Stable circular knitting machine base

A kind of large circular knitting machine, stable technology, applied in mechanical equipment, springs/shock absorbers, textiles and papermaking, etc., can solve the complex operation adjustment and fixation, can not be fixed, the position change of large circular knitting machine can not flexibly realize movement and positioning, etc. problem, to achieve good shock absorption and buffering effect, good position adjustment and fixation, and the effect of increasing positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

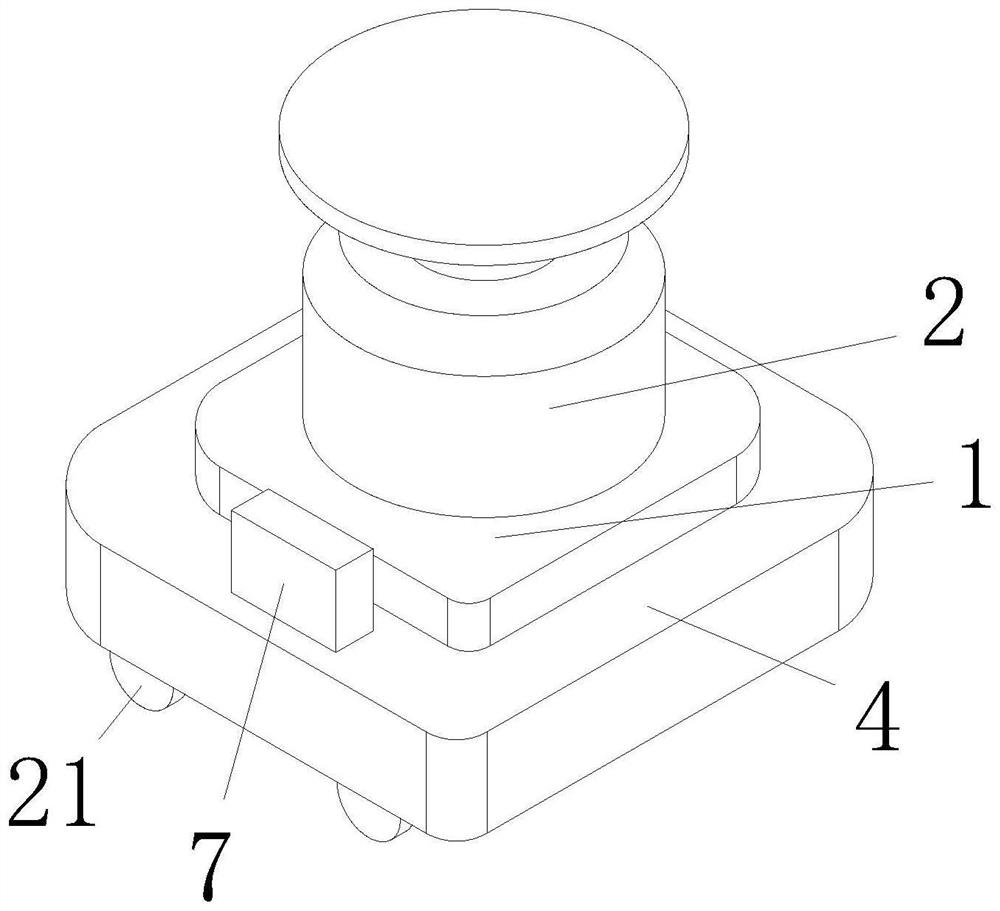

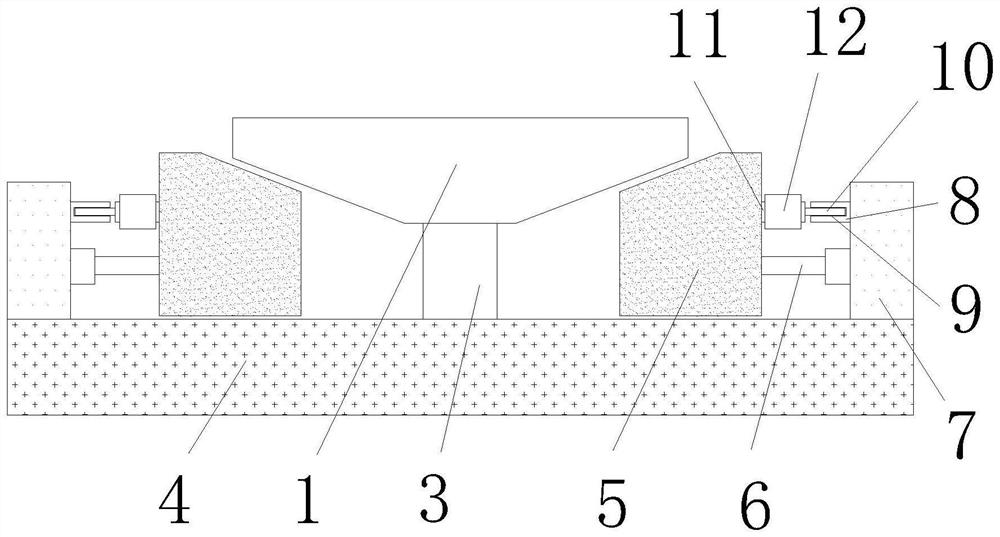

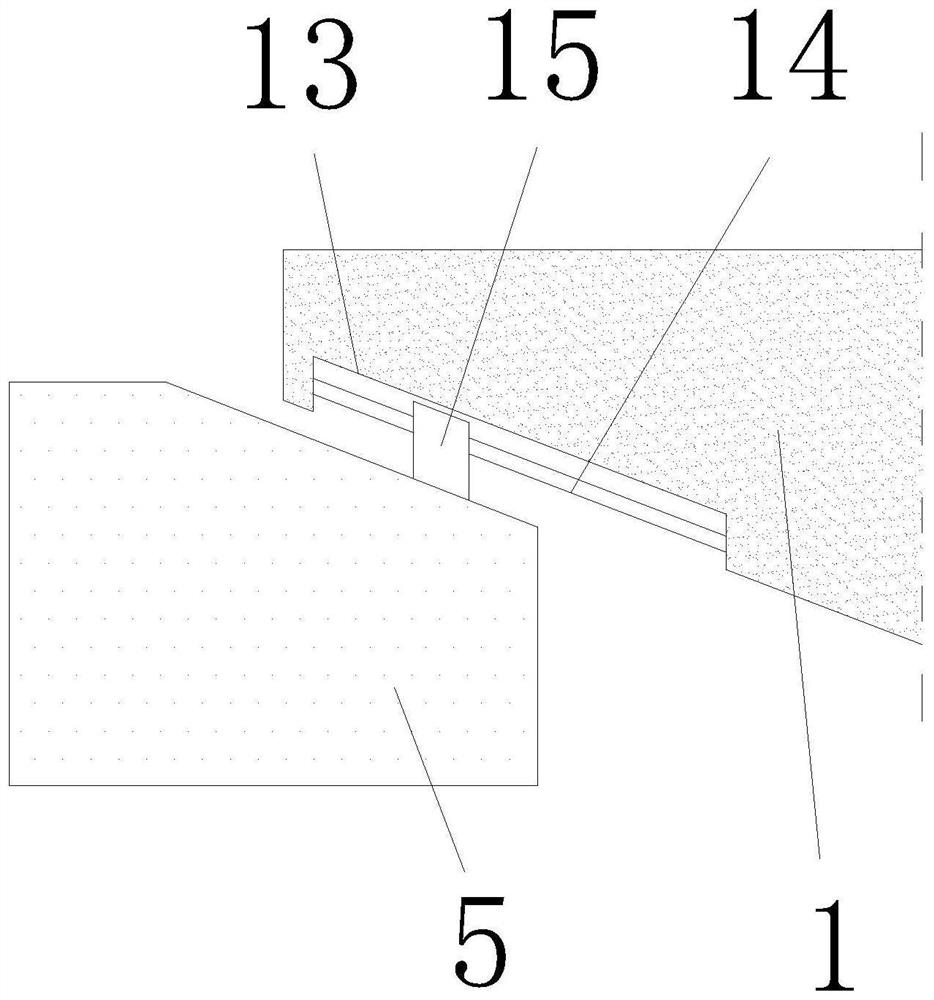

[0025] Example: a stable type large circular machine base, such as Figure 1-Figure 5As shown, a stable type large circular machine base, including the base plate 1, the upper side of the base plate 1 is fixed to the large circular machine 2, the bottom plate 1 is fixed to connect the finite position column 3, the lower end of the limit column 3 is sliding to connect the organic base 4, the upper side of the machine base 4 is sliding connected to the adjustment plate 5, the upper side of the adjustment plate 5 and the lower side of the base plate 1 are inclined, the right side of the adjustment plate 5 is fixed with a hydraulic telescopic rod 6, the right end of the hydraulic telescopic rod 6 is fixed to connect the auxiliary plate 7, and the lower side of the auxiliary plate 7 is fixed to the upper side of the base 4. The left fixed connection of the auxiliary plate 7 is connected to the first docking column 8, the inner side of the first docking column 8 is opened with a built-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com