Antistatic biaxially-oriented polyester film and preparation method thereof

A biaxially stretched polyester, antistatic technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the decrease of transparency and mechanical properties of BOPET film, adverse effects of film printing effect and durability, The antistatic effect and durability are not ideal, and achieve excellent antistatic properties, improve antistatic stability, and improve transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

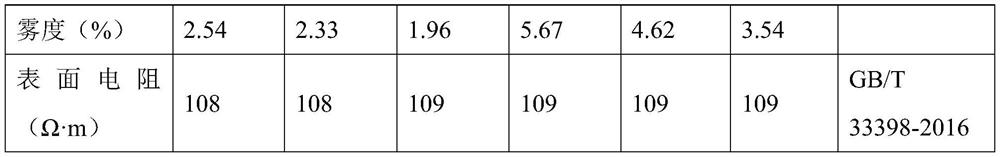

Embodiment 1

[0026] An antistatic biaxially stretched polyester film, consisting of an upper surface layer, a core layer and a lower surface layer, the upper surface layer and the lower surface layer are made of the following raw materials in mass percentage: 30% antistatic PET chips, 70% antisticking masterbatch , the core layer is made of the following raw materials in mass percentage: 98% of film-grade PET chips, 2% of ethylene / sodium methacrylate copolymer;

[0027] Among them, the antistatic PET chips are made by drying 98.5 parts by mass of PET resin and 1 part by mass of polymethacrylic acid at 140-160°C for 4-6 hours, respectively, mixing them with 0.5 parts by mass of antioxidant, and using a twin-screw extruder to It is produced by melt extrusion, and the temperature of melt extrusion is 270-285°C;

[0028] The anti-adhesive masterbatch contains 3300ppm of silica with a particle size of 1.2μm, and the balance is PET resin;

[0029] The ethylene / sodium methacrylate copolymer is S...

Embodiment 2

[0035] An antistatic biaxially stretched polyester film, consisting of an upper surface layer, a core layer and a lower surface layer, the upper surface layer and the lower surface layer are made of the following raw materials in mass percentage: 25% antistatic PET chips, 75% antisticking masterbatch , the core layer is made of the following raw materials in mass percentage: 96% of film-grade PET chips, 4% of ethylene / sodium methacrylate copolymer;

[0036]Among them, the antistatic PET chips are made by drying 98 parts by mass of PET resin and 3 parts by mass of polymethacrylic acid at 140-160°C for 4-6 hours, and mixing them with 1 part by mass of antioxidant, and then using a twin-screw extruder to It is produced by melt extrusion, and the temperature of melt extrusion is 270-285°C;

[0037] The anti-adhesive masterbatch contains 3000ppm of silica with a particle size of 1.4μm, and the balance is PET resin;

[0038] In the ethylene / sodium methacrylate copolymer, the weight...

Embodiment 3

[0042] An antistatic biaxially stretched polyester film, which consists of an upper surface layer, a core layer and a lower surface layer. The upper surface layer and the lower surface layer are made of the following raw materials in mass percentage: 20% antistatic PET chips, 80% antisticking masterbatch , the core layer is made of the following raw materials in mass percentage: 94% of film-grade PET chip, 6% of vinyl ionomer nucleating agent;

[0043] Among them, the antistatic PET chips are made by drying 96.5 parts by mass of PET resin and 1 part by mass of polymethacrylic acid at 140-160°C for 4-6 hours, and mixing them with 0.3 parts by mass of antioxidant, and then using a twin-screw extruder to It is produced by melt extrusion, and the temperature of melt extrusion is 270-285°C;

[0044] The anti-adhesive masterbatch contains 3000ppm of silica with a particle size of 0.6μm, and the balance is PET resin;

[0045] In the ethylene / sodium methacrylate copolymer, the weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com