Food waste treatment device

A technology for food waste treatment and food waste, which is applied in water supply installations, indoor sanitary plumbing installations, transportation and packaging, etc. It can solve the problems of solid content dregs accumulation, blockage of water discharge outlets, and stagnation, etc., to prevent foul odors , prevent clogging and stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

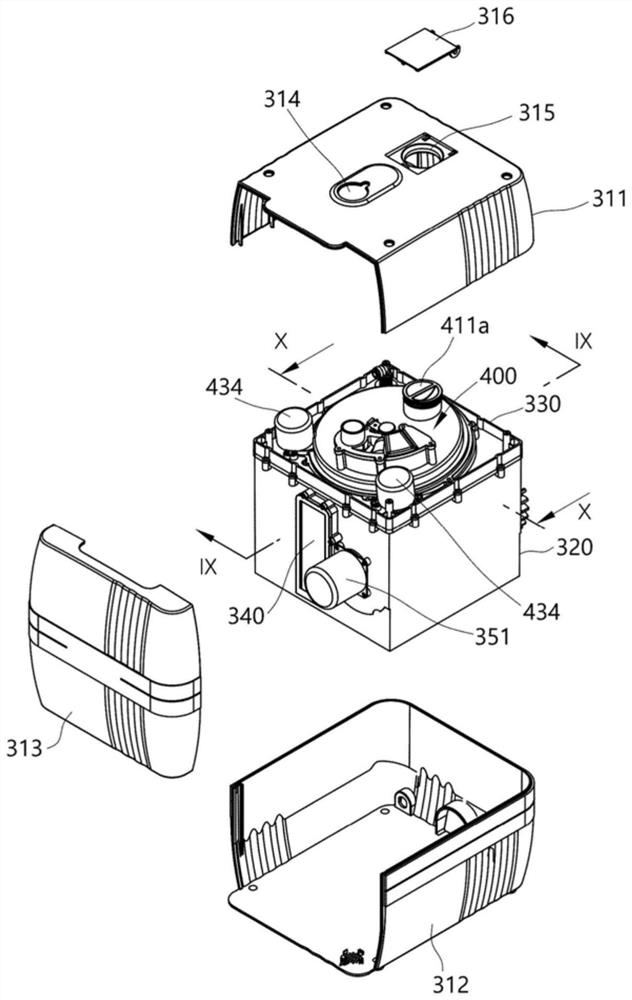

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0046] The food waste treatment apparatus according to the present invention is provided inside the washing tub to pulverize the mixture of food waste and wastewater containing moisture such as water (hereinafter referred to as "food waste") discharged through the drain port of the washing tub, using microorganisms to pulverize the pulverized food waste. Decomposition of food waste in order to fully decompose it or treat it to minimize food waste. In the description of the food waste processing apparatus according to the present invention, "pulverized product" is a concept of a product that is pulverized by a food waste pulverizer (100), a solid component including solids, and moisture such as water or waste water contained in it. use.

