Flue gas multi-component measurement system and use method

A measurement system, multi-component technology, applied in the direction of measurement device, gas analyzer structure details, analysis materials, etc., to reduce measurement errors, improve accuracy, and save installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

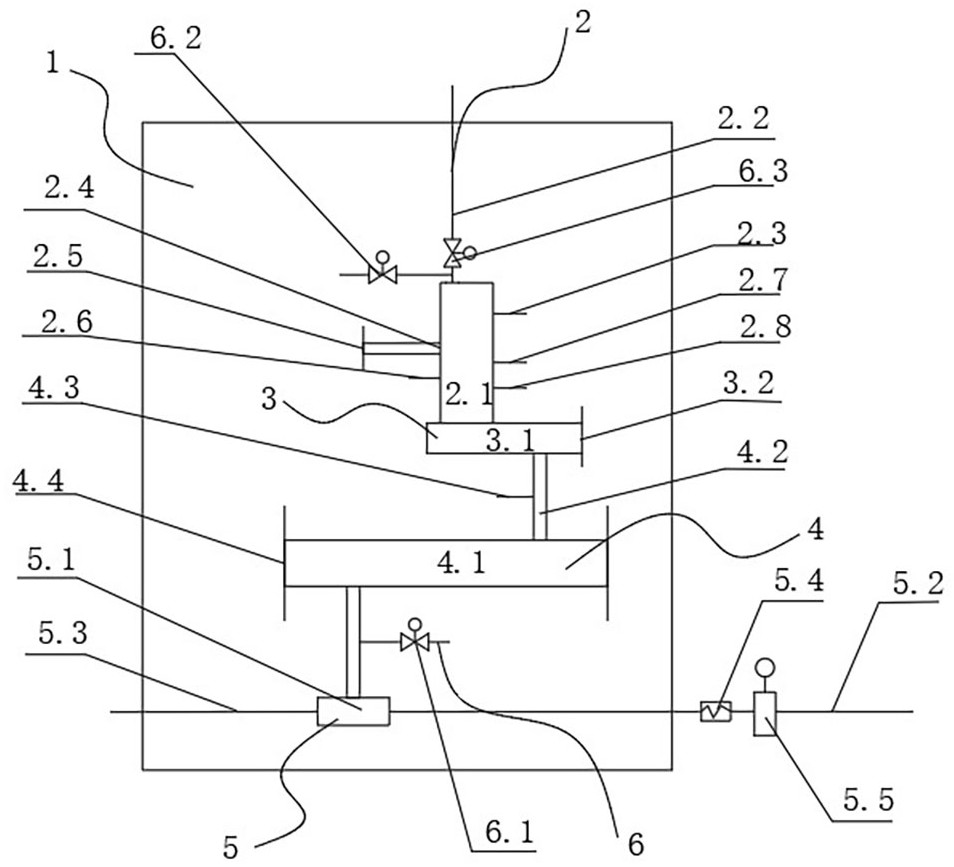

[0031] The wall thickness of the multi-component measuring cell 2.1 is not less than 2mm, and the pressure in the multi-component measuring cell 2.1 is kept between -3~-15kpa during flue gas measurement.

[0032] The measuring range of vacuum gauge 2.3 is -50kpa~1000kpa.

[0033] NO dilution probe interface 2.4 is suitable for various types of NO dilution probes, NO dilution method measurement interface flange 2.5 is suitable for various types of NO dilution method measuring instruments; NO direct extraction method measurement interface 2.6 is suitable for various types of NO direct Extraction measuring instrument; CO measuring interface 2.7 is suitable for various types of direct extraction CO analysis instruments; other component measuring interface 2.8 is suitable for various other component measuring instruments; oxygen measuring interface flange 3.2 is suitable for various types The zirconia measuring instrument, the extraction method ammonia measurement interface 11 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com