Preparation method for producing wet-process konjac powder by ball milling method

A technology of konjac powder and ball milling method, which is applied in grain processing, etc., can solve the problems of low whiteness, low purity of konjac powder, large particle size, etc., and achieve good color, obvious color protection effect, and color improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

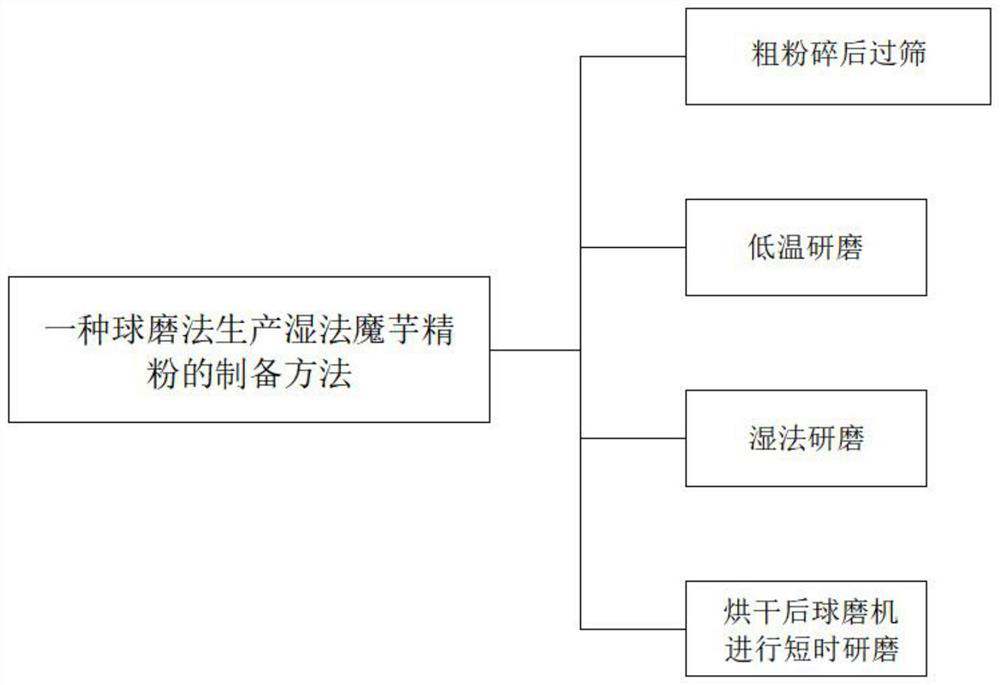

[0016] See Figure 1 , the present invention provides a technical solution: a ball mill method for producing wet konjac fine powder preparation method, comprising coarse crushing after sieve, low temperature grinding, wet grinding, drying after the ball mill for short grinding, the coarse crushing after sieving before the fresh konjac washed and peeled, sliced, color protection, dried at a temperature of 50 ° C, after drying completely, and then after coarse crushing after sieving.

[0017] Further, the ball mill method for producing wet konjac concentrate powder comprises the following steps:

[0018]Step 1, coarse crushing after sieving: the fresh konjac is washed and peeled, sliced, color protected, dried at a temperature of 50 ° C, after the drying is complete, then sieved after coarse crushing, and the coarse size of the konjac coarse powder is prepared;

[0019] Step 2, low temperature grinding: the konjac coarse powder is dried again until the moisture content is not more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com