Gas-liquid pressurization type pinion press-fitting machine

A gas-liquid pressurization, pinion technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unobstructed gear, low replacement efficiency, damage, etc., to improve the safety of use and ensure output efficiency , The effect of improving the efficiency of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

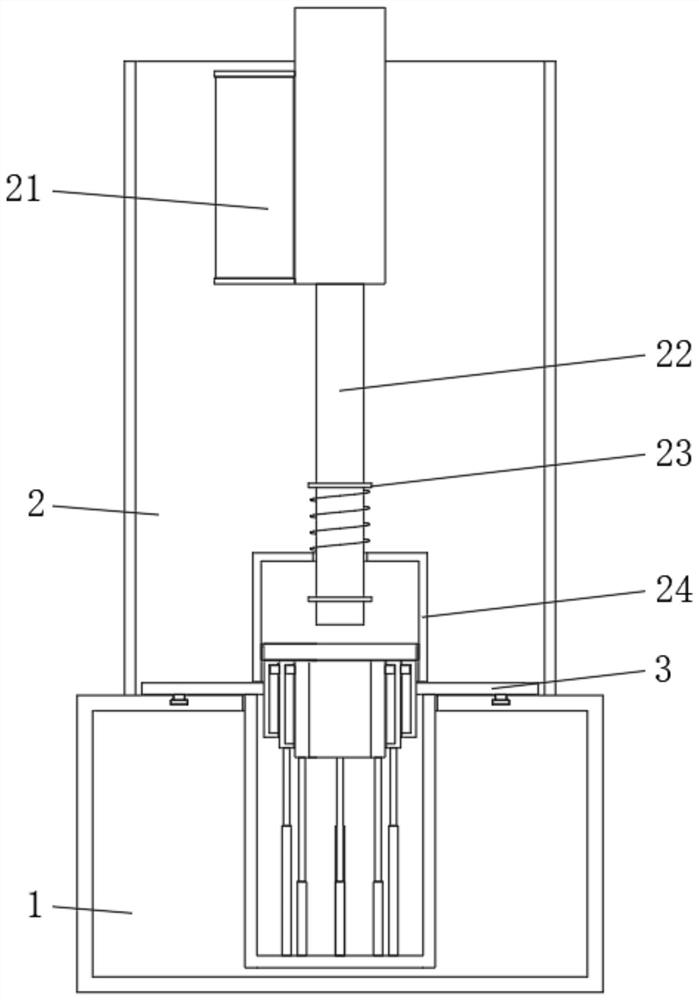

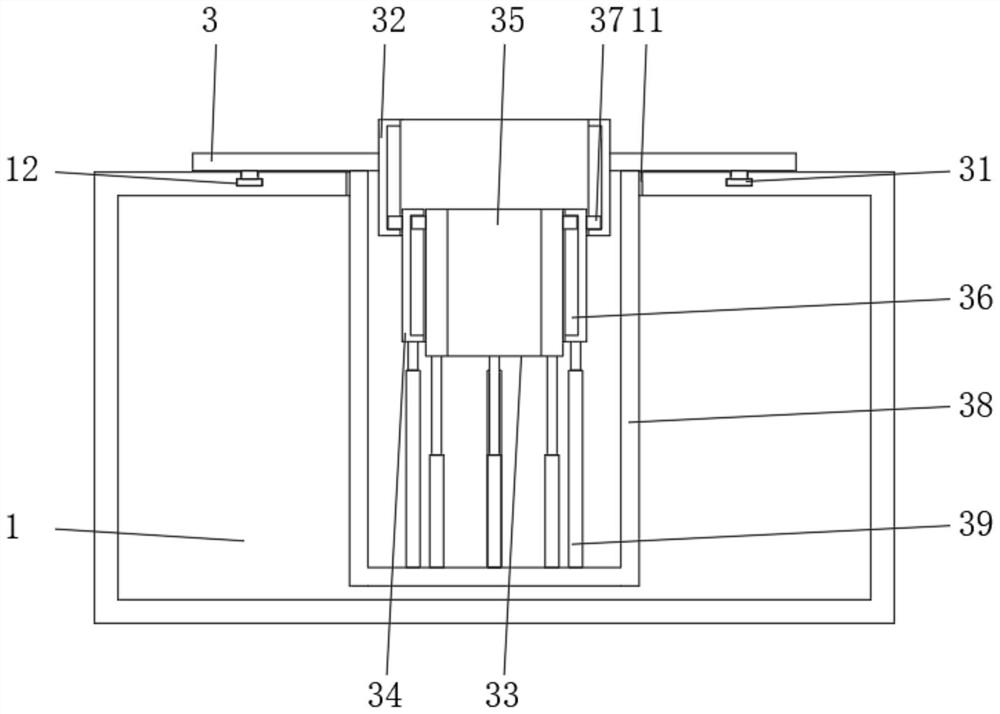

[0024] Embodiment 1: A gas-liquid pressurized pinion press, comprising a base 1, a connecting plate 2, a supporting plate 3, a protective cover 24 and a first connecting block 32, and a connecting plate 2 is installed on one side of the outer wall of the upper end of the base 1, A movable hole 11 is formed on one side of the outer wall of the upper end of the base 1, and a chute 12 is formed on the outer walls of the base 1 away from the movable hole 11 on both sides. 32. The first connecting block 32 is provided with a second connecting block 33, and the second connecting block 33 is provided with a third connecting block 34. The outer walls of both sides of the connecting plate 2 are equipped with a safety grating body 27. The safety grating body 27 is For the photoelectric safety protection device, the safety grating body 27 is a kind of photoelectric device to prevent personnel from approaching the mobile machinery, which can avoid casualties.

