Circuit breaker overload protection structure

An overload protection and circuit breaker technology, which is applied in the direction of protection switches, protection switch operation/release mechanisms, emergency protection devices, etc., can solve problems such as long reset time, high cost, failure of product overload protection characteristics, etc., and achieve high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

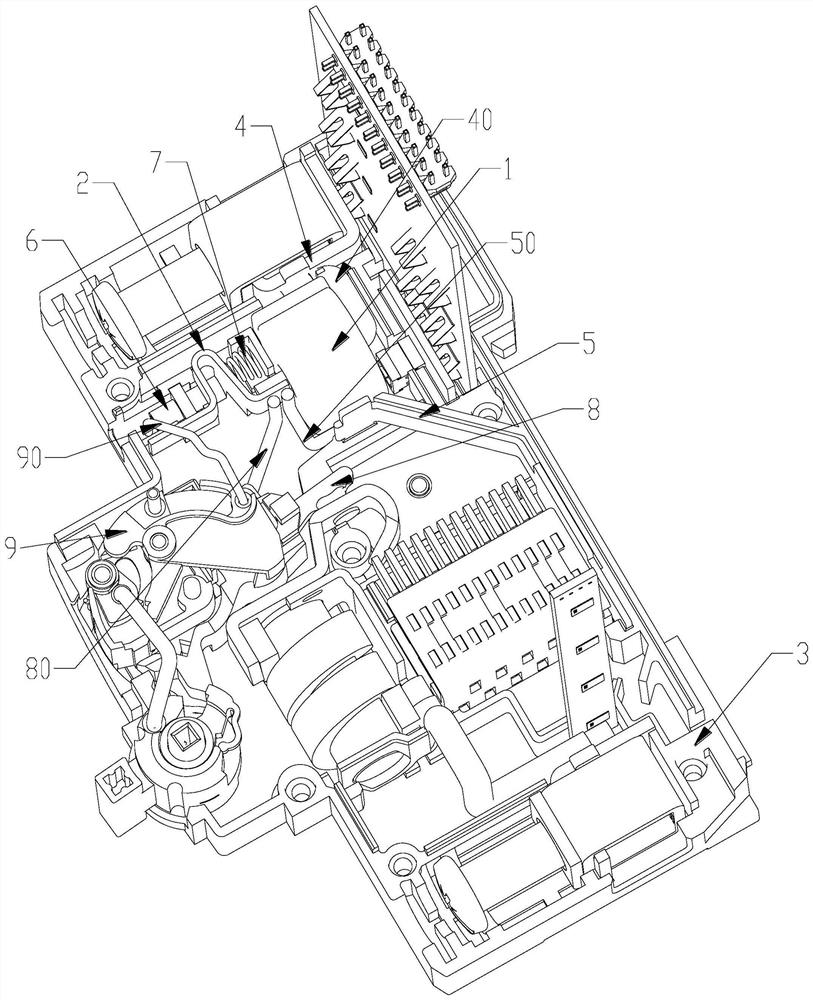

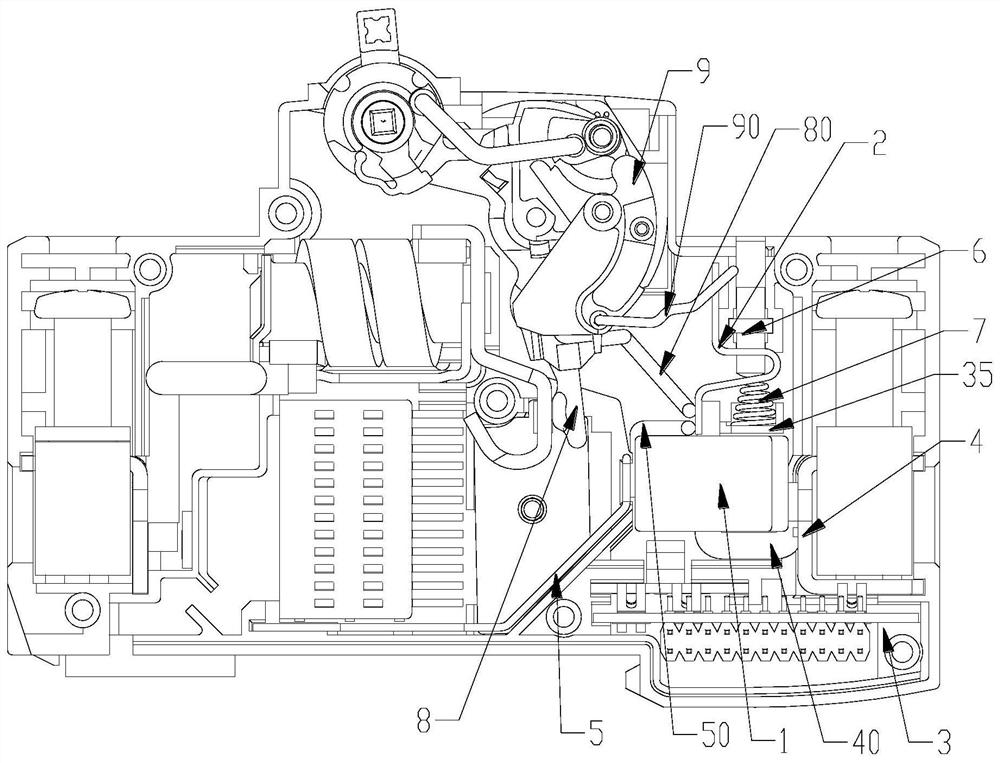

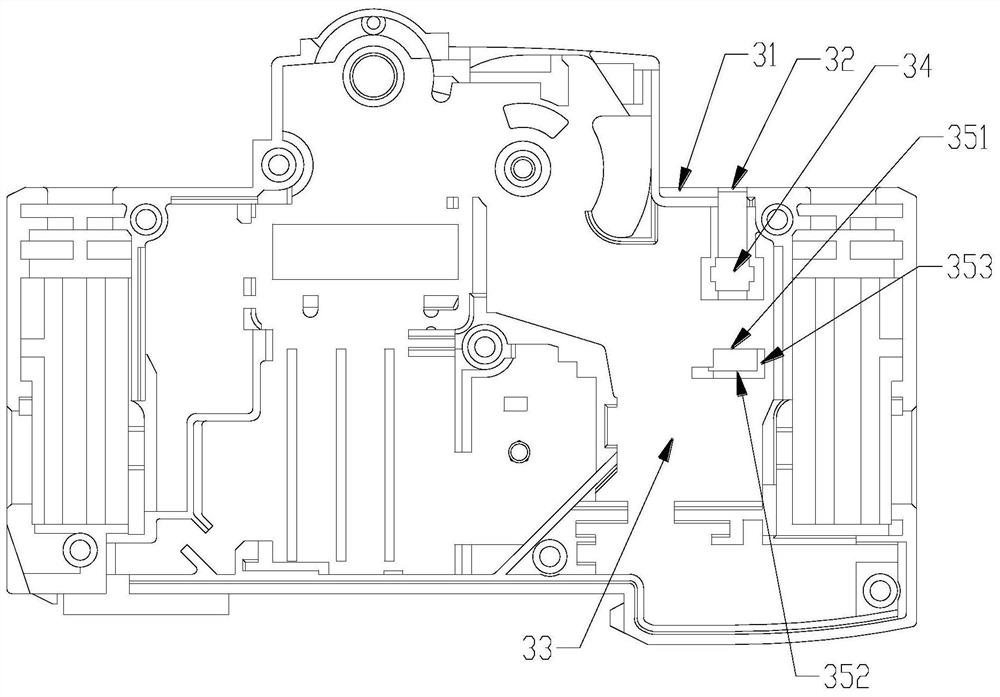

[0021] Attached to the following Figures 1 to 4 The given examples further illustrate the specific implementation of the circuit breaker overload protection structure of the present invention. The overload protection structure of the circuit breaker of the present invention is not limited to the description of the following embodiments.

[0022] like Figure 1-4 As shown, the circuit breaker overload protection structure of the present invention includes a current transformer 1 installed in the base 3, a bimetallic sheet 2, a hard wire 40, a wiring board 4, an arc striking board 5, an adjusting screw 6, a return spring 7 and The movable contact 8 and the lock 9 of the operating mechanism, one end of the bimetal 2 is the bendable portion 21 that is drivingly connected with the lock 9 of the operating mechanism, the other end of the bimetal 2 is the connecting portion 25, the hard wire 40 One end is connected to the wiring board 4, the other end of the hard wire 40 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com