Sliding arc discharge plasma generation system

A technology of discharging plasma and generating system, applied in the field of plasma energy conversion, can solve the problems of poor selectivity and low efficiency of plasma power supply, and achieve the effect of improving selectivity and promoting conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the examples, but the present invention is not limited to these examples.

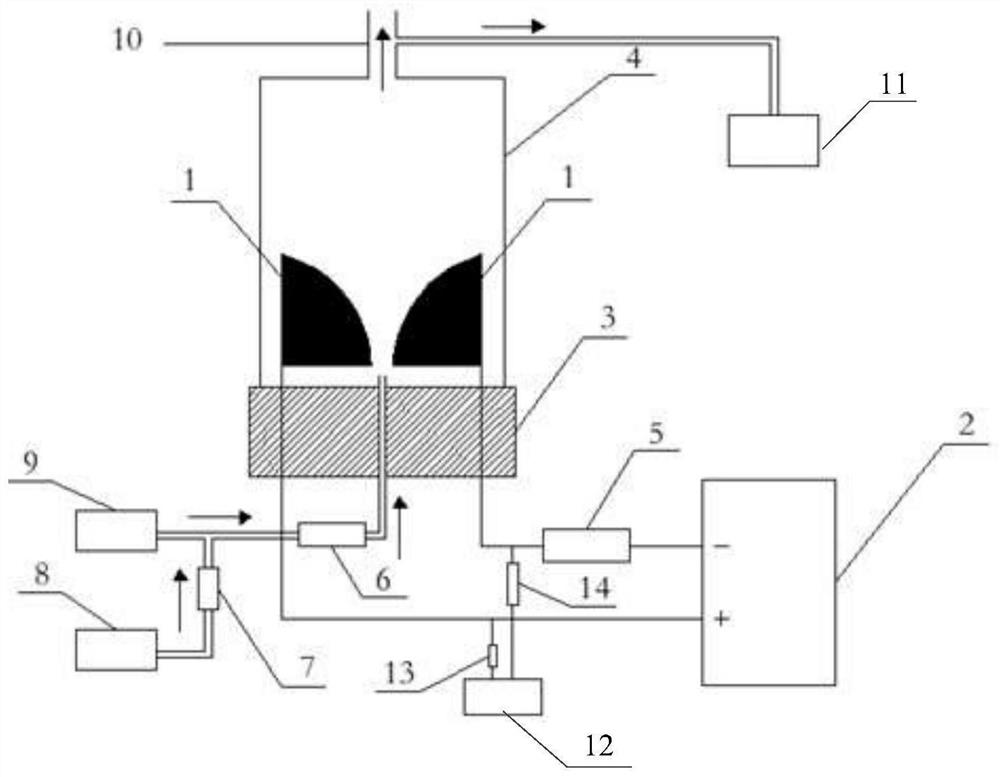

[0021] The embodiment of the present invention provides a gliding arc discharge plasma generation system, such as figure 1 As shown, the system includes: a discharge device, the discharge device includes an insulating base 3, a cover body 4 arranged on the insulating base 3, and two blade-shaped electrodes 1 arranged in the cover body 4; two blade-shaped electrodes 1 Both have arc-shaped sides, and the arc-shaped sides of the two blade-shaped electrodes 1 are arranged opposite to each other; the gas distribution device is used to transport the mixed gas of air and fuel gas to the area between the two blade-shaped electrodes 1 through the insulating base 3; The constant current AC power supply 2 is used to supply power to the two blade-shaped electrodes 1 to generate sliding arc plasma in the cover 4; the discharge frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com