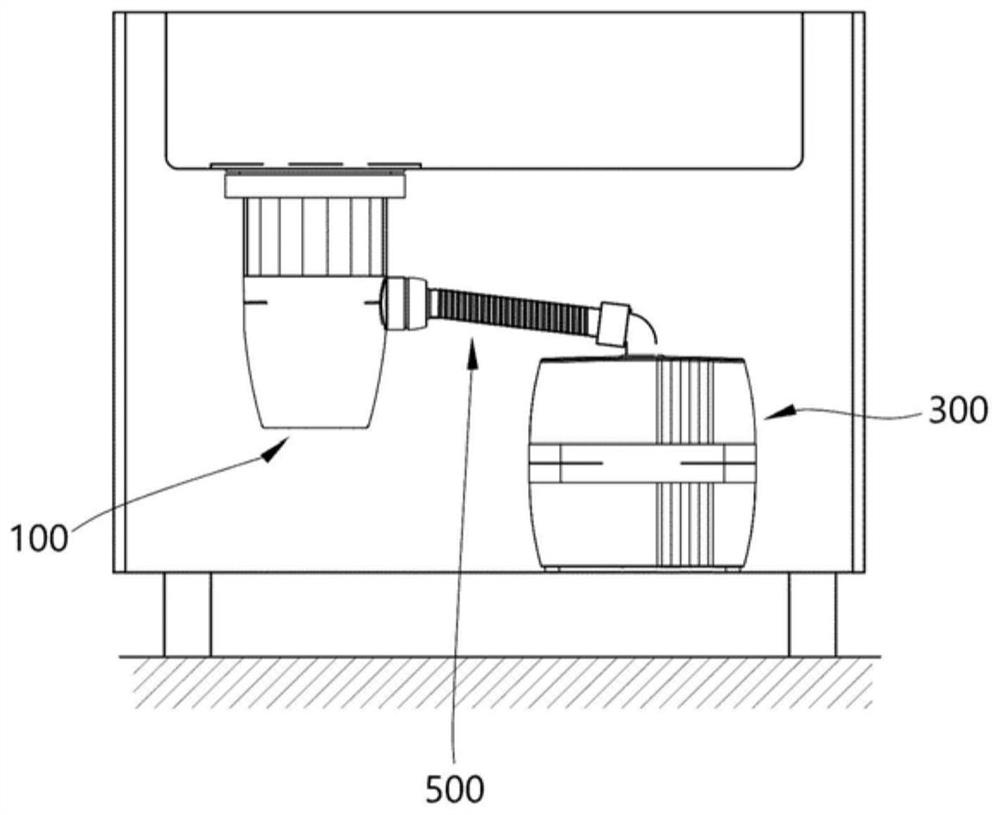

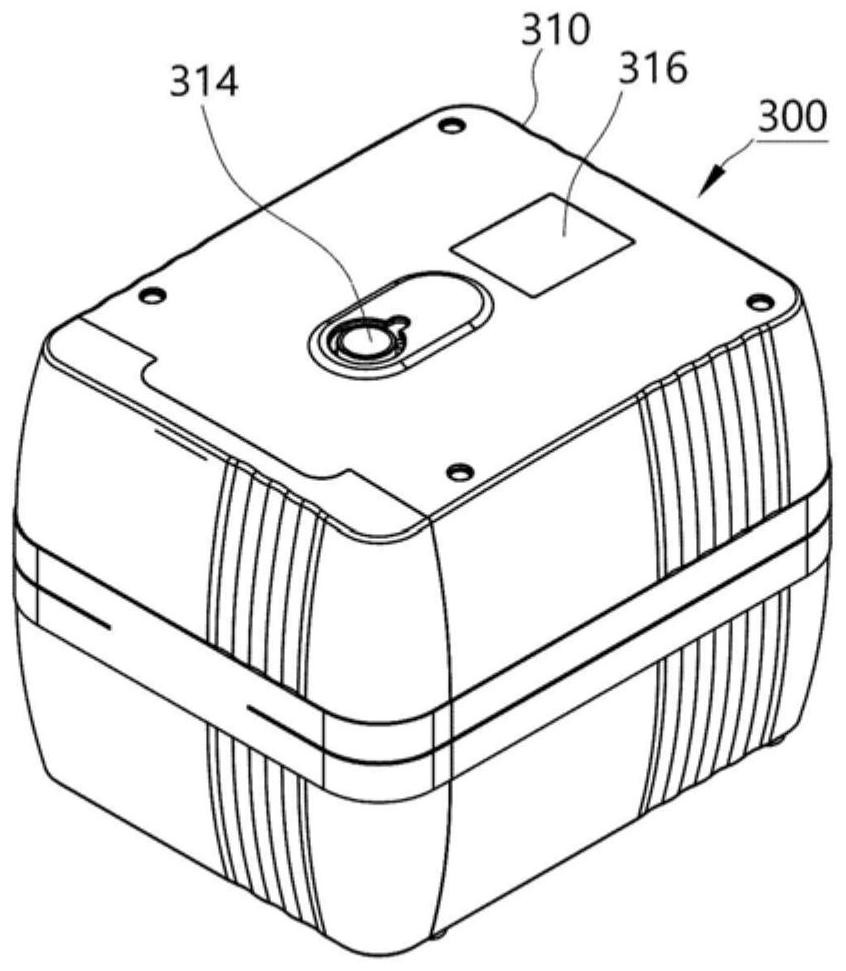

[0047] figure 1 is a diagram showing the structure of the food waste disposal apparatus according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com