Novel material with antistatic and insulating properties and a preparation method thereof

An insulating and antistatic technology, applied in the direction of organic insulators, static electricity, insulators, etc., can solve the problems of low adhesion and easy falling off of antistatic cable insulation materials, and achieve the effect of inhibiting catalytic aging, not easy to fall off, and preventing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

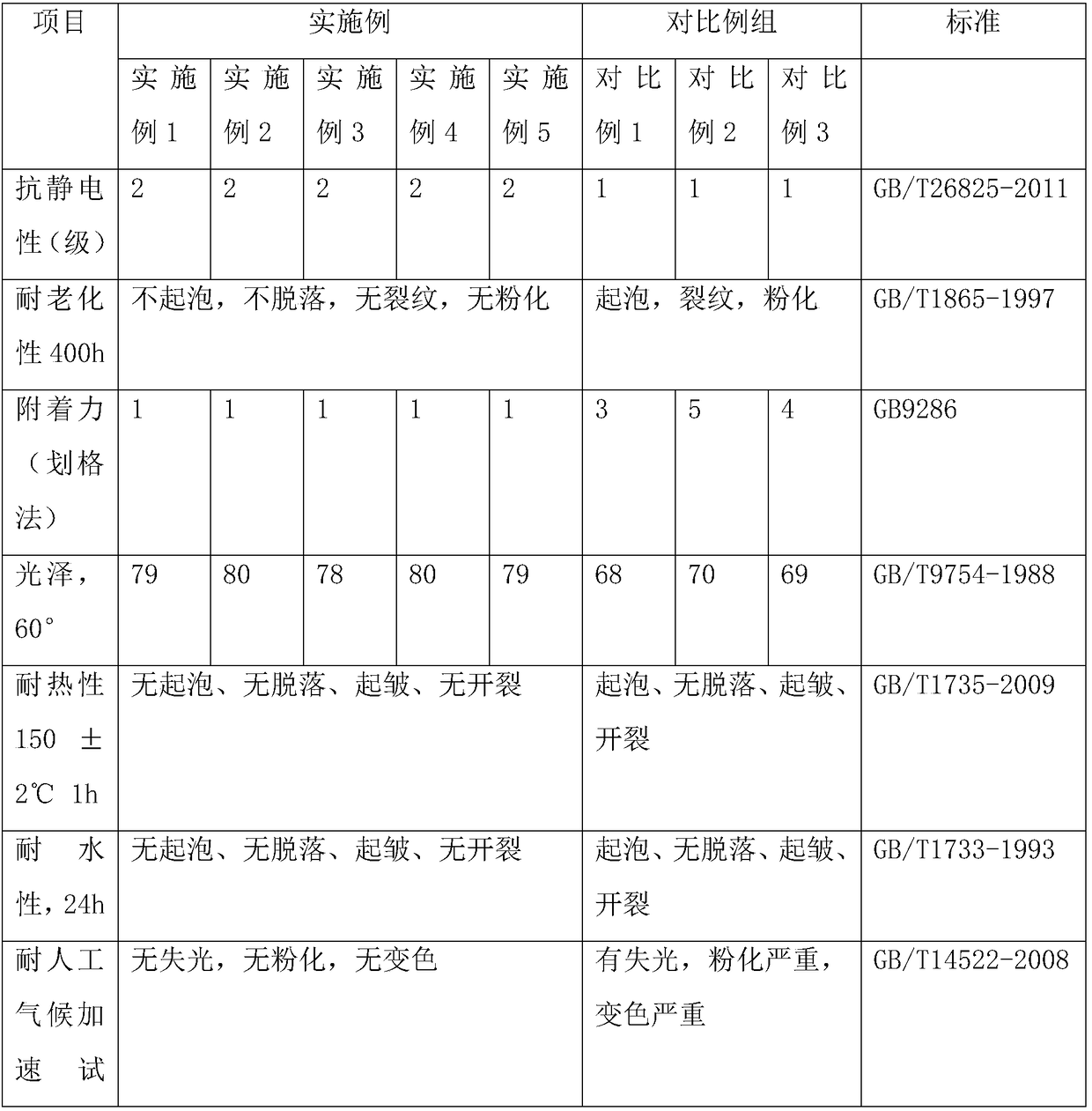

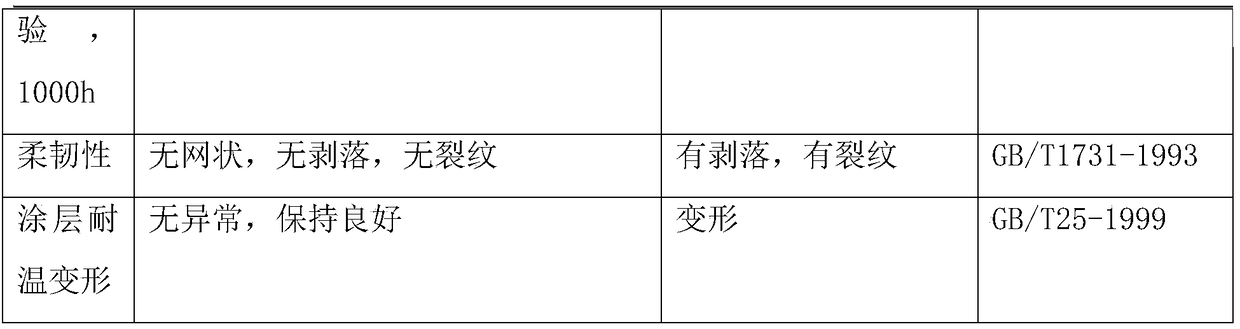

Examples

Embodiment 1

[0041] A new material with antistatic and insulating properties, comprising the following raw materials in parts by weight: 1 part of antistatic synergist, 15 parts of castor oil ethylene oxide, 3 parts of toughening and compatibilizing agent, 10 parts of DBE mixed dibasic acid ester 1 part, N-phenyl-N`-isopropyl-p-phenylenediamine 1 part, 20 parts of modified methyl hexahydrophthalic anhydride, 20 parts of polyether amine curing agent, 2 parts of aminohydrocarbyl silane coupling agent, accelerator 2 parts of agent, 4 parts of lubricant, 5 parts of dispersant.

[0042]The antistatic synergist is: a mixture of nano-zinc oxide particles and nano-antimony-doped zinc dioxide particles; the lubricant is stearic acid, paraffin or ethyl wax; the main components of DBE mixed dibasic acid ester are dimethyl succinate, Dimethyl diacid, dimethyl adipate.

[0043] The preparation method of the modified methyl hexahydrophthalic anhydride is as follows: polyglycol and isomerized methyl hex...

Embodiment 2

