Liquid-based sample sheet-making dyeing machine and system and substrate basket carrying method

A dyeing machine and substrate technology, applied in the preparation of test samples, etc., can solve the problems of waste of manpower and material resources, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

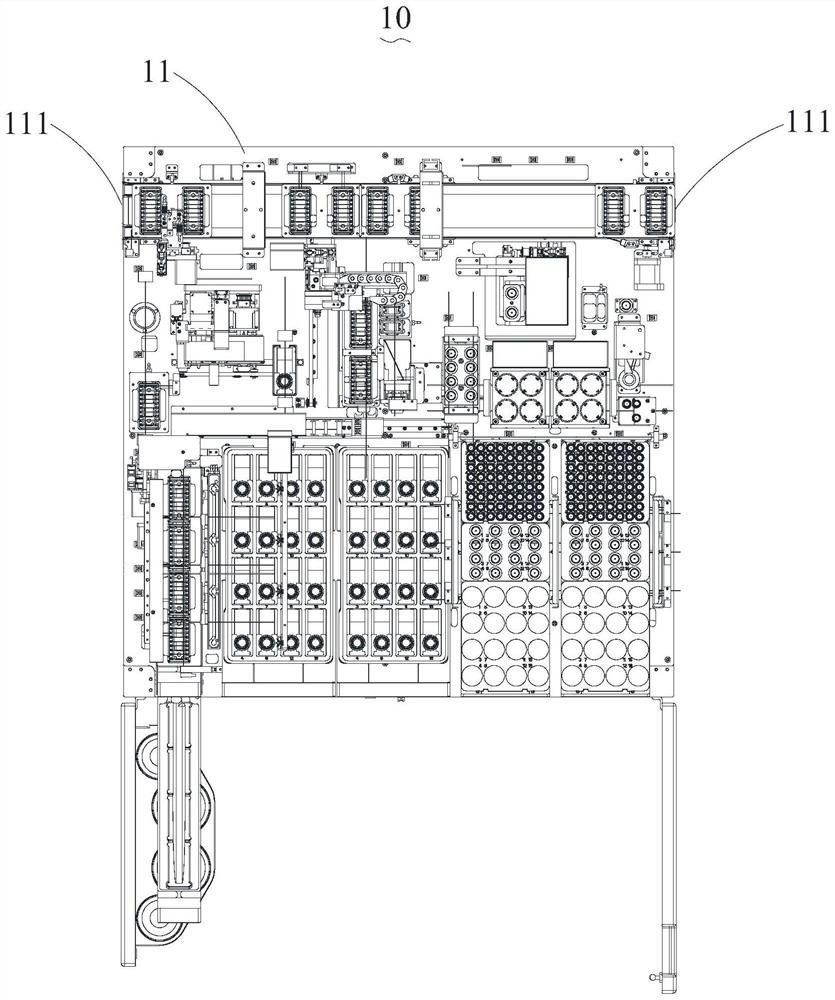

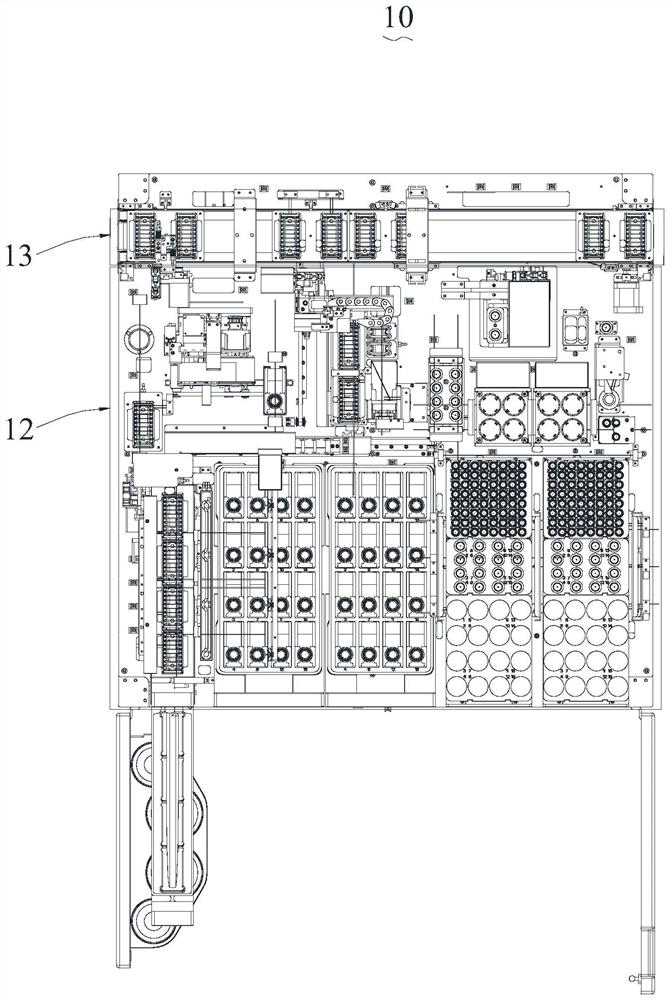

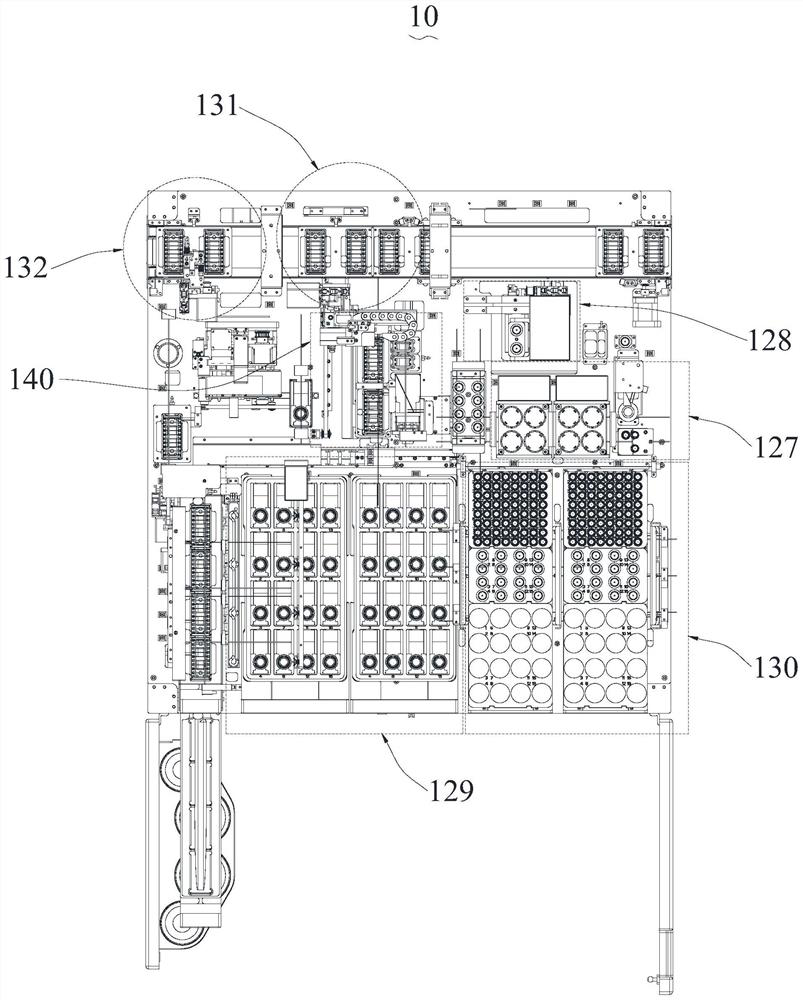

[0041] like Figure 1-5 As shown, a liquid-based sample preparation and dyeing machine 10 provided by the first embodiment of the present invention includes a casing 11, which encloses a accommodating cavity; a device body 12 is located in the accommodating cavity; a series channel 13 is located in the accommodating cavity; The output cylinder 14 can be loaded with liquid for soaking the substrate basket, and is used to carry the substrate basket along the series channel 13 . In a specific application, the device body 12 includes an elution and mixing module 127, a sample centrifugation module 128, a sedimentation and staining module 129, and an elution and mixing module 127 for elution and mixing of the samples in the sample container; the sample centrifugation module 128 is used for centrifuging the eluted and mixed samples; sedimentation and staining module 129, the sedimentation and staining module 129 is used for sedimentation and / or staining of the centrifuged samples. ...

Embodiment 2

[0062] The main difference between this embodiment and the first embodiment is that the main body of protection is different. Specifically reflected in:

