Preparation method of bi-component elastic composite fiber

An elastic composite fiber, two-component technology, applied in fiber processing, melt spinning, yarn, etc., can solve problems such as floating yarn, short cleaning cycle, spinning end breakage, etc., achieve small orifice circumference, improve cleaning The effect of plate cycle and difficulty in agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a bicomponent elastic composite fiber, the specific process is as follows:

[0030] Two-component elastic composite fibers are prepared by composite spinning of two different polymer melts;

[0031] The overall process flow is: melt extrusion→cooling and solidification→cluster oiling→winding forming;

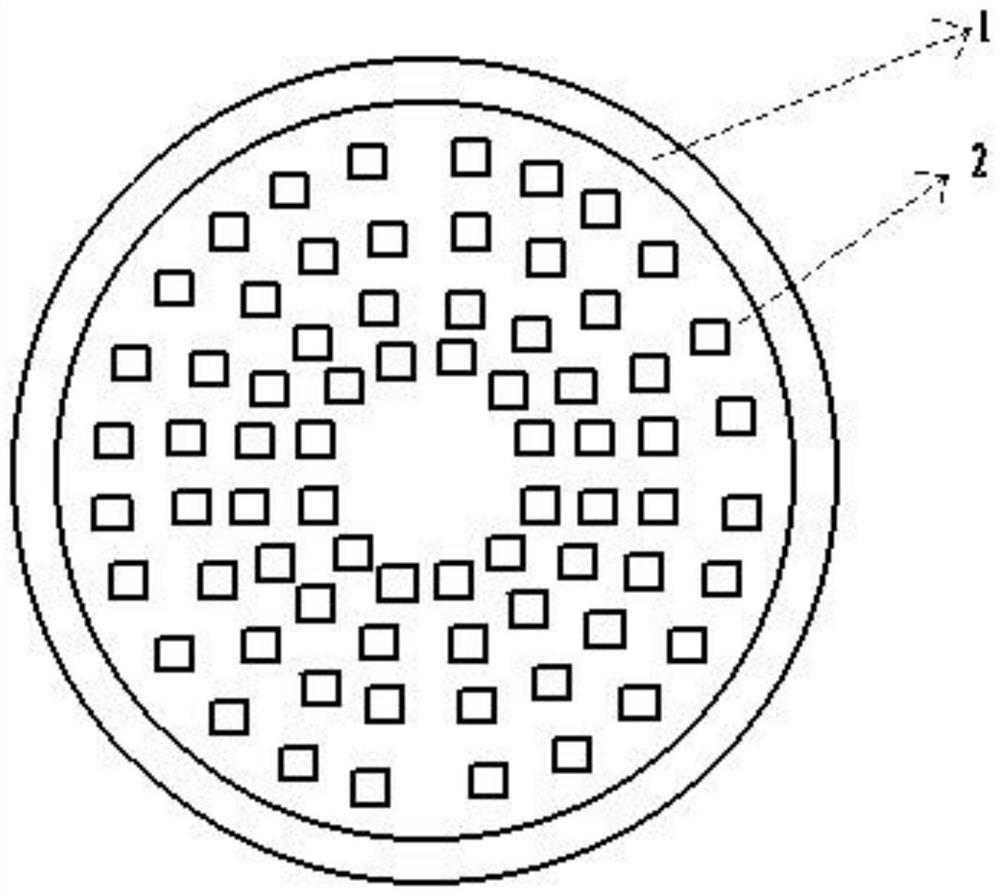

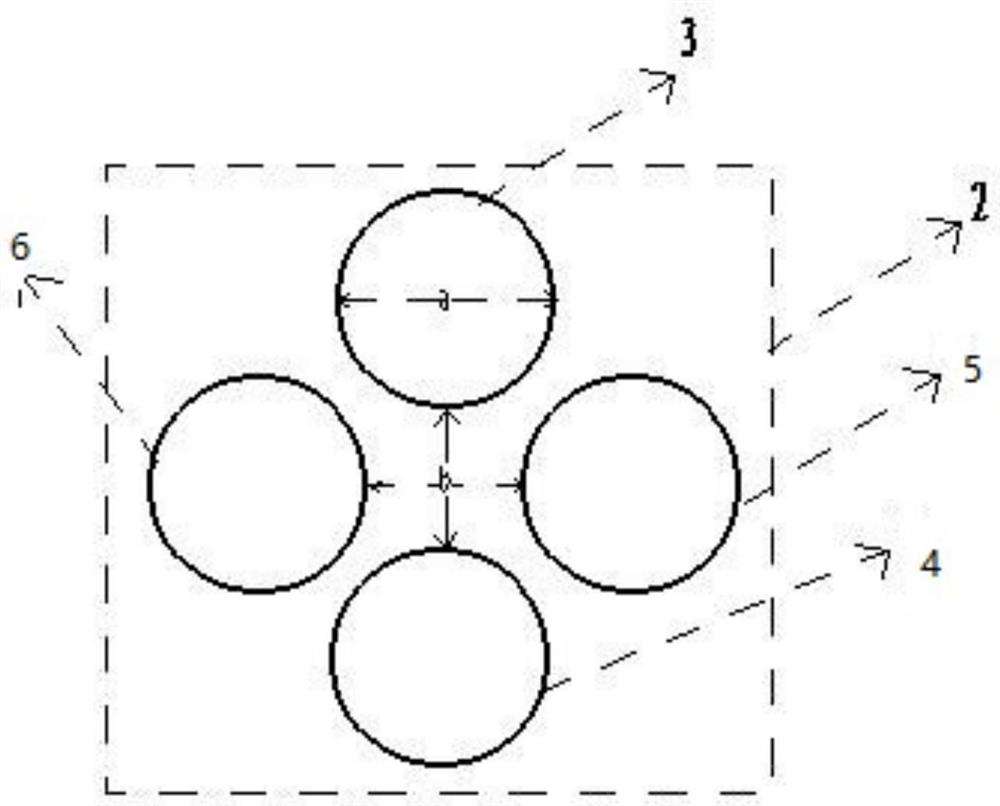

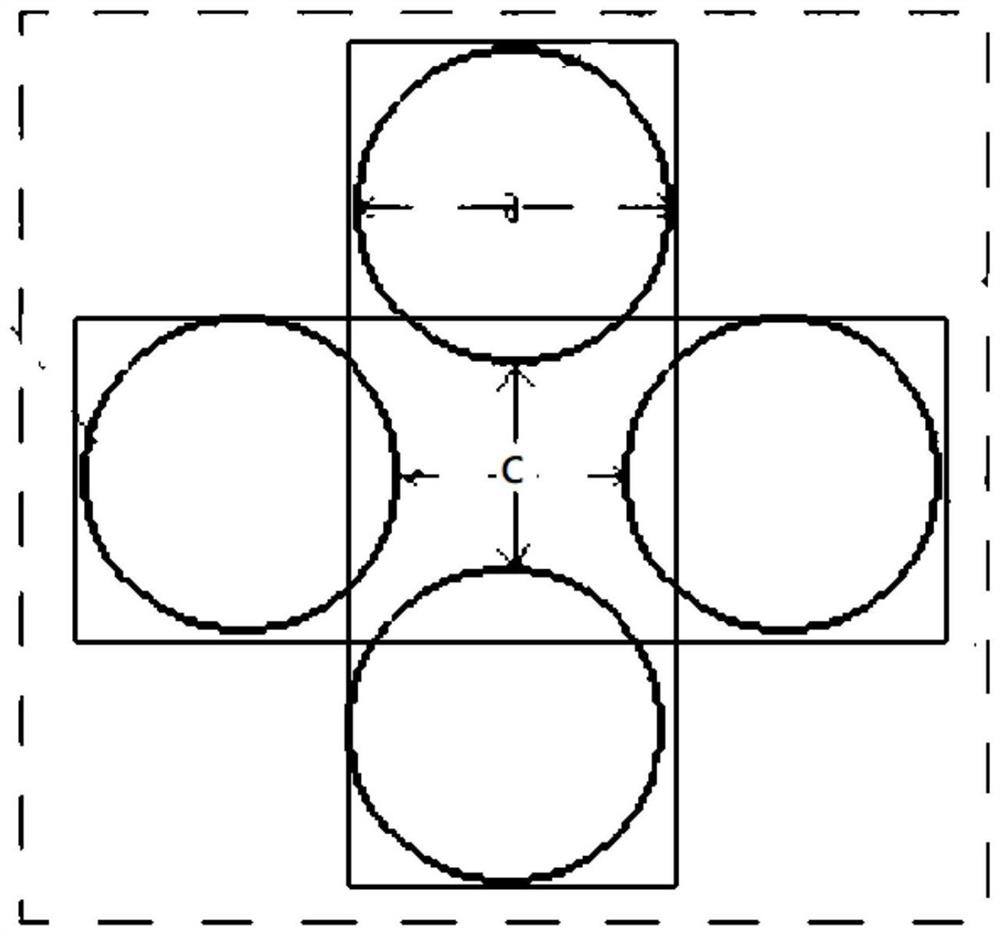

[0032] Among them, such as Figures 1 to 2 As shown, the spinneret 1 used for composite spinning is provided with 72 unit spinneret combination holes 2; each unit spinneret combination hole 2 consists of a group of opposite circular spinneret holes I and circular spinneret holes II 4 and another group of opposite circular orifices III 5 and circular orifices IV 6 are formed, circular orifices I 3, circular orifices II 4, circular orifices III 5 and circular The center of the spinneret IV 6 is located at the midpoint of the four sides of the square, respectively, the circular spinneret I3, the circular spinneret II 4, the circular spinneret III 5 ...

Embodiment 2

[0045] A preparation method of a bicomponent elastic composite fiber, the specific process is as follows:

[0046] Two-component elastic composite fibers are prepared by composite spinning of two different polymer melts;

