Digital image measuring method and equipment of triaxle testing sample soil deformation

A digital image, triaxial test technology, applied in electrical digital data processing, soil material testing, material inspection and other directions, can solve the problems of difficult operation, complicated test process, soil sample volume deformation, etc., to reduce labor intensity, Achieve the effect of test identification and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

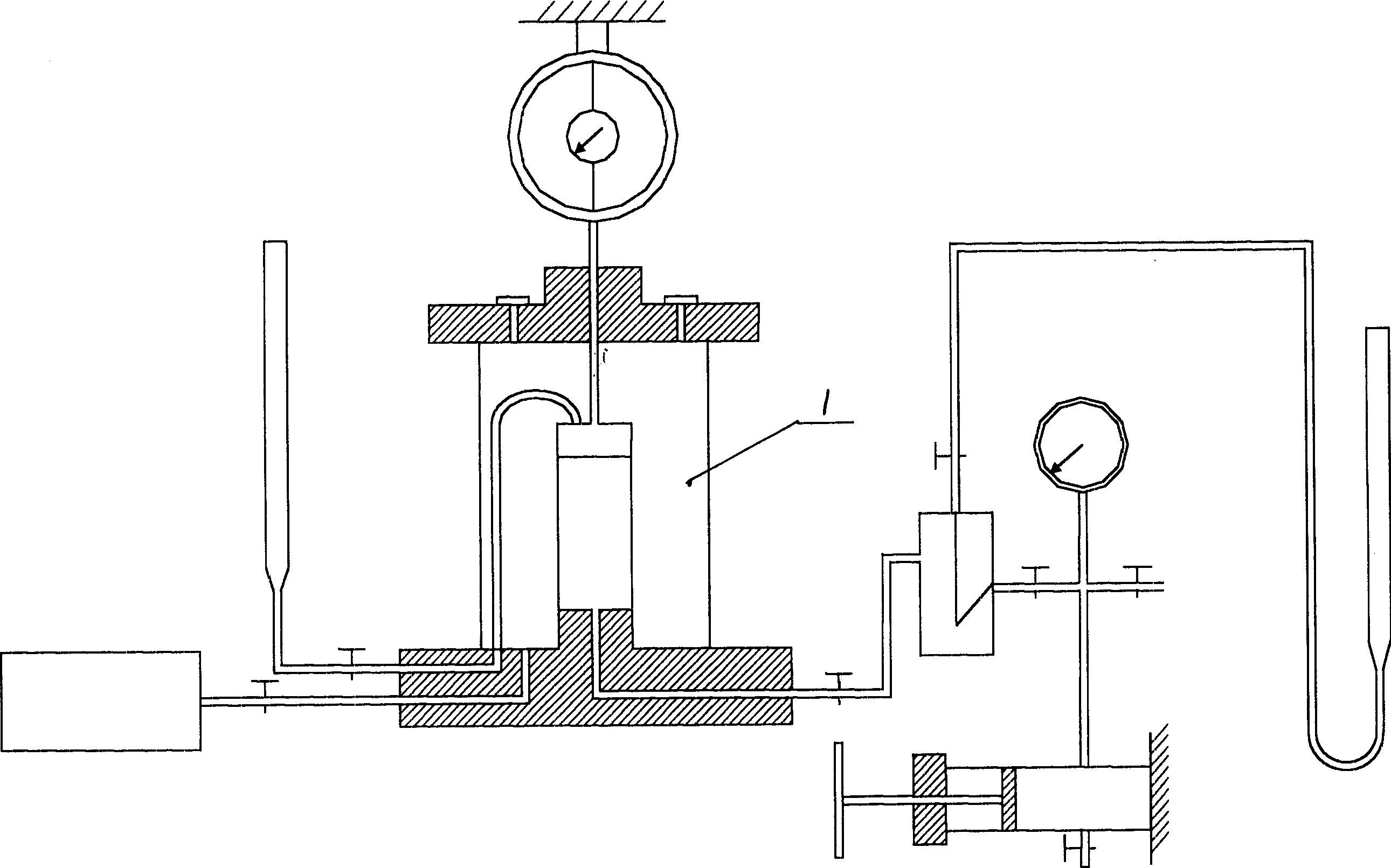

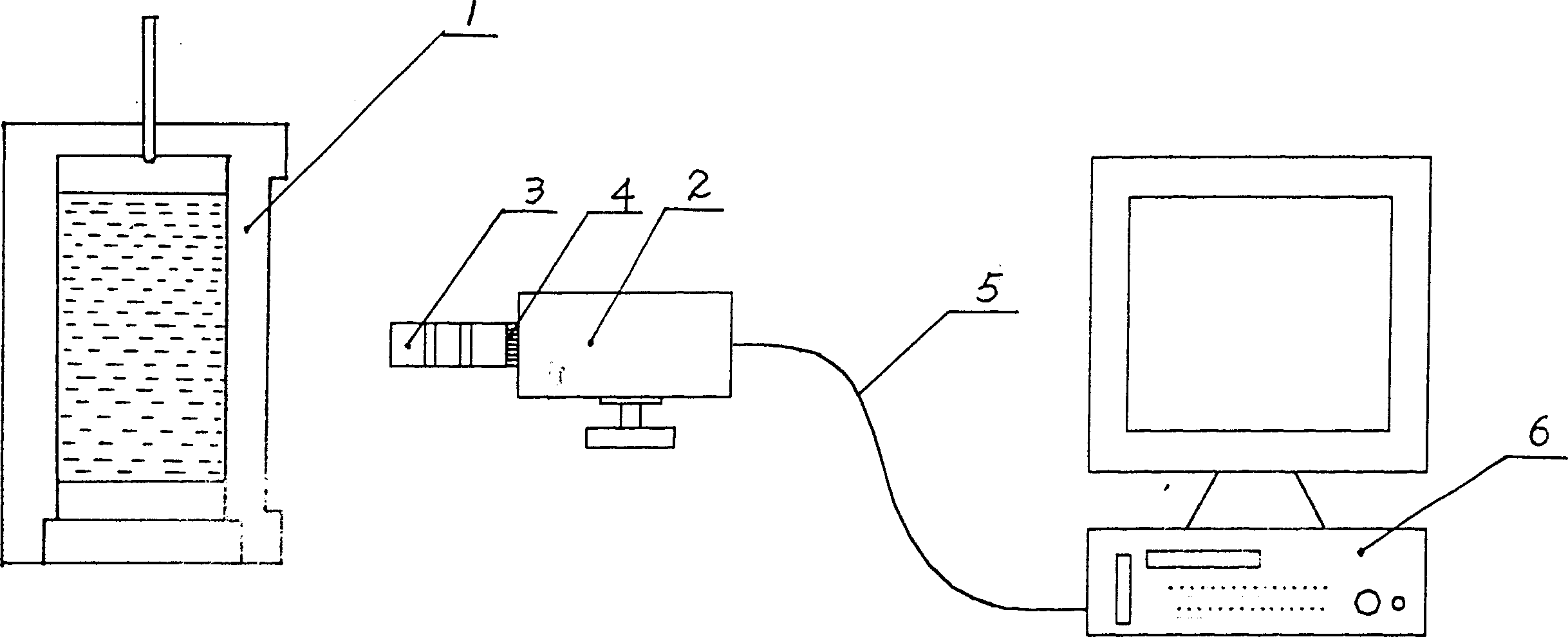