[0063] refer to figure 2 , 3 As shown in and 5, a method for carrying a substrate basket includes the above-mentioned liquid-based sample preparation dyeing machine 10 and a series channel 13 to drive an output cylinder 14 loaded with anhydrous ethanol solution and / or xylene solution to move to the substrate The basket operation position 131 performs the loading and / or unloading of the substrate basket; the serial channel 13 drives the output cylinder 14 to transport from the serial channel 13 to the preset equipment. In specific applications, the series channel 13 drives the output cylinder 14 loaded with anhydrous ethanol solution and / or xylene solution to be transported from the series channel 13 to other equipment, or the series channel 13 drives the unloaded absolute ethanol solution and / or xylene solution. The outp...

Embodiment 3

[0069] The difference between this embodiment and Embodiment 1 and Embodiment 2 mainly lies in the main body of protection. Specifically reflected in:

[0070] refer to figure 2 As shown, this embodiment will introduce a liquid-based sample processing system, which connects at least two liquid-based sample preparation and dyeing machines 10 in series, so as to break the bottleneck of production efficiency and further improve the efficiency of the detection process . As we all know, in the biological sample detection process, the production process has more steps and longer time than the process of sealing and reading. Therefore, by providing a plurality of liquid-based sample preparation and dyeing machines 10, which are integrated and connected in series in the system, the system can automatically complete the preparation, sealing and reading, while reducing the waiting time of the sealing machine and the reading machine. , shorten the total time of the detection process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com