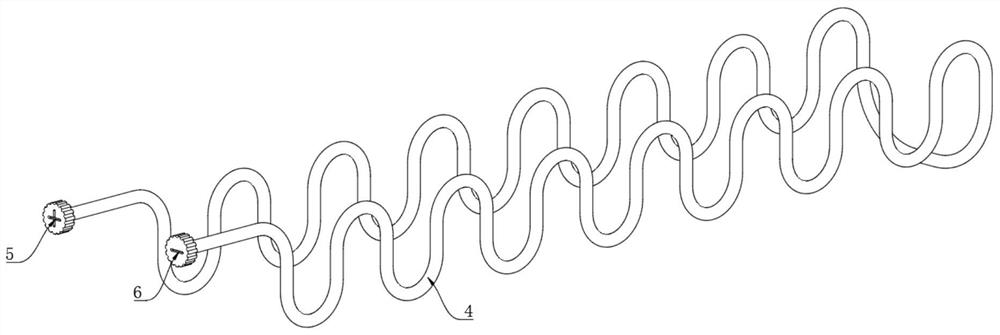

[0027] see Figure 1 to Figure 6 , The embodiment of the present invention provides a cooling and forming device for processing a cable core wire sheath. The cooling and forming device for processing a cable core wire sheath includes: a water tank 1, and also includes: a placing plate 2, the water tank 1 There is a placing plate 2 for accommodating the core wire sheath; a return pipe 4, the return pipe 4 is located in the water tank 1, and the return pipe 4 circulates cooling liquid, and the water in the water tank 1 Cool down; support assembly 7, the water tank 1 is fitted with a support assembly 7, and the support assembly 7 is used to support the return pipe 4 and the core wire sheath.

[0028] It should be noted that a return pipe 4 that can be injected with cooling liquid is provided in the water tank 1, so that when the core wire sheath is cooled and formed, the water in the water tank 1 will not change with the temperature of the core wire sheath itself. There is a phe...

Embodiment 2

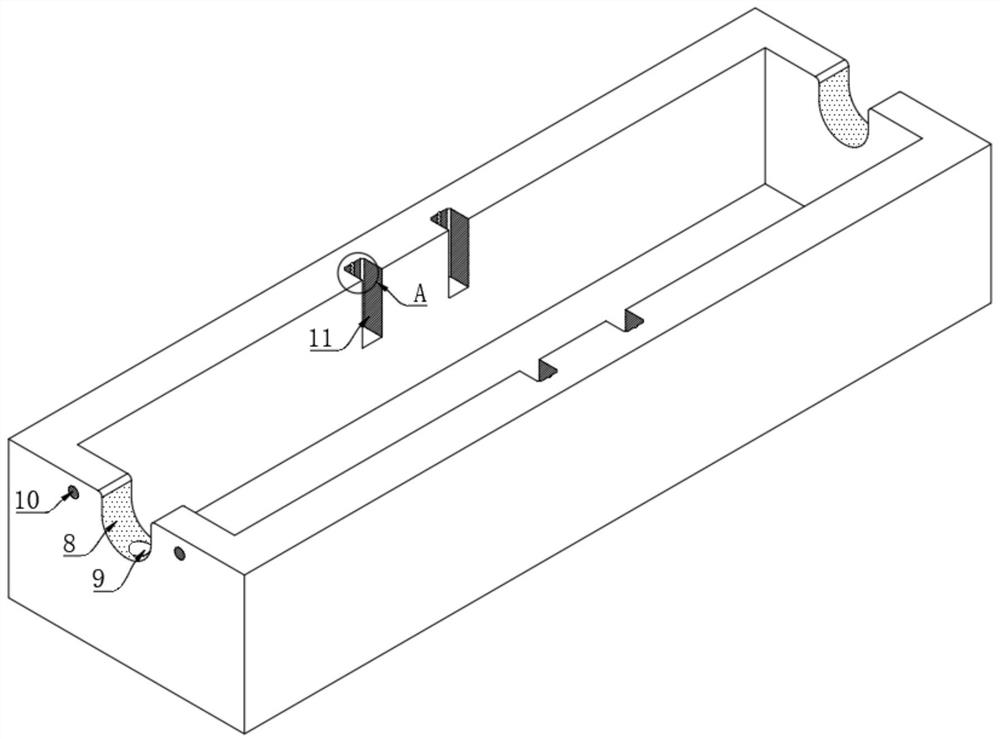

[0034] In an embodiment of the present invention, see figure 1 , figure 2 , Figure 4 and Image 6 , the upper surface of the water tank 1 and the positions close to both sides are provided with limit card slots 11, the support assembly 7 is embedded in the limit card slot 11, and the support assembly 7 includes a fixed card board 71, The fixed card board 71 is correspondingly clamped with the limit card slot 11 , the upper surface of the fixed card board 71 and the positions close to the edges on both sides are fixedly connected with the support bases 72 , and the upper surface of the fixed card board 71 is fixedly connected with the support seat 72 . And the central position is fixedly connected with a support bracket 73 through a connecting column, and the structure of the support bracket 73 is consistent with the structure of the placing plate 2 .

[0035] It should be noted that: when the core wire sheath is cooled and formed, the staff needs to install the supporting...

Embodiment 3

[0041] In an embodiment of the present invention, see figure 1 , figure 2 , image 3 and Figure 4 One side of the water tank 1 is provided with two circular holes 10 arranged in mirror images. The water outlet hole passes through the other circular hole 10 and is connected with the water outlet valve port 6 . The upper surface of the support seat 72 is of an arc structure and is in conflict with the arc surface of the return pipe 4 .

[0042] It should be noted that: after the support assembly 7 is fixed, and then the return pipe 4 is installed, the staff will make the water outlet hole and the water inlet hole on the return pipe 4 correspond to the positions of the two round holes 10 on the water tank 1 , so that the water outlet hole runs through one of the circular holes 10 , and the water inlet hole runs through the other circular hole 10 . The surfaces are in contact with each other, so that the support seat 72 supports the return pipe 4. After that, the staff insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com