[0047] The overall process flow is: melt extrusion→cooling and solidification→cluster oiling→winding forming;

[0048] Among them, the spinneret used for composite spinning is provided with 72 unit spinneret combination holes; each unit spinneret combination hole consists of a group of opposite circular spinneret holes I and II and another group of opposite circular spinneret holes Holes III and IV are formed, the centers of the circular spinneret holes I to IV are respectively located at the midpoints of the four sides of the square, and the diameters of the circular spinneret holes I to IV are the same as 0.14mm. The spacing of II is 0.1mm; the length-diameter ratio of the circular spinneret holes I to IV is the same as 4; the spacing between two adjacent...

Embodiment 3

[0054] A preparation method of a bicomponent elastic composite fiber, the specific process is as follows:

[0055] Two-component elastic composite fibers are prepared by composite spinning of two different polymer melts;

[0056] The overall process flow is: melt extrusion→cooling and solidification→cluster oiling→winding forming;

[0057] Among them, the spinneret used for composite spinning is provided with 144 unit spinneret combination holes; each unit spinneret combination hole consists of a group of opposite circular spinneret holes I and II and another group of opposite circular spinneret holes Holes III and IV are formed, the centers of the circular spinneret holes I to IV are respectively located at the midpoints of the four sides of the square, and the diameter a of the circular spinneret holes I to IV is the same as 0.13mm, and the circular spinneret holes I The distance c between and II is 0.1mm; the length-diameter ratio of the circular spinneret holes I to IV is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com