Low-loss heat dissipation module

A heat dissipation module and low-loss technology, which is applied in substation/switch layout details, reactive power adjustment/elimination/compensation, electrical components, etc., can solve problems such as poor heat dissipation effect, large volume, and complicated internal structure layout, and achieve high performance Stability, volume minimization, and convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

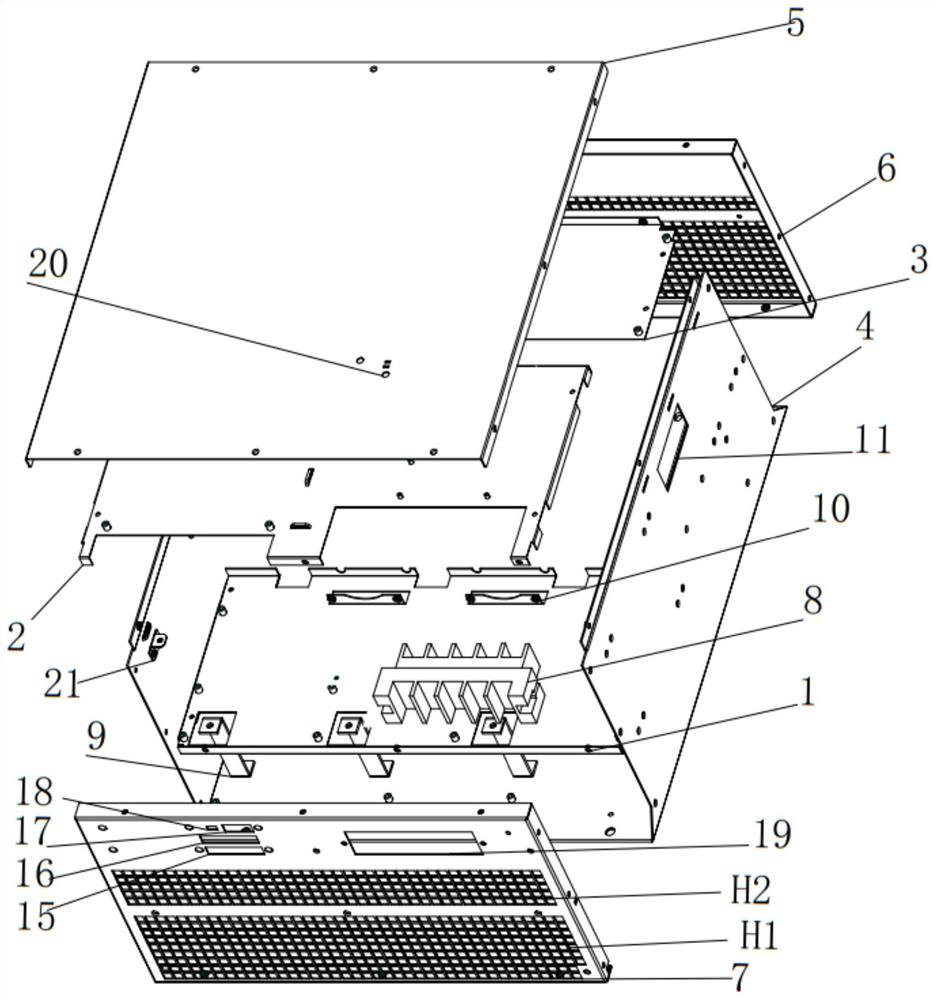

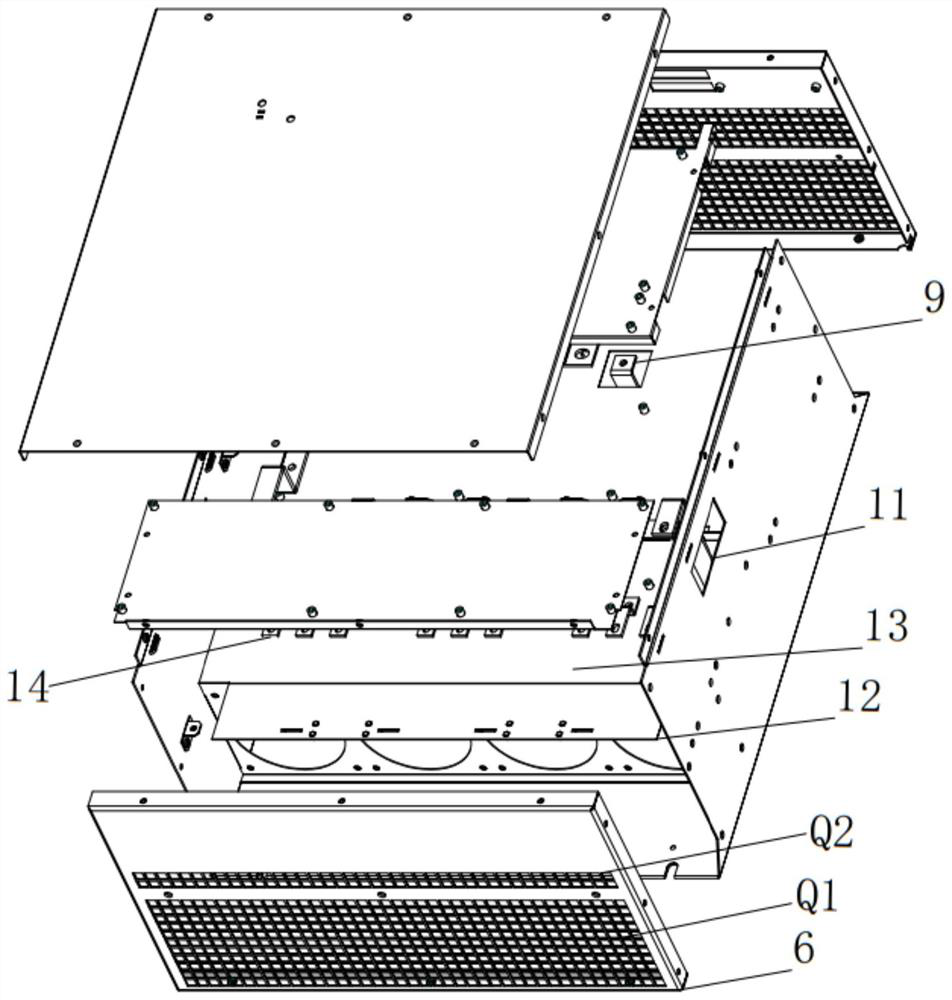

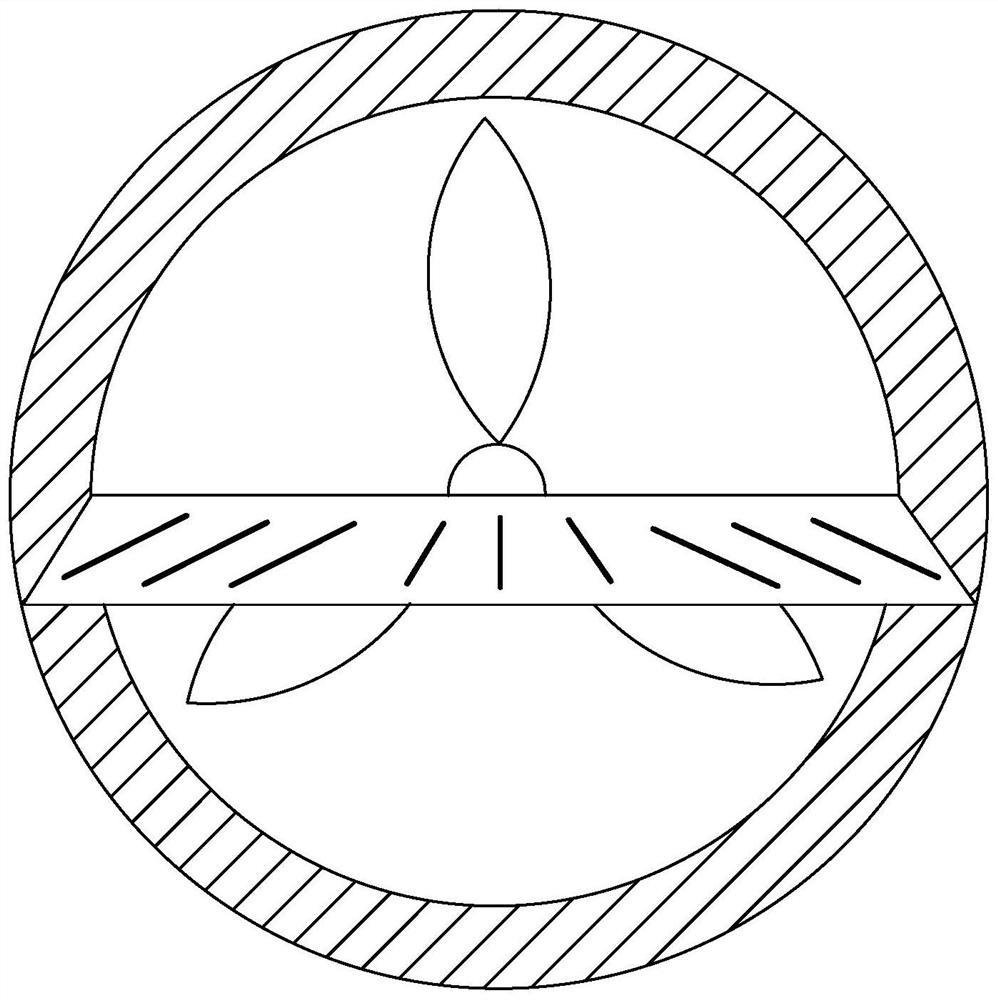

A low-loss heat dissipation module of this embodiment, such as figure 1As shown, it includes No. 1 supporting plate 1, No. 2 supporting plate 2, No. 3 supporting plate 3, box body 4, cover plate 5, front panel 6, rear panel 7, through-terminal 8, copper bar 9, fan fixing piece 10 , handle 11, fan mounting bracket 12, radiator 13, IGBT module 14, CT sampling interface 15, external communication interface 16, external control interface 17, DIP switch control port 18, through terminal interface 19, fan, indicator light 20 and The support plate fixing member 21, the cover plate 5, the front panel 6, the rear panel 7 and the box body 4 together form a closed container space. There are two heat dissipation hole areas on the front panel 6, the heat dissipation hole area at the bottom is the Q1 heat dissipation hole area, the heat dissipation hole area in the middle of the front panel 6 is the Q2 heat dissipation hole area; the rear panel 7 is provided with two heat dissipation hole ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com