Dacron weft elastic wavy crepe double-layer flannelette filling cloth

A flannel-filled and weft-elastic technology is applied in the field of polyester weft-elastic wave crepe double-layer flannel-filled fabrics, which can solve the problems of affecting wearing and easy generation of static electricity on the surface of the fabric, so as to improve adhesion, improve antistatic properties, and improve durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] The raw materials of the functional additive include the following components: 11kg of titanium dioxide, 8kg of ethoxyalkylamine antistatic agent, 6kg of acidified halloysite, 6kg of silane coupling agent, and 11kg of other additives. Among them, the silane coupling agent is γ-aminopropyltriethoxysilane.

[0037] The preparation raw materials of other auxiliary agents include the following components: 5kg of sodium dioctyl succinate sulfonate, 12kg of film-forming agent, and 4kg of film-forming auxiliary agent. Among them, the film-forming agent is oxidized paraffin. The film-forming aid is polyacrylic acid.

[0038] This preparation example also provides a preparation method of the functional additive, comprising the following steps:

[0039] Acidification of halloysite: The sulfuric acid solution and halloysite are mixed and reacted, and then the reaction product is washed to neutrality to obtain acidified halloysite. The sulfuric acid solution concentration was 2....

preparation example 2-10

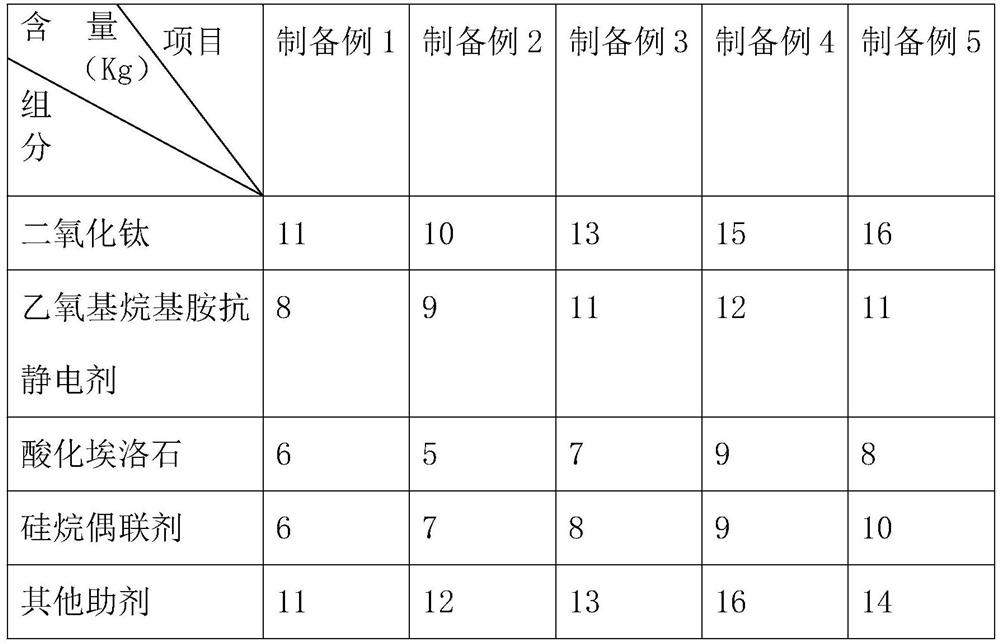

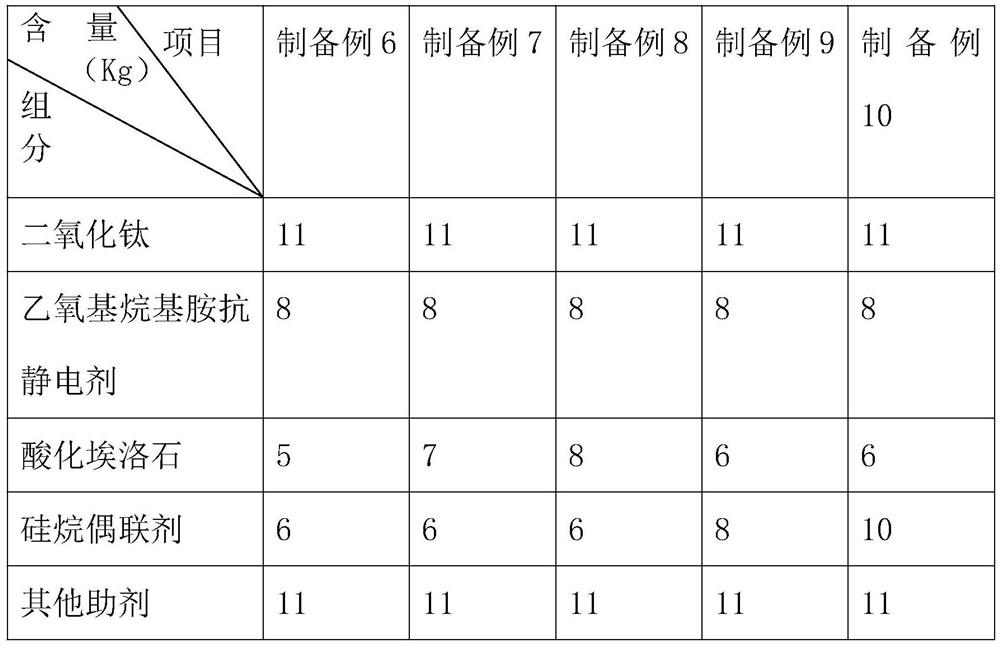

[0044] The difference between Preparation Example 2-10 and Preparation Example 1 is that the content of each component is different, see Table 1 and Table 2 for details.

[0045] Table 1

[0046]

[0047] Table 2

[0048]

preparation example 11-13

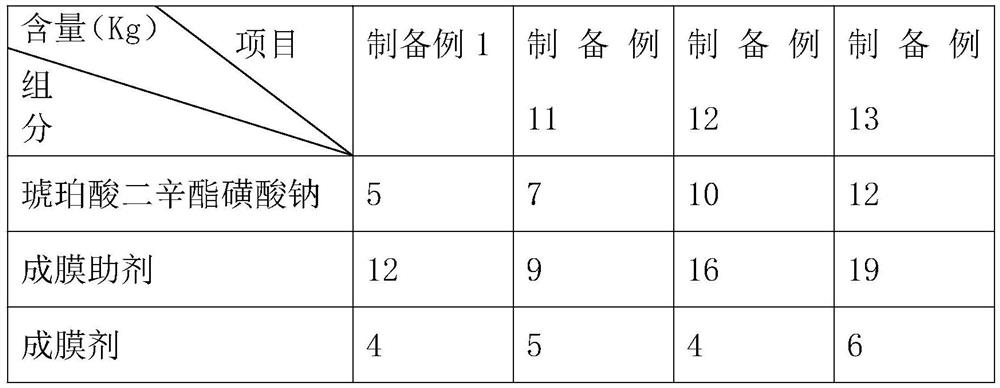

[0050] The difference between Preparation Examples 11-13 and Preparation Example 1 is that the raw materials of each component in other auxiliary agents are different, as shown in Table 3 for details.

[0051] table 3

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com