Vertical wall formwork

A vertical wall and formwork technology, applied in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc., can solve the problem of high investment cost and unfavorable energy saving. Environmental protection, large demand for wood and other issues, to achieve the effect of saving labor costs, simple structure, and increasing the use turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, how the present invention is implemented is further described below with reference to the accompanying drawings and specific embodiments.

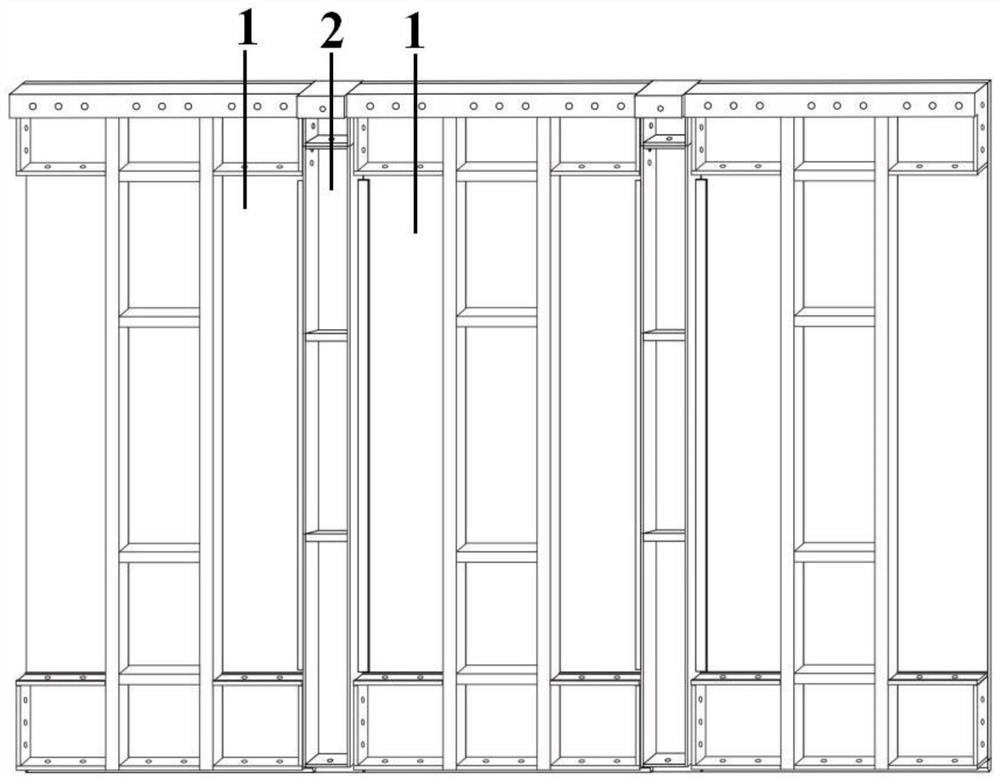

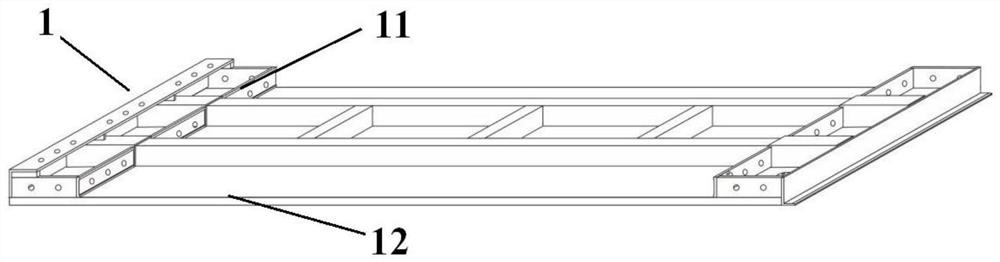

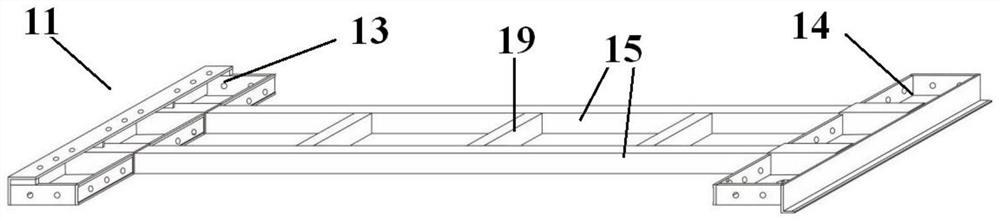

[0038] refer to Figure 1-Figure 3 As shown, the present invention provides a vertical wall formwork, including several frame formwork 1 and several connecting pieces 2; each frame formwork 1 includes a metal frame 11 and a formwork body 12; each metal frame 11 includes The top frame 13 and the bottom frame 14 also include at least two metal pipes 15 which are positioned between the top frame 13 and the bottom frame 14 and are parallel to each other and have the same length, and the two ends of each metal pipe 15 are respectively connected to the top frame 13 and the bottom frame. 14, and the top frame 13, the bottom frame 14 and the metal tube 15 are fixed as one by welding or bolt structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com