Rapid evaluation method for cycle performance of lithium iron phosphate battery negative electrode material

A technology of lithium iron phosphate battery and negative electrode material, which is applied in the direction of secondary battery, secondary battery repair/maintenance, secondary battery charging/discharging, etc., to achieve the effects of simple method, shortened evaluation period, easy operation and realization

Pending Publication Date: 2022-06-10

江苏海基新能源股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Taking a long-life energy storage battery as an example, it generally requires a cycle life of 3,000 to 6,000 times. Using the 1C charging and discharging system, it takes about 300 to 600 days to test the cycle life of 3,000 to 6,000 times. It can be seen that the traditional The method of evaluating negative electrode cycle performance is not only time-consuming and consumes a lot of energy, but also increases costs (including manpower, material resources and power consumption, etc.)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

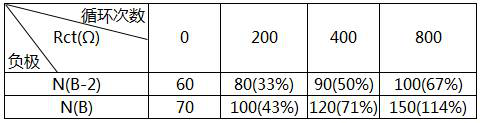

The invention relates to a rapid evaluation method for cycle performance of a lithium iron phosphate battery negative electrode material, which specifically comprises the following steps: (1) comparing normal-temperature 2C cycle performance and high-temperature 55DEG C 1C cycle performance of a standard battery and a to-be-tested battery, the difference between the to-be-tested battery and the standard battery is only that the negative electrode materials are different, a standard negative electrode material with qualified cycle performance is adopted in a standard battery B, and the cycle performance of the to-be-tested battery is not qualified; if the normal-temperature 2C cycle performance and the 1C cycle performance at the high temperature of 55 DEG C of the to-be-tested battery are superior to or equal to those of a standard battery B, the to-be-tested battery can be used as a substitute material of a standard negative electrode material, otherwise, the next operation is carried out; and (2) compared with the Rct growth rates of the negative electrodes of the two standard batteries and the battery to be tested in the normal-temperature 1C cycle process, the negative electrode material with the smaller Rct growth rate has better normal-temperature 1C cycle. The method is simple, rapid and easy to operate, and can be used for rapidly evaluating the negative electrode material.

Description

technical field [0001] The invention belongs to the technical field of lithium ion batteries, and in particular relates to a rapid evaluation method for the cycle performance of negative electrode materials of lithium iron phosphate batteries. Background technique [0002] Lithium-ion batteries have outstanding advantages such as high energy density, no memory effect, long cycle life, fast charging and discharging, and less self-discharge. Especially lithium iron phosphate batteries have long cycle life and safety, and are widely used in portable devices, electric vehicles, etc. Energy storage fields such as automobiles and aerospace have great market demand. [0003] General materials, manufacturing processes, tests, etc. will affect the cycle life of lithium iron phosphate batteries, and the negative electrode material has the greatest impact on its cycle life. The current method of evaluating the cycle performance of lithium iron phosphate battery anode materials is main...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R31/36G01R31/378G01R31/385G01R31/389H01M10/0525H01M10/44

CPCG01R31/36G01R31/378G01R31/385G01R31/389H01M10/0525H01M10/44

Inventor 居正伟葛科王化胜

Owner 江苏海基新能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com