Office building corridor security camera

A technology for cameras and office buildings, used in image communication, cleaning methods using liquids, televisions, etc., can solve problems such as manual cleaning, security cameras cannot be cleaned, and no protective components, etc., to achieve the effect of strengthening the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

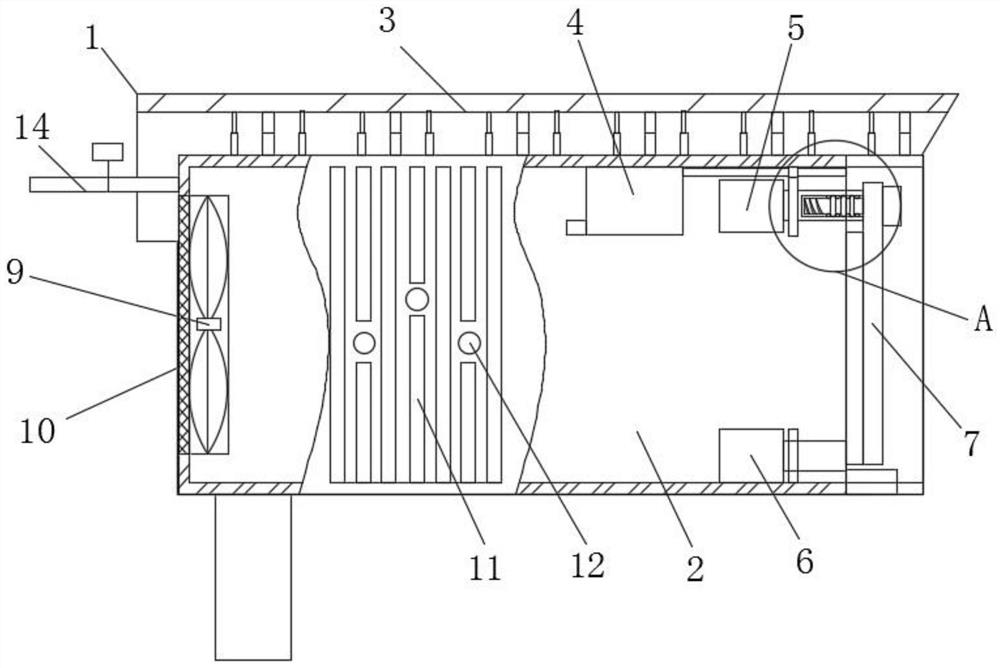

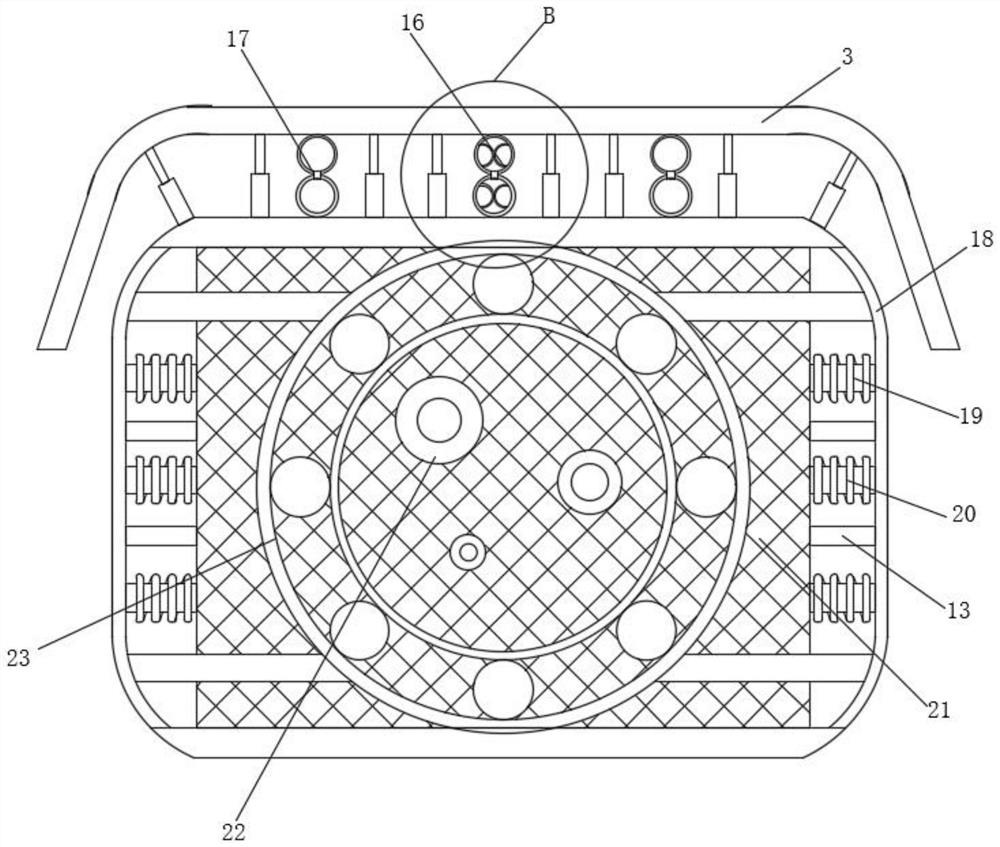

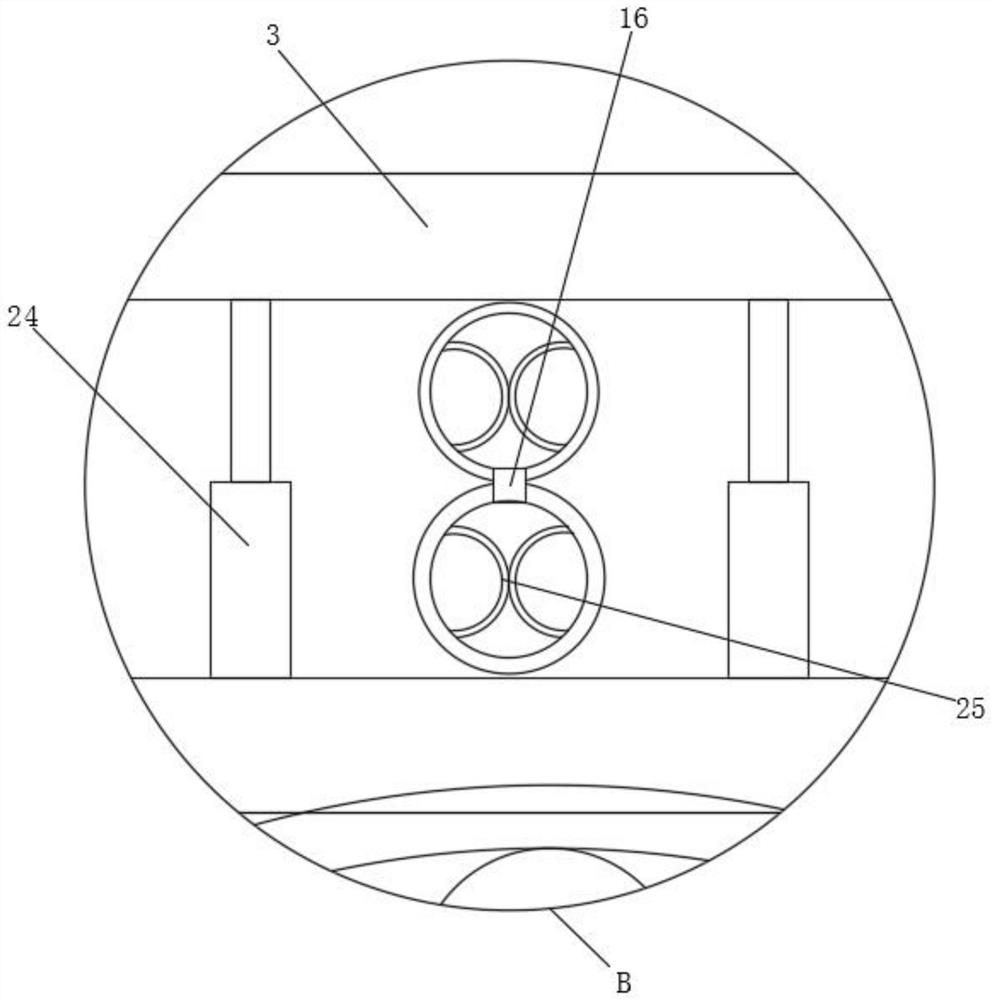

[0039] like Figure 1-8As shown, the present invention provides an office building corridor security camera, including a main device 1, a camera 2 is arranged inside the main device 1, an external protective shell 3 is arranged on the upper surface of the camera 2, and a front surface is arranged on the front of the camera 2. A protective net 21 is placed, one side of the front protective net 21 is fixedly connected with a lateral protective net 18, the inner wall of the lateral protective net 18 is fixedly connected with a first buffer spring 19, and a second buffer is arranged below the first buffer spring 19. For the spring 20 , the top of the inner wall of the outer protective shell 3 is fixedly connected with a first buffer composite elastic piece 16 , and the inner wall of the first buffer composite elastic piece 16 is fixedly connected with a supporting arc elastic piece 25 .

[0040] When the outer wall of the camera 2 is impacted, the side protection net 18 transmits ...

Embodiment 2

[0045] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner wall of the rotating installation cylinder 27 is fixedly connected with the installation limit elastic piece 28, and the outer wall of the left end of the rotating installation block 30 is fixedly connected with a rubber resistance ring. 29. The outer wall of the rubber baffle ring 29 is movably connected to the outer wall of the installation limit elastic piece 28, the inner wall of the first cleaning brush plate 7 is movably connected with a bristle plate 31, and the left inner wall of the first cleaning brush plate 7 is fixedly connected with a fixed magnet block. 40. A moving magnet block 41 is movably connected to the right side of the fixed magnet block 40. The right side of the moving magnet block 41 is fixedly connected to the left end of the bristle plate 31, and the inner wall of the right end of the first cleaning brush plate 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com