Ceramic cloisonne enamel manufacturing method

A production method and ceramic technology, applied in ceramic forming machines, manufacturing tools, special decorative structures, etc., can solve problems such as falling off of silver wire patterns, affecting the firing of enamel glaze, affecting the aesthetics, etc., to achieve a smooth and even surface. The effect of reducing the probability of falling off and improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

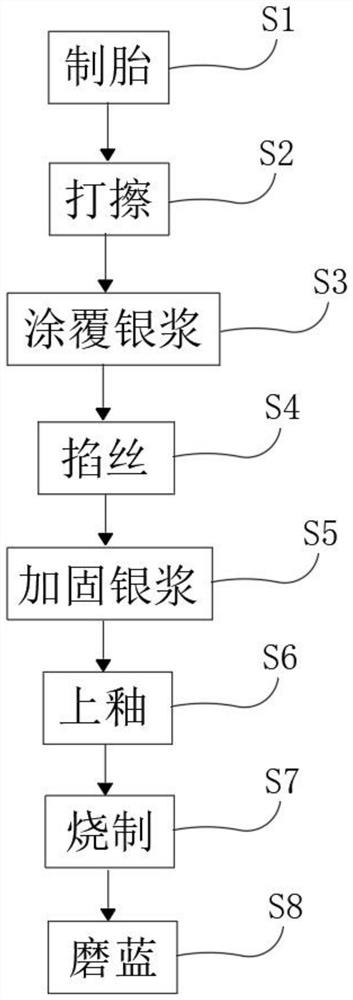

[0033] see figure 1 , a method for making ceramic cloisonné enamel, the method for making ceramic cloisonné enamel comprising the following steps:

[0034] S1, making tires, firstly prepare the good ceramics, and make the ceramics into a ceramic matrix;

[0035] S2, rubbing, the ceramic matrix obtained in the above-mentioned S1 step is polished with sandpaper, and the polishing time is 20min, until the surface of the ceramic matrix is smooth;

[0036] S3, coating silver paste, then uniformly coating a layer of high temperature sintered silver paste on the surface of the ceramic matrix, and then sintering to form a tight metallic silver layer on the surface of the ceramic matrix;

[0037] S4, filigree, then the silver wire is made into a pattern, and then the silver wire is bonded to the ceramic matrix by glue, and the operation of bonding the silver wire is completed at this time;

[0038] S5, strengthen the silver paste, and then coat a layer of high-temperature sintered ...

Embodiment 2

[0056] see figure 1 , a method for making ceramic cloisonné enamel, the method for making ceramic cloisonné enamel comprising the following steps:

[0057] S1, making tires, firstly prepare the good ceramics, and make the ceramics into a ceramic matrix;

[0058] S2, rubbing, the ceramic matrix obtained in the above-mentioned S1 step is polished with sandpaper, and the polishing time is 20-30min, until the surface of the ceramic matrix is smooth;

[0059] S3, coating silver paste, then uniformly coating a layer of high temperature sintered silver paste on the surface of the ceramic matrix, and then sintering to form a tight metallic silver layer on the surface of the ceramic matrix;

[0060] S4, filigree, then the silver wire is made into a pattern, and then the silver wire is bonded to the ceramic matrix by glue, and the operation of bonding the silver wire is completed at this time;

[0061] S5, strengthen the silver paste, and then coat a layer of high-temperature sinter...

Embodiment 3

[0079] see figure 1 , a method for making ceramic cloisonné enamel, the method for making ceramic cloisonné enamel comprising the following steps:

[0080] S1, making tires, firstly prepare the good ceramics, and make the ceramics into a ceramic matrix;

[0081] S2, rubbing, the ceramic matrix obtained in the above-mentioned S1 step is polished with sandpaper, and the polishing time is 25min, until the surface of the ceramic matrix is smooth;

[0082] S3, coating silver paste, then uniformly coating a layer of high temperature sintered silver paste on the surface of the ceramic matrix, and then sintering to form a tight metallic silver layer on the surface of the ceramic matrix;

[0083] S4, filigree, then the silver wire is made into a pattern, and then the silver wire is bonded to the ceramic matrix by glue, and the operation of bonding the silver wire is completed at this time;

[0084] S5, strengthen the silver paste, and then coat a layer of high-temperature sintered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com