Additive feeding equipment and control method thereof

A technology of equipment control and additives, which is applied to the control devices of washing machines, textiles and papermaking, and household appliances. It can solve the problems of limited capacity, cumbersome refilling process, inability to wash and care special or high-end clothes, and improve response. Speed, Simplify the Processing Process, Improve the Effect of Nursing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

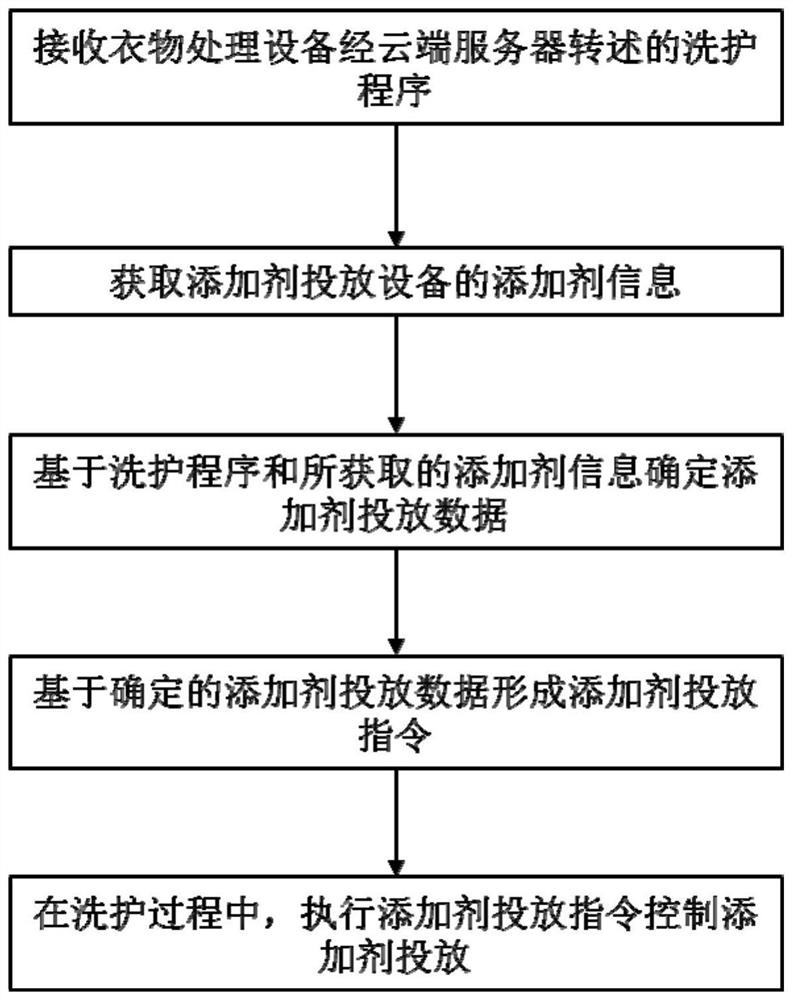

[0050] like figure 1 As shown, the embodiment of the present invention provides a control method for the additive injection device 200, which includes the following steps:

[0051] Step 1: Receive the washing and care procedure recited by the clothing processing device 100 via the cloud server 300;

[0052] Step 2, obtaining the additive information of the additive delivery device;

[0053] Step 3, determine the additive delivery data based on the washing and care program and the obtained additive information;

[0054] Step 4, forming an additive delivery instruction based on the determined additive delivery data;

[0055] Step 5, in the washing and care process, execute the additive injection instruction to control the additive injection.

[0056] In this embodiment, the additive injection device 200 forms an additive injection instruction based on the determined additive injection data, and automatically injects the additive into the clothes treatment device 100, so that th...

