Safe flame-retardant acrylic plate and preparation method thereof

An acrylic board and flame retardant technology, which is applied in the field of safe flame retardant acrylic board and its preparation, can solve the problems of poor flame retardant performance of acrylic board and mold growth of acrylic board, and achieves the improvement of light transmittance and improvement of mold growth. Effect

Pending Publication Date: 2022-06-10

李秋月

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the flame retardant performance of acrylic boards is relatively poor, and it is necessary to add flame retardants to the raw material formula to improve its flame retardant performance. At the same time, with the wide application of acrylic boards, many users will use them in wet areas such as bathrooms. Acrylic boards, which in turn cause acrylic boards to easily breed mold due to moisture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0038] S6, finally, after the surface of the plate is hardened, inject cold water and cool down to 30 ° C, and demould, that is, an acrylic plate.

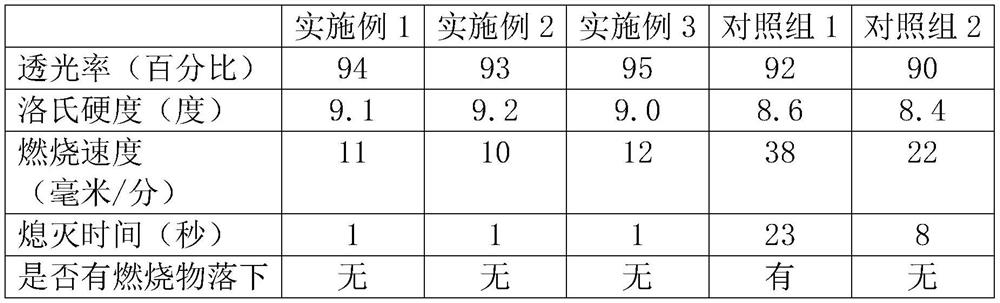

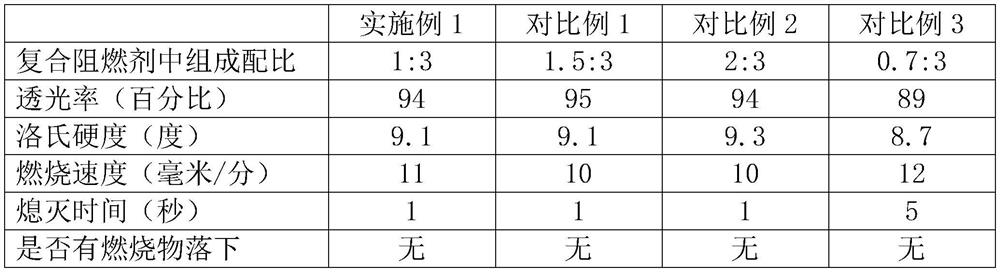

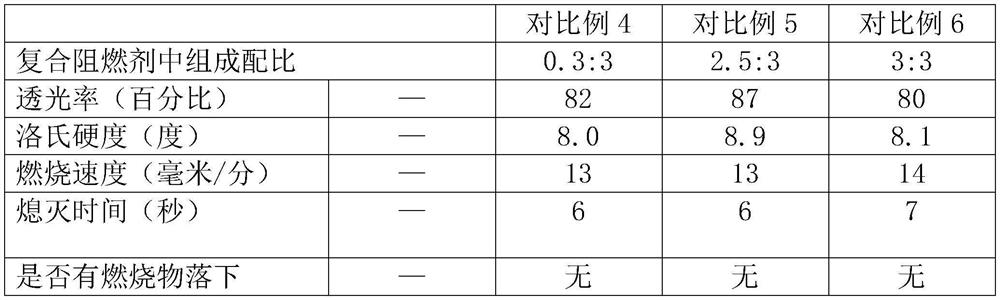

[0043]

[0047] As can be seen, the acrylic sheet in the embodiment 1-3 possesses good flame retardant properties. Therefore, the acrylic of the present invention

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of acrylic plate manufacturing, in particular to a safe flame-retardant acrylic plate and a preparation method thereof. Each acrylic plate is prepared from the following raw materials: 100 to 300 parts of polymethyl methacrylate, 1 to 2 parts of an initiator, 8 to 16 parts of a composite flame retardant, 8 to 12 parts of p-xylene dioctyl ester, 7 to 9 parts of carboxymethyl cellulose, 7 to 9 parts of tetraethoxysilane, 1 to 2 parts of a release agent, 3 to 6 parts of a Boston fern extracting solution and 1 to 2 parts of eucalyptol. The preparation method of the acrylic plate comprises the following steps: S1, uniformly mixing polymethyl methacrylate and an initiator, adding the mixture into a reaction kettle, heating at the rotating speed of 60-75rpm until boiling, stopping heating, standing for 15-20 minutes, and cooling to room temperature to form a prepolymer; and S2, adding a release agent, p-xylene dioctyl ester and tetraethoxysilane into the prepolymer, uniformly mixing, and carrying out vacuum defoaming for later use. The acrylic plate disclosed by the invention has the flame retardant property, the light transmittance of the acrylic plate can also be improved, and mould bred in a humid environment can also be effectively inhibited.

Description

A kind of safe flame retardant acrylic sheet and preparation method thereof technical field The present invention relates to the technical field of acrylic sheet production, in particular to a kind of safety flame retardant acrylic sheet and preparation thereof method. Background technique Acrylic plate is a kind of thermoplastic organic macromolecule synthetic resin material is also three kinds of transparent plastics (PS, PC, One of PMMA). Acrylic sheets are more of a substitute for glass, and even have properties that glass does not have, such as high strength, not easy to break, resistant to Superior properties such as acid and alkali. Widely used in billboards, commercial display stands, decorations, doll machines, etc., and even in aerospace, water Family museums and museums are used. But the flame retardant performance of acrylic sheet is relatively poor, and it is necessary to improve its flame retardant by adding flame retardant to the raw material formu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L33/12C08L1/28C08K9/06C08K3/36C08K5/521C08K5/00C08K5/1545

CPCC08L33/12C08K2201/011C08L2201/02C08L1/286C08K9/06C08K3/36C08K5/521C08K5/0058C08K5/1545

Inventor 李秋月

Owner 李秋月

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com