Napping coating process applying water-based flashing paint

A technology using water-based and coating technology, applied in covering/lining, construction, building construction, etc., can solve the problems of short life, easy cracking, etc., achieve high aesthetics, improve adhesion, and improve the strength of the base surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

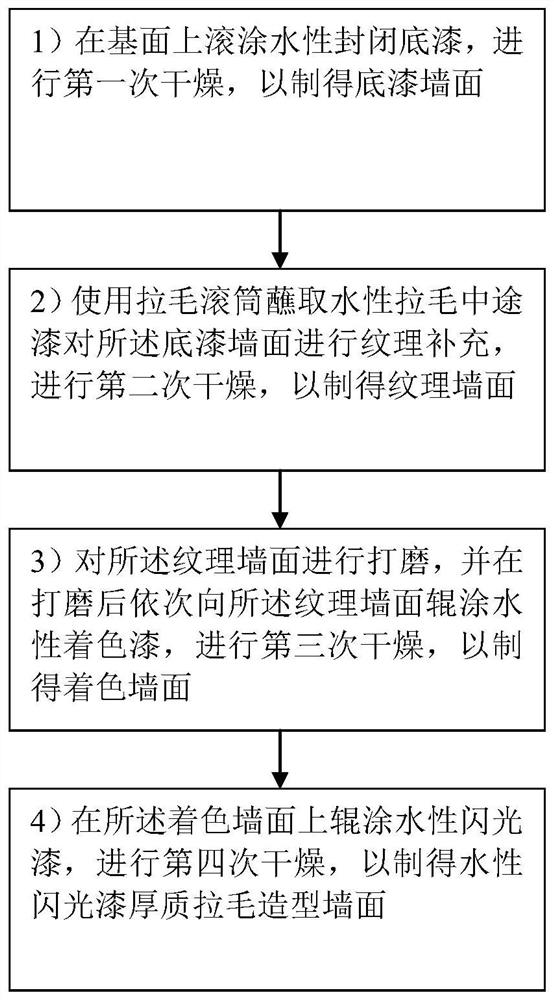

Method used

Image

Examples

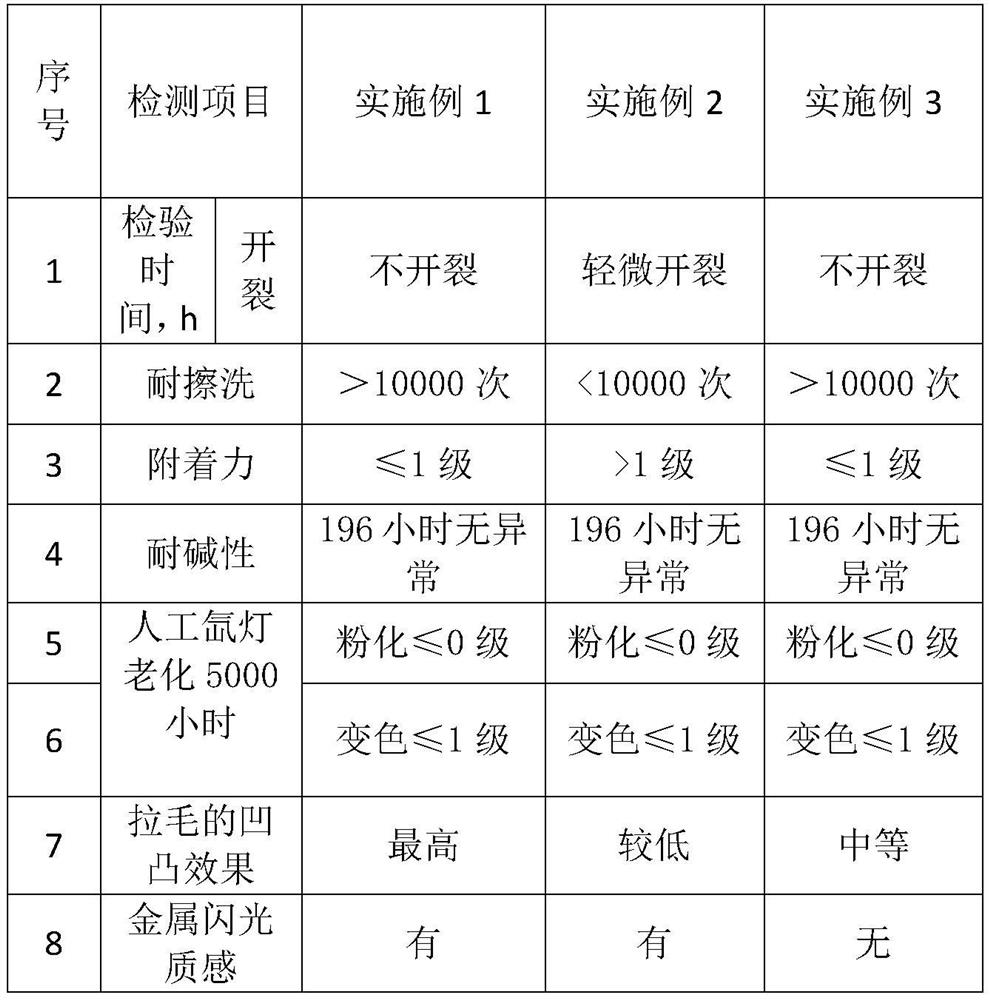

Embodiment 1

[0070] (1) Base surface treatment:

[0071] (1) Carefully check the flatness of the wall with a 2m long ruler, and mark the obvious concave and convex parts with a color pen;

[0072] (2) Repair: repair the parts with holes or obvious depressions with cement mortar first;

[0073] (3) Grinding: Use a sand mill to grind the obvious protruding parts and repaired parts to meet the requirements ≤ 2mm / 2m;

[0074] (4) Use brushes, shovels, trowels and water to remove wall adhesions and floating dust.

[0075] (2) Leveling plaster leveling

[0076] (1) A full batch of leveling plaster, with a thickness of about 1.5mm, after drying for 12 hours, a full batch of leveling plaster is added on it;

[0077] (2) Dry for 12 hours.

[0078] (3) Construction of flexible rough putty

[0079] (1) Full batch of flexible rough putty; after the first full batch of scraping, use a scraper to scrape from bottom to top, and after drying for 4 hours, carefully polish to remove scratches. After t...

Embodiment 2

[0100] The construction was carried out according to the method of Example 1, except that the water-based sealing primer used in Example 1 was not used to obtain Example 2.

Embodiment 3

[0102] The construction was carried out according to the method of Example 1, except that the water-based glitter paint used in Example 1 was not used to obtain Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com