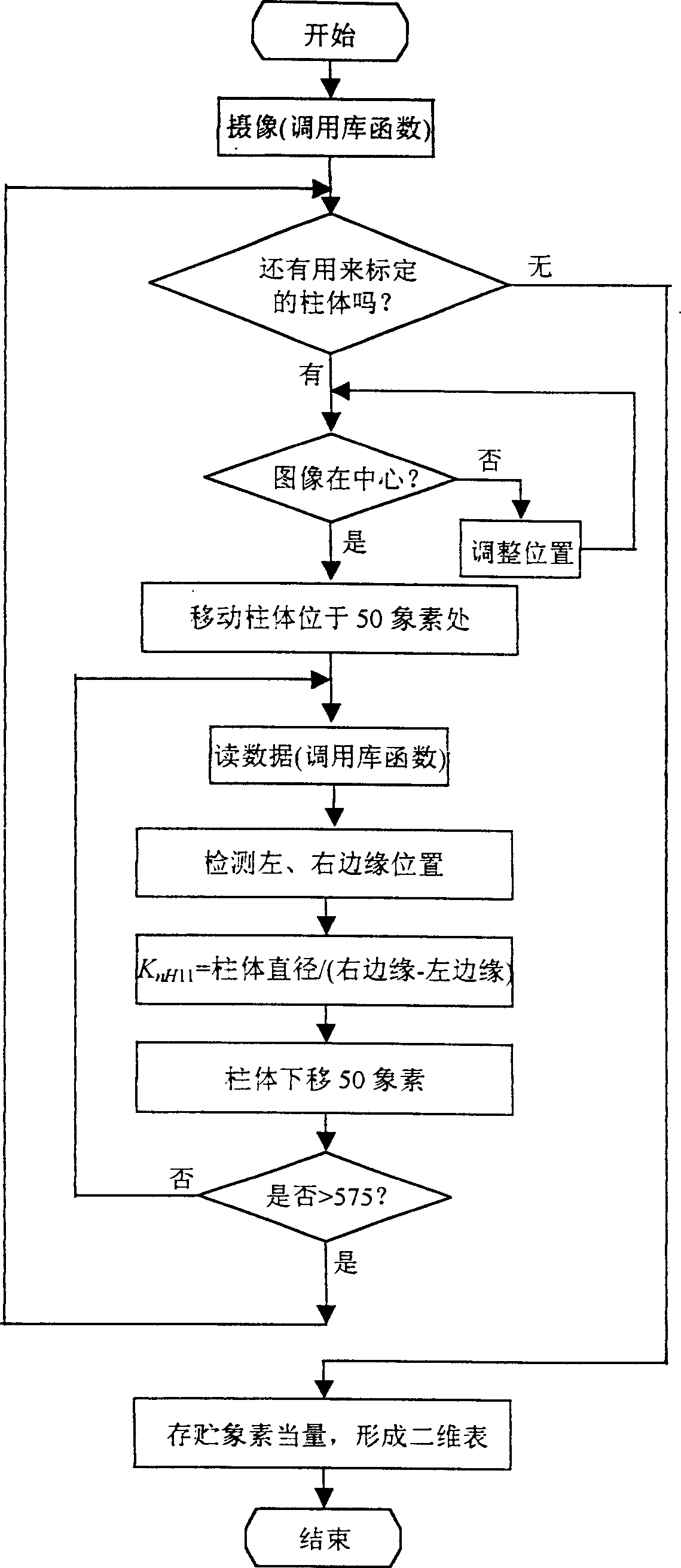

[0023] Digital image measurement equipment for soil sample deformation in triaxial tests, such as figure 2 As shown, it consists of a three-axis compressor, a digital image acquisition device and a microcomputer. The sealed cover of the triaxial compressor is a transparent tempered glass square sealed container 1, and the standard diameter and length are set on the base; the digital image acquisition equipment is composed of a charge-coupled device 2, a focusing lens 3 and a magnifying lens 4. The front end of the charge-coupled device 2 is composed of Connect the magnifying lens 4 and the focusing lens 3; the microcomputer 6 is equipped with a video capture card and a display card, and the data transmission line 5 of the charge-coupled device is connected to the video capture card. The program is divided into two parts: the first part is the calibration of the pixel equivalent, and the second part is the triaxial specimen deformation measurement. Each part is composed of tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com