[0025] The first connection...

Embodiment 2

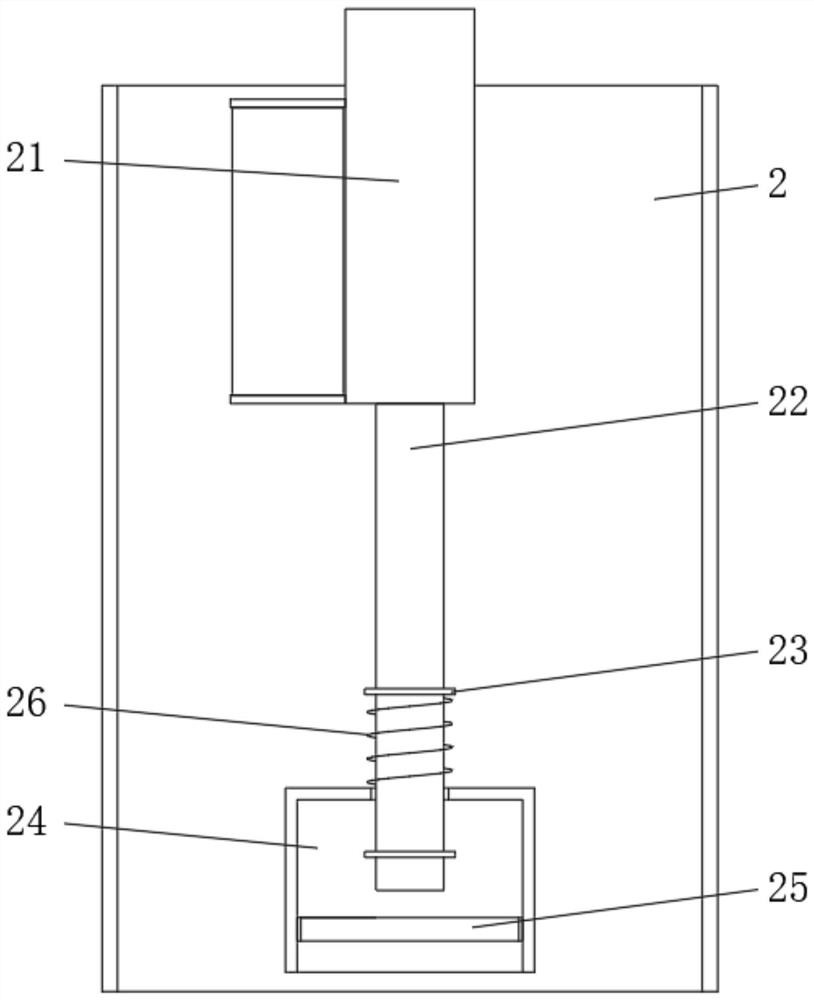

[0029] Embodiment 2: A gas-liquid pressurized pinion press, comprising a base 1, a connecting plate 2, a support plate 3, a protective cover 24 and a first connecting block 32, and a connecting plate 2 is installed on one side of the outer wall of the upper end of the base 1, A movable hole 11 is formed on one side of the outer wall of the upper end of the base 1, and a chute 12 is formed on the outer walls of the base 1 away from the movable hole 11 on both sides. 32, the first connecting block 32 is provided with a second connecting block 33, the second connecting block 33 is provided with a third connecting block 34, the outer walls of both sides of the connecting plate 2 are installed with safety grating bodies 27, and the upper end of the inner wall of the connecting plate 2 is A pusher body 21 is mounted on the side.

[0030] A connecting cover 38 is installed on one side of the outer wall of the lower end of the support plate 3. The connecting cover 38 is located inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com