Blanking station convenient to supplement materials in time

A technology of feeding station and feeding material, applied in the field of feeding station, can solve the problem of material cut off at feeding station, and achieve the effect of convenient feeding, avoiding feeding cut off in the middle, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

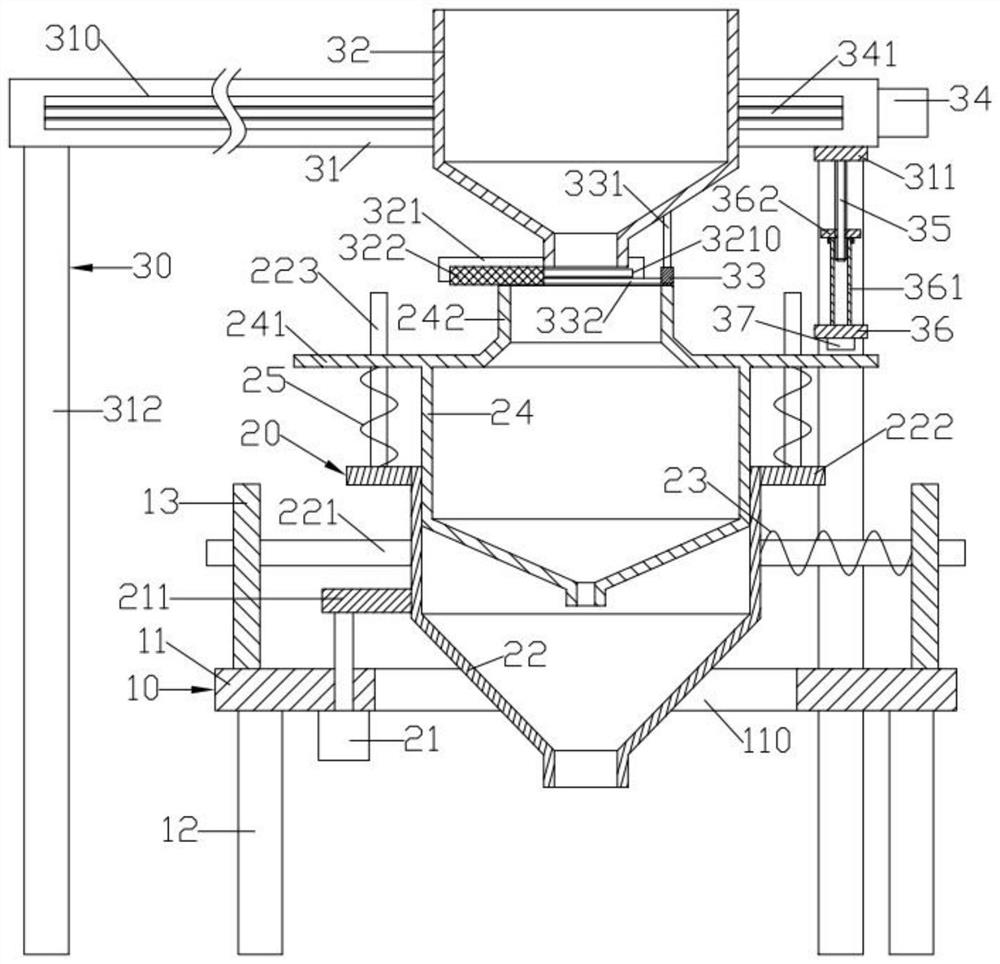

[0014] like figure 1 As shown in the figure, a feeding station for convenient and timely feeding includes a bracket 10, a feeding unit 20 and a feeding device 30; the bracket 10 includes a horizontal support plate 11; the middle of the horizontal support plate 11 is formed with upper and lower openings. 110; a plurality of evenly distributed support feet 12 are arranged on the bottom surface of the horizontal support plate 11; the blanking unit 20 includes a blanking outer hopper 22 arranged on the left and right horizontal supporting plates 11 in a left and right reciprocating motion; the blanking outer hopper 22 is vertically The lowering inner hopper 24 is inserted and the lowering inner hopper 24 is vertically elastically arranged; the upper end of the lowering inner hopper 24 is formed with an upper sealing plate 241; the upper end of the upper sealing plate 241 is formed with an upper connecting pipe 242; The device 30 includes a pair of left and right guide plates 31 sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com