Liquid supply type screw compressor

A screw compressor and liquid supply technology, which is applied to liquid fuel engines, rotary piston machinery, mechanical equipment, etc., can solve the problems of screw compressor power loss and pressure rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

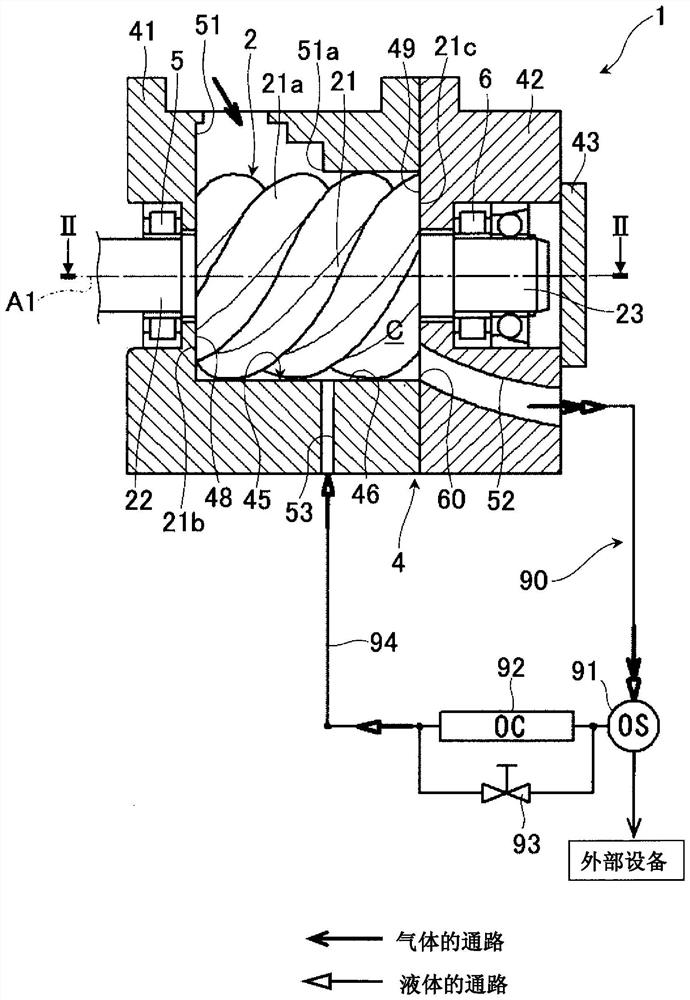

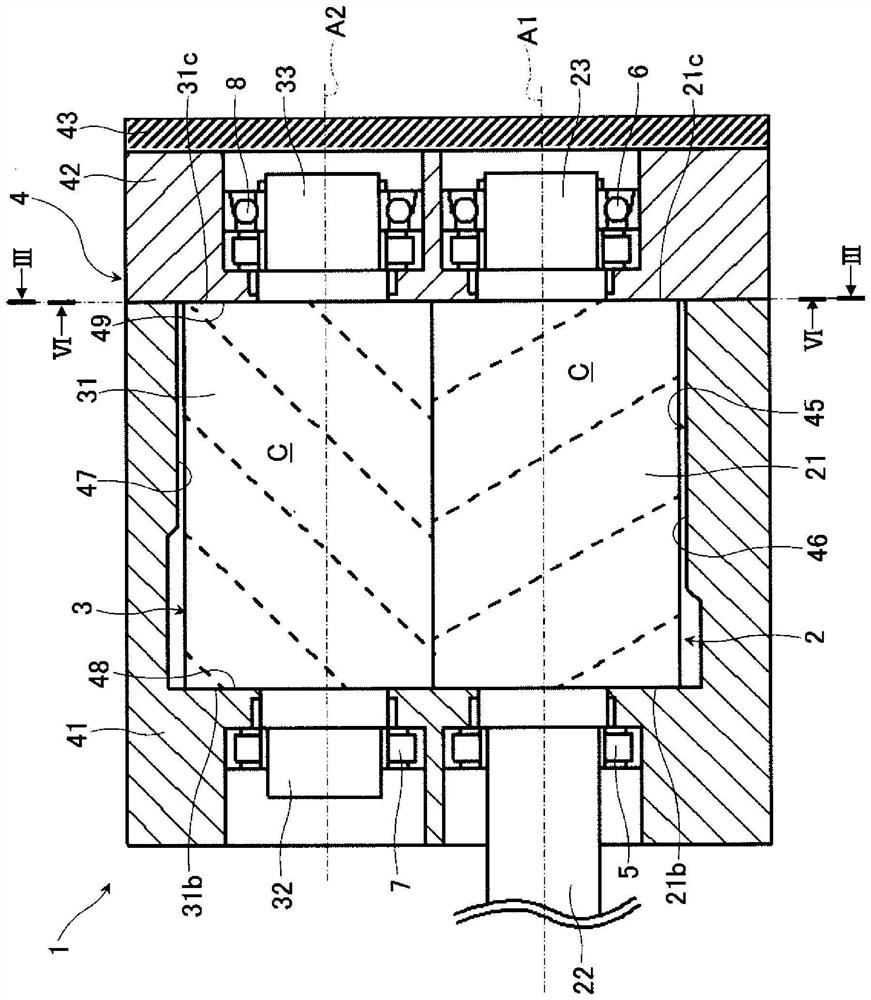

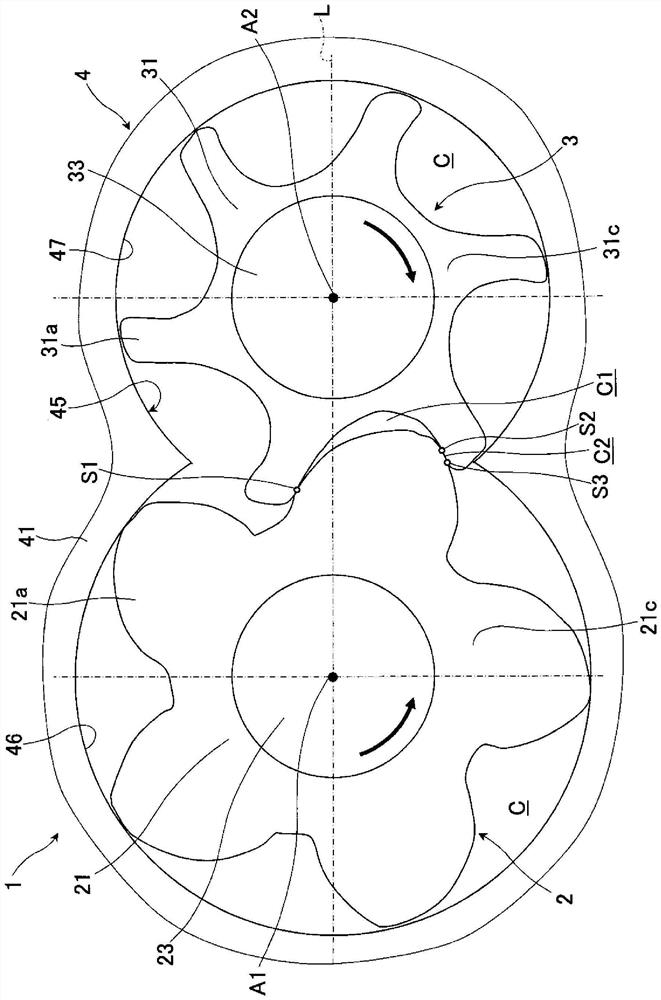

[0036] use Figure 1 and Figure 2 Describes the structure and action of the first embodiment of the liquid-supply screw compressor. Figure 1 is a cross-sectional view of a liquid supply screw compressor representing a first embodiment of the present invention and a system diagram illustrating the external path of the liquid supply screw compressor. Figure 2 is from Figure 1 The II-II shown looks at the cross-sectional view of the first embodiment of the present invention in the liquid-supply screw compressor. Figure 2 is from Figure 1 The II-II shown looks at the cross-sectional view of the first embodiment of the present invention in the liquid-supply screw compressor. Figure 1 and Figure 2 In the middle, the left side is the suction side of the liquid-supply screw compressor, and the right side is the discharge side. Figure 2 , the dotted line shows that it appears on the bottom side of the yang and yin rotors ( Figure 1 The top line of the tooth on the lower side).

[0037] Fig...

no. 2 approach

[0094] Subsequently, for the second embodiment of the liquid supply screw compressor is used Figure 15 Example description. Figure 15 is an enlarged view of the axial discharge outlet in a liquid-supply screw compressor representing a second embodiment of the present invention. Other than that Figure 15 Medium, and Figures 1 to 14 The part of the same symbol shown in the symbol is the same part, so its detailed description is omitted.

[0095] Figure 15 The second embodiment shown in the liquid supply screw compressor and the first embodiment of the liquid supply screw compressor (reference Figure 7 The difference is that a structure is adopted so that the axial discharge outlet 60A of the second slot 63A extends only from the first slot 62 to the midway position of the first contour line 71. Specifically, the second slot portion 63A is the same as the first embodiment, one side end is connected to the connection position 64 of the first slot portion 62. On the other hand, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com