Embodiment 2

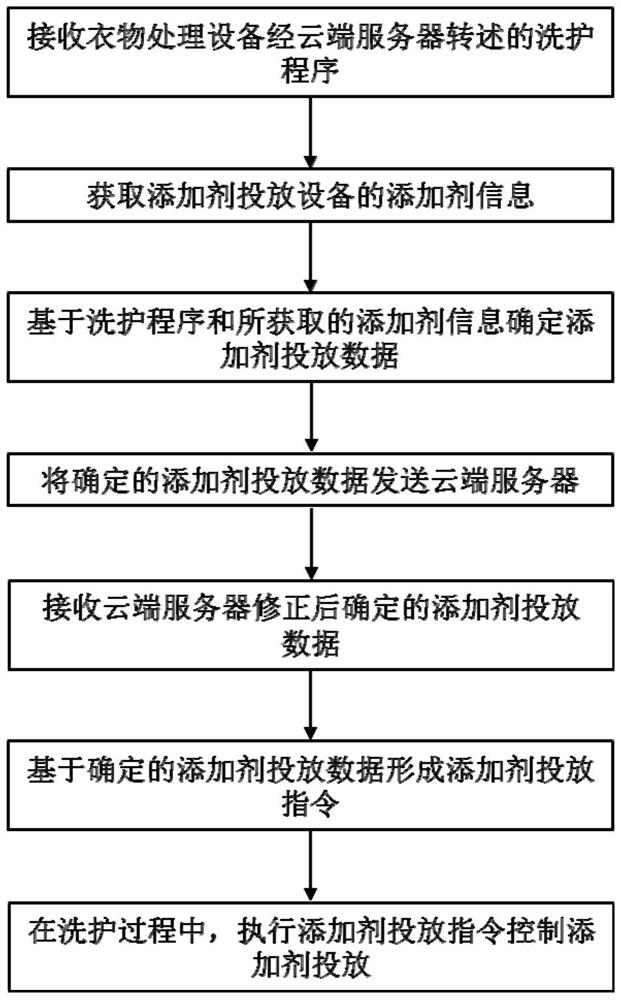

[0075] like figure 2 As shown, this embodiment is a further limitation of the above-mentioned first embodiment: after step 3 and before step 4, it also includes the following steps:

[0076] Step S11: sending the determined additive delivery data to the cloud server 300;

[0077] Step S21 : Receive the additive delivery data determined after correction by the cloud server 300 .

[0078] In this embodiment, the additive injection device 200 associates and stores the additive injection data corresponding to the real-time additive injection instruction and the cleaning program on the cloud server 300, so as to form an additive injection database corresponding to the cleaning program.

[0079] In this embodiment, if there are multiple sets of additive delivery data determined based on the washing and care program and the acquired additive information, or the additives that can be delivered by the additive delivery device 200 do not include the additives involved in the additive ...

Embodiment 3

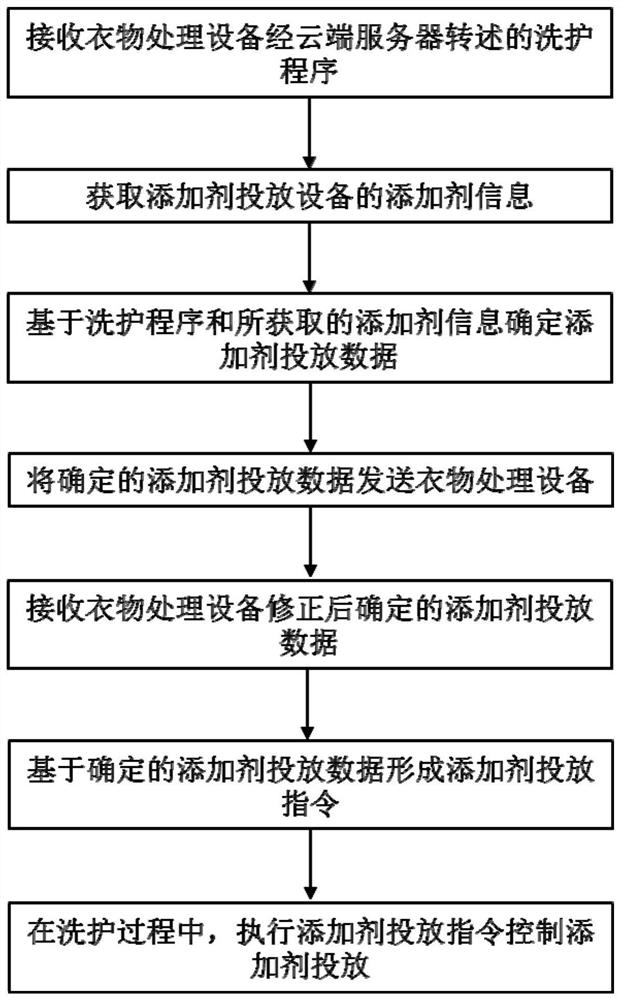

[0086] like image 3 As shown, this embodiment is a further limitation of the above-mentioned first embodiment: after step 3 and before step 4, it also includes the following steps:

[0087] Step S12: sending the determined additive delivery data to the laundry treatment device 100;

[0088] Step S22: Receive the additive dosage data determined after correction by the laundry treatment device 100.

[0089] In this embodiment, the additive delivery device 200 transmits the determined additive delivery data to the laundry processing device 100 via the cloud server 300 , and receives the corrected additive delivery data transmitted by the laundry processing device 100 via the cloud server 300 .

[0090] In this embodiment, the additive injection device 200 associates and stores the additive injection data corresponding to the real-time additive injection instruction and the cleaning program on the laundry processing device 100, so as to form an additive injection database corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com