Method for judging sensitivity of reheat cracks in coarse grain area

A technology for reheating cracks and coarse-grained areas, which is applied in the direction of strength characteristics, preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc. Inaccurate evaluation of crack sensitivity, inaccurate measurement of sample cross-sectional area, etc., to achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are to explain rather than limit the present invention.

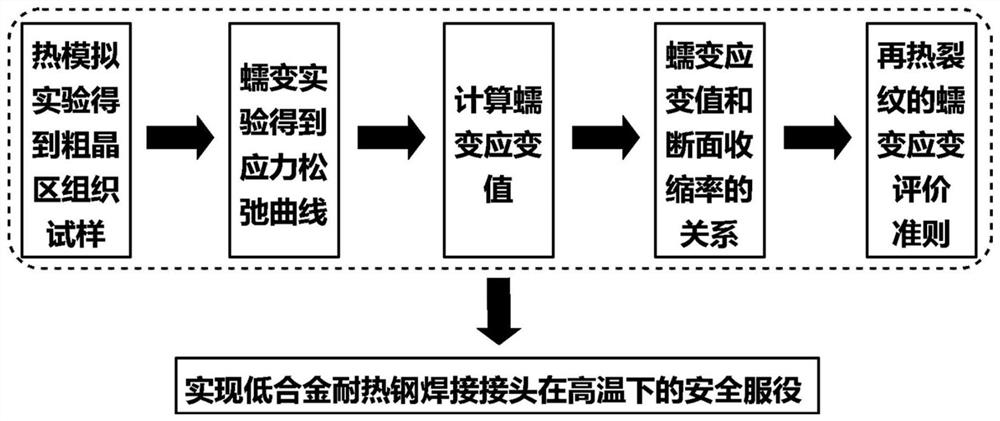

[0028] like figure 1 , the method for evaluating the reheat crack susceptibility of the coarse-grained region of the present invention includes:

[0029] In the first step, technicians take samples longitudinally along the steel pipe or steel rod by machining. The total length of the processed rod-shaped sample is 150mm, the length of the test section is 10mm, the diameter of the test section is φ6mm, the clamping section is M10mm, and the transition angle is 45°, the surface temperature of the sample during processing does not exceed 100°C, and the surface of the sample after processing is smooth and free of burrs;

[0030] In the second step, according to the actual welding parameters of the low-alloy heat-resistant steel, calculate the welding heat input Q=ηUI / v and measure or simulate the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com