Bulletproof roof top plate and manufacturing method

A technology with a top plate and one side of a bullet plate, applied in chemical instruments and methods, protective clothing, protective equipment, etc., can solve the problems of indoor personnel, continuous explosion of ammunition, explosion, destruction of people and objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

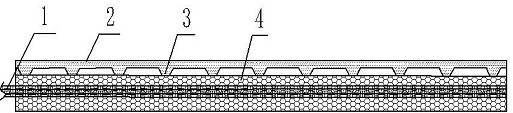

[0009] Example 1: refer to the attached figure 1 . A bulletproof roof roof plate, one or more layers of aramid III loom cloth 1 is coated and cured by high-strength, high-toughness, and high-hardness water-based resin powder 4 to form a bullet-proof plate, and the high-hardness, high-tenacity and high-elasticity plate 3 is compounded on one side of the bulletproof plate. .

Embodiment 2

[0010] Example 2: On the basis of Example 1, the high-hardness, high-toughness, and high-elasticity plate has a plurality of high-elasticity columns 3 on one side. The high-elasticity column 3 is a polymer elastic column, or a high-elasticity spring.

Embodiment 3

[0011] Example 3: On the basis of Example 1 or Examples 1 and 2, the aramid III loom cloth can be replaced by the ultra-high molecular weight polyethylene fiber loom cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com