Dust removal system and dust removal process method for preparing acetylene from wet calcium carbide

A dust removal system and control system technology, which is applied in the field of safe and environmentally friendly digestion of calcium carbide dust, to achieve the effects of reducing inspection and maintenance costs, improving inspection and maintenance efficiency, and reducing fire risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

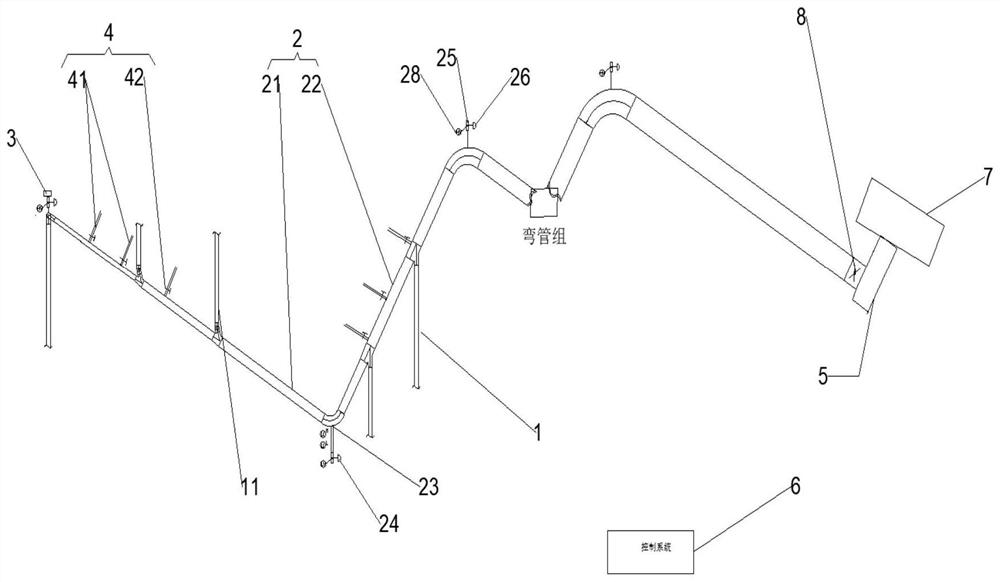

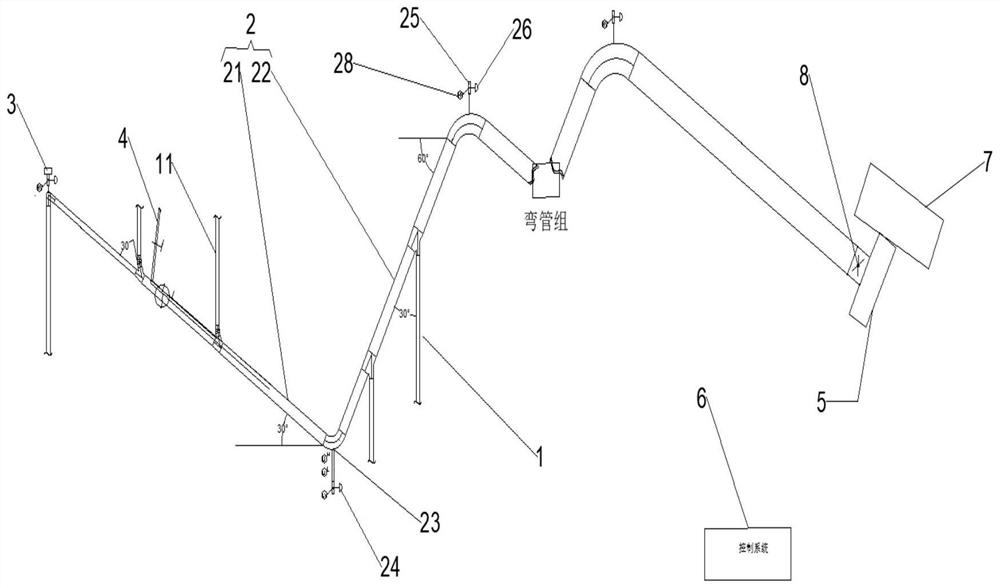

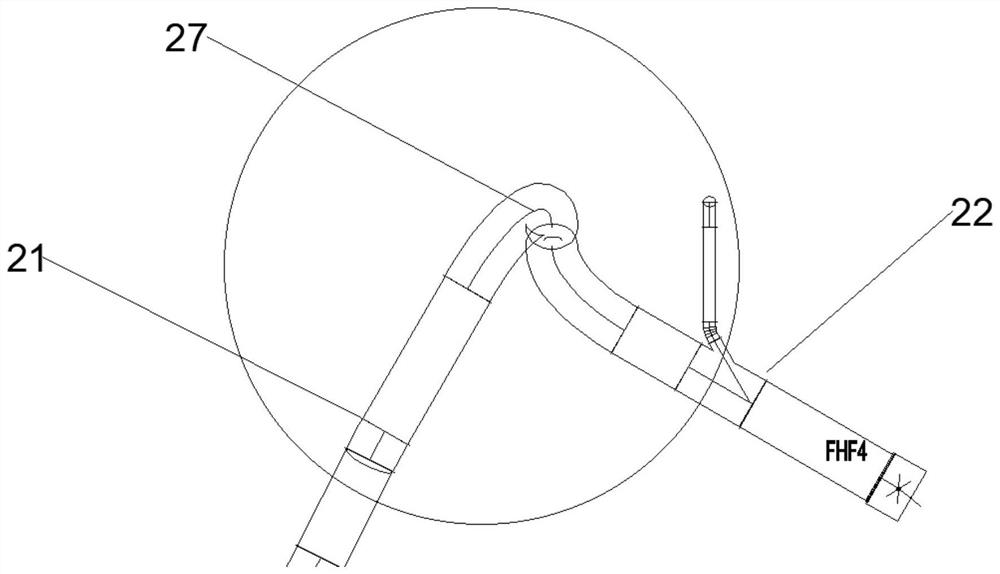

[0041] like Figure 1 to Figure 7 As shown, a dust removal system for preparing acetylene from calcium carbide, the dust removal system includes a dust suction branch system 1, a conveying pipeline system 2, a gas protection system 3, a dust material cleaning system 4, a dust material collection system 5, and a control system 6 , emptying system 7, fire protection system 8,; the output end of the dust collection branch system 1 is connected with the conveying pipeline system 2; it is used to collect the calcium carbide dust of the crusher; the conveying pipeline system 2 is used to transport calcium carbide Dust gas; the gas protection system 3 is used to replace the acetylene gas in the calcium carbide dust gas in the conveying pipeline system 2 with an inert gas; the dust cleaning system 4 is used to clean the dust in the conveying pipeline system 2 Calcium carbide dust; the dust collection system 5 is arranged at the end of the conveying pipeline system 2; the emptying syst...

Embodiment 2

[0049] like Figure 2 to Figure 7 As shown, a dust removal system for preparing acetylene from calcium carbide, the dust removal system includes a dust suction branch system 1, a conveying pipeline system 2, a gas protection system 3, a dust material cleaning system 4, a dust material collection system 5, and a control system 6 , emptying system 7, fire protection system; the output end of the dust collection branch system 1 is connected with the conveying pipeline system 2; it is used to collect the calcium carbide dust of the crusher; the conveying pipeline system 2 is used to transport the calcium carbide dust containing Gas; the gas protection system 3 is used to replace the gas containing calcium carbide dust in the conveying pipeline system 2 with the atmosphere; the dust cleaning system 4 is used to clean the calcium carbide dust in the conveying pipeline system 2; the dust The material collection system 5 is arranged at the end of the conveying pipeline system 2; the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com