Efficient and environment-friendly sedimentation tank for sewage treatment

An environmentally friendly sewage and sedimentation tank technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc. Improve flocculation effect and reduce waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

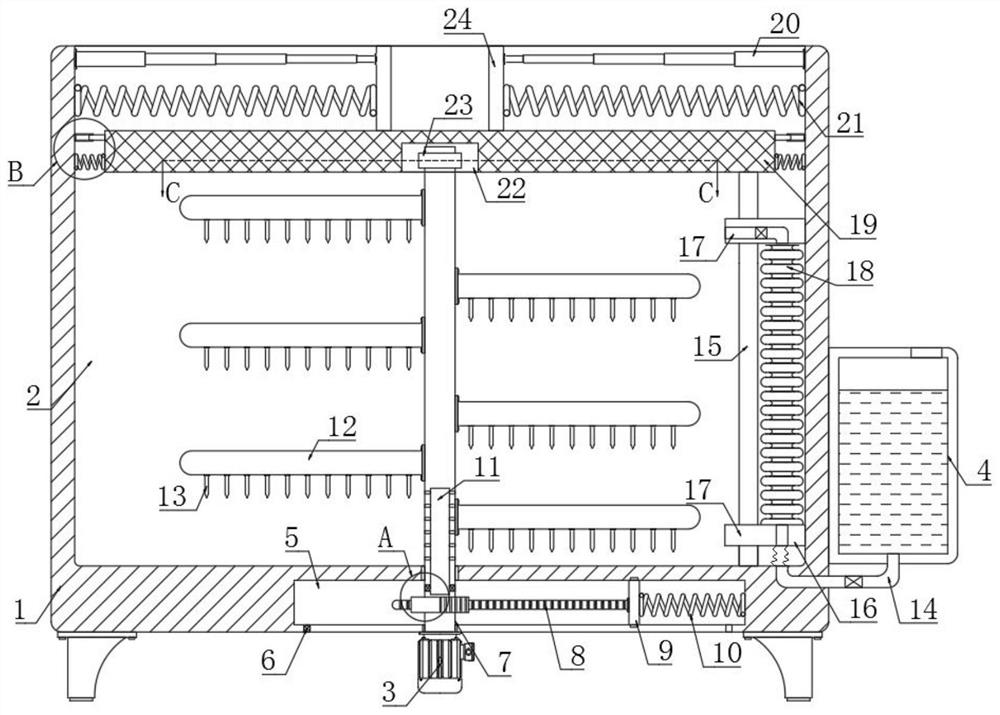

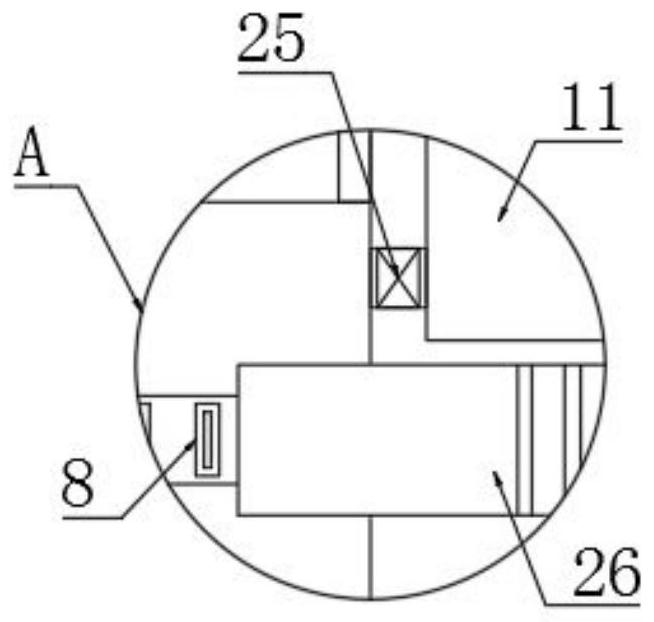

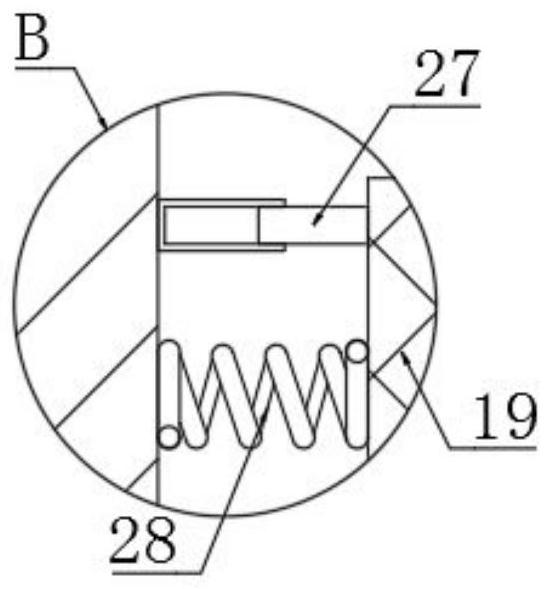

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

[0023] refer to Figure 1-5 , a sedimentation tank for high-efficiency and environmentally friendly sewage treatment, comprising a shell 1, the upper end of the shell 1 is provided with a sedimentation tank 2, the lower end of the shell 1 is installed with a stirring motor 3, and the end of the output shaft of the stirring motor 3 extends to the sedimentation tank 2 A rotating rod 7 is fixedly connected inside, the outer wall of the rotating rod 7 is provided with a plurality of stirring rods 12 along its axial direction, and the lower end of each stirring rod 12 is provided with a plurality of thorns 13. There are telescopic plates 27 on both sides, and the telescopic ends of the two telescopic plates 27 are fixedly connected with a filter screen 19. The left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com