[0054] A new material with antistatic and insulating properties, including the following raw materials in parts by weight: 3 parts of antistatic synergist, 20 parts of castor oil ethylene oxide, 4 parts of toughening and compatibilizing agent, 12 parts of DBE mixed dibasic acid ester 3 parts, N-phenyl-N`-isopropyl-p-phenylenediamine 3 parts, modified methyl hexahydrophthalic anhydride 22 parts, polyether amine curing agent 22 parts, aminohydrocarbyl silane coupling agent 3 parts, accelerator 3 parts of agent, 6 parts of lubricant and 7 parts of dispersant.

[0055] The antistatic synergist is: a mixture of nano-zinc oxide particles and nano-antimony-doped zinc dioxide particles; the lubricant is stearic acid, paraffin or ethyl wax; the main components of DBE mixed dibasic acid ester are dimethyl succinate, Dimethyl diacid, dimethyl adipate.

[0056] The preparation method of the modified methyl hexahydrophthalic anhydride is as follows: polyglycol and isomerized methyl hexahy...

Embodiment 3

[0067] A new material with antistatic and insulating properties, characterized in that it includes the following raw materials in parts by weight: 5 parts of antistatic synergist, 25 parts of castor oil ethylene oxide, 5 parts of toughening and compatibilizing agent, DBE mixed two 14 parts of monobasic acid ester, 5 parts of N-phenyl-N`-isopropyl-p-phenylenediamine, 24 parts of modified methyl hexahydrophthalic anhydride, 24 parts of polyether amine curing agent, aminohydrocarbyl silane coupling agent 4 parts, accelerator 4 parts, lubricant 8 parts, dispersant 9 parts.

[0068] The antistatic synergist is: a mixture of nano-zinc oxide particles and nano-antimony-doped zinc dioxide particles; the lubricant is stearic acid, paraffin or ethyl wax; the main components of DBE mixed dibasic acid ester are dimethyl succinate, Dimethyl diacid, dimethyl adipate.

[0069] The preparation method of the modified methyl hexahydrophthalic anhydride is as follows: polyglycol and